Hydraulic Press Brake

Get Price Quote

These are heavy duty Hydraulic Press Brake machines available in a wide range of capacities ranging from 20 tons to 500 tons in pressure and job sheet size from 1500 mm to 5000 mm in length with 1.62mm to 20 mm in thickness. The machines are supplied complete with all standard accessories including the following: Main Drive Motor Electrical control panel with selection of AUTO, INCH and Single Cycle AUTO mode of operation Pair of foot switches Pair of lifting links Fine stroke adjustment rod with limit switches Front operated manual back gauge with fine setting knobs One suitable 5 way die and universal upper blade- segmented or full length Centralized lubrication system with hand pump Pair of sheet supports Bending chart Maintenance tool kit Comprehensive instruction & maintenance manual with CD Many optional accessories are offered such as: Motorized deflection compensation unit Ram tilting arrangement Hardened and ground tools & special toolings Motorized back gauge with DRO Sliding sheet supports with swing away stoppers for front gauging. Hydraulic tool clamping Photo electric finger safety guards We also offer NC and CNC Synchro Press Brakes. Kindly ask for details with your requirements.

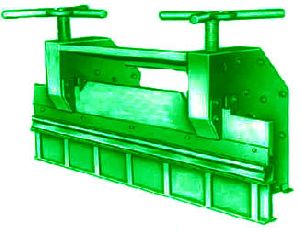

hand press brakes

Get Price Quote

Hand operated all steel welded construction press brake ideally suitable for bending sides of rolling shutters, cupboard, cabinets, trays, boxes and many other objects provided with bending die with various size of grooves having following specifications.Bending Width :4', 6', 7', 8' Capacity in M.S. :1/16", 1/8"

Best Deals from Press Brakes

Hydraulic Press Brakes

Get Price Quote

We deals in supplying of wide range of Hydraulic Press Brakes.

Mechanical Clutch Bending Press Brakes

Get Price Quote

Press Brakes are designed and developed through years of experience in sheet metal working machines. Press Brakes are widely accepted in industries for continuous production runs and in areas requiring accuracy and repeatability coupled with high production. Frame : Frame is of robust fabricated steel construction of rigid and interlocked design. It is stain-free and supports the ram and bed against desired deflection under permissible loading condition. Ram and bed : Made from steel plates of suitable thickness, machined for straightness and parallelism of working surfaces. Ram is guided and supported throughout the stroke by accurately machined guideways. Drive system : Power is transmitted to the ram through two individual gear drives for uniform load distribution throughout the length. This also reduces the torsional stresses on the eccentric shaft. Electric motor used is of sufficient H.P. which reduces slowdown of fly wheel and increases energy available per stroke. The gear and pinion are made out of carbon/alloy steel. Ram Adjustment : Motorised ram adjustment through a simple drive mechanism, faciliates quick bending angle adjustment. Angular ram adjustment made simple by incorporating a spring loaded dog clutch. Clutch and brake : All series of press brakes are provided with high-torque tow-inertia friction clutch synchronised with heavy duty mechanical brake ensuring immediate braking of ram on releasing the pedal Clutch operating levers are designed in such a way that minimum enraging force is required at the pedal. Special Features : Connection link mounted on crank shaft for uniform load, separate Drive system for each connection link, Sufficient H.P Normal torque motors provided. Boltless pedal mounted on hexagonal bar. General purpose V-Block and punch supplied as standard accessories. Pneumatic Clutch & Brake : Electrically controlled & Air operated Clutch & Brake combine unit permits high frequency of ooperation and more Flywheel energy for work. Wear on Clutch & Brake is automatically compensated & no adjustment is necessary. Surge Tank, Filter, Regulator, Air Lubrication Unit, Pressure Switch etc. are incorporated. Pneumatic Counter Balancer are provided to Counter the Weight of Slide & Tooling which help in taking up the bearing clearances and ease Slide adjustment. Standard Accessories : Standard V-block and Punch, Back Gauge, Electrical consist of Electric Motor, Wiring, Control Panel, V-belt, Push Button Starter, Motor pulley, Motor Mounting Bracket, Pedal, Flywheel & Gear Guards, Stroke Counter, Lubrication Pump & Instruction Manual. Optional Accessories : Automatic Pump Lubrication System, Goose Neck Punch, & other toolings (Drawing required).

power press brakes

Get Price Quote

- All steel construction - Manual Ram adjustment on models RPB-1 and RPB-2 - Motorized Ram adjustment on models from RPB-3 to RPB-8 - Mechanical friction clutch

Mechanical Press Brake

Get Price Quote

FRAME CONSTRUCTION : Frame Is Made of steel fabricated construction of interlocked robust design, machines are constructed with safeguard against undesired deflections and breakage. The frame distributes the stresses, supporting the bed directly on the frame. The double support shoe of frame gap provides extremely high rigidity, alignment, accuracy and keeps frames structure at right angles to the bed. RAM & BED : Ram and bed are straight and parallel of both the working surface under the rated load. The bed is accurately machined and upper surface is grinded to keep the die in correct alignment. The ram is guided and supported throughout the stroke by accurately machined guide ways. STANDARD ACCESSORIES Foot Pedal and Die Block Lifting Link Self lubricant System Motor Pulley Fly wheel & Gear guard Stroke COunter Standard "V" Block Punch Motor Mounting Bracket OPTIONAL ACCESSORIES Motorized Back Gauge Automatic Lubricant System Vee-Belts Electric Motor & Starter / Control Panel Board Various Type of Die & Punch Foundation Bolts

Engineering machines

Get Price Quote

Engineering machines, Geared Motor, Centrifugal Pumpset, Dewatering Pump

Hydraulic Press Brakes

Get Price Quote

Hydraulic Press Brakes, Floor model Metal Sheet Shearing Cutting Machine

Press Brakes

Get Price Quote

Press Brakes

bending

Get Price Quote

bending, SHEET STEEL FABRICATION, Laser Cutting, Welding