Cold Press Oil Extraction Machine

Get Price Quote

1 Pieces (MOQ)

Cold Press Oil Extraction Machine A cold press oil machine works by crushing/pressing the oil materials at low temperature via screw device, without pre-treating the materials. We manufacture Cold press oil machinery for organic oil extraction from all kind of oil bearing seeds like groundnut oil (peanut oil ), sesame oil, coconut oil, mustard oil.etc., Cold press oil extraction is like the Traditional oil extraction technology widely used in India. Benefits of Cold pressed oil: It produces cholesterol-free oil Oils are not refined, processed or deodorized in any way, thus producing pure oil No harmful solvent residues No added preservatives or chemicals House natural antioxidants like phosphatides (e.g. lecithin) & tocopherols (e.g. vitamin E) It retains natural odour & flavour Small load, energy saving and low noise

Hydraulic Press Brake Machine

1,000,000 Per Piece

1 Piece (MOQ)

Best Deals from Pressing Machine

Press Assembly Machine

Get Price Quote

1 Piece (MOQ)

Hydraulic Gold And Silver Capsule Press Machine

Get Price Quote

1 piece (MOQ)

Manual Hand Press Chapati Making Machine

18,000 - 19,000 Per Piece

1 Piece (MOQ)

Filter Press Machine

150,000 Per Piece

1 Piece (MOQ)

PROFILE PRESS BREAK MACHNE

Get Price Quote

1 Container (MOQ)

HYDRAULIC PRESS BREAK LENGTH UPTO 4000 MM WIDTH UPTO 300 MM THICKNESS UPTO 12 MM

Rotary Tablet Press Machine

265,000 Per Piece

1 Piece (MOQ)

Standalone Impact Press Machine

Get Price Quote

1 Piece (MOQ)

We are the one stop shop in market for availing precision engineered Standalone Impact Press Machine. Impact Press Machine, available with us, is robustly constructed in accordance with high quality standards. The Standalone Impact Press Machine is very easy to operate and is preferred for its user-friendly operations. Details Easy - to - adjust impact force. Automatic compensation for different workpiece thickness ( note : Airline Pressure is only compressing the spring - not for determining impact force). Higly versatile : Ideal for Light Assembly Work and for Sheet Metal Work (Rivetting, flaring, Piercing, Shearing, Bending ..... plus many more operations). Out put speed matches speed of manual loading. Lowest rejections - even in precision jobs. Far longer tool / die life ! Adaptable for automation with approxiate fixtures tools and dies. Tools with cylindrical shanks are clamped by a collet in tool-holder. Arm can be set and clamped at any height on the column. Fine-ground working table surface with T-slots for speedy fitting of work - holding fixtures. All sliding parts are made of selected steel hardened and ground.

HYDRAULIC SHEET BENDING PRESS C-TYPE

Get Price Quote

Bending pressing is a manufacturing process to give shapes to sheet metals or ductile materials.Here the product/material which is to be pressed is placed over a die block and die block presses the sheet to form a particular shape. There are three types of bending, coining, bottoming and air bending. Products like electrical enclosures are made using sheet bending press. The presses are supplied as complete units fitted with high & low pressure ,pump with electric motor, pressure gauge, limit switch, control valve ,micro switch, roller switch and oil tank connecting pipes.

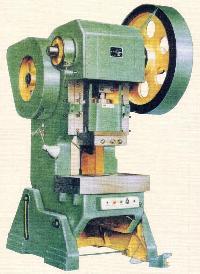

Power Press Machine

Get Price Quote

1 piece (MOQ)

To manufacture these machines, we source high-end quality of metals from authentic vendors of the market. we use steel of heavy cross section to construct the frame of these press machines. Acknowledged for their high load bearing capacity, greater strength and long working life, we are offering these machines to our clients without any delay. Power press machine is suitable for metal forming and deep drawing applications.

Press Break Machine

Get Price Quote

Industrial Hydraulic Press Machine

200,000 Per Piece

150 TON HYDRAULIC H TYPE PRESS MACHINE

635,000 - 800,000 Per piece

1 Piece (MOQ)

Vaccum Press Casting Machine

Get Price Quote

The fully automatic casting machine vc 450 this machine is designed for: • casting of jewellery and other filigree parts • for permanent use • for certified production processes constructed on base of the vc 400, the vc 450 is equipped with a completely new generator and a program control system with full read out lcd display. With help of the step-by-step display information and many automatic functions the handling of the machine is very easy even for less experienced users. The program control for 25 different casting cycles allow reproducible and consistent casting results. new program control system : new control panel with full text lcd display, all programs & parameters are very easy & convenient to set. 100 casting programs guarantee fast operation and consistent casting results. Parameters are pre programmed for all major alloys, e.g. For ags, aplha plus, heraeus, legor, and pandora alloys. In practice this mean: from the first flask, you can expect good casting results without carrying out expensive pretests. the comfortable lcd display and control system: 20 casting programs allow for the individual setting of relevant process parameters before casting and their storage for recurrent castings – which is important for quality certified processes, high process reproducibility and for an economical production with fast casting cycles. Performance power max. electrical connection maximum temperature capacity crucible volume for use of flasks up to handling+control maximum pressure program control dual temperature control automatic flask & chamber lift turbulence reduction software. quality management rs232, diagnostic system, remote service data printer gsm modern accessories sinrering kit (for dissusion bonding) granulation tank

Caps Placing and Pressing Machines

Get Price Quote

The descending Capping head hold bottle’s neck with desired pressure. The Pressing is done with the help of specially made up and down hammering system.

Plastic Bottle Baling Press Machine

Get Price Quote

1 Piece (MOQ)

Plastic bottle baling press machine is specially designed for pressing PET bottles, plastic materials. The Baler produces bales of 100-200 Kg and withholds daily production capacity of 1-3.5 Tons/day. High productivity and long life service is guaranteed with our plastic bottle baling press machine. The Baler Is Featured with Electric & Lever Controlled System. The machine is enhanced with automatic switches and levers, making it cost and time efficient. Every Techno Hydraulic Balers are designed for years of Reliable, Trouble Free Experience. The Size & Weight Of The bales can Be configured as per the requirement as various merchants has various Facilities.,

Heat Transfer Press Machine

Get Price Quote

Innovative Heat Press Technology Made in USA Stahls’ Hotronix® designs, engineers and manufacturers the World’s most innovative and technologically advanced heat press machines with one goal in mind – to exceed customer expectations at a competitive cost. The Hotronix®Dual Air Fusion™ is a heat press that allows a single operator to decorate garments nearly 50% faster when compared to any swinger- style heat press. The Dual Air Fusion’s separate A and B work stations provide an efficient and dynamic range of work flows. It allows you to individually programme your work stations with unique time, temperature and pressure Settings for different heat transfer applications. For decorators serious about Direct-to-Garment printing, the Dual Air Fusion is the no-nonsense solution. Its technology turns the multi-step task of garment decoration into a single streamlined process. Programme your A station for pre treatment, and your B station for post-cure, and you will see how the speed and quality of your prints improve. Combine this type of versatility with our wide selection of Quick Change Platen and option laser alignment system, and it’s easy to see why the Dual Air Fusion is the ultimate solution for anyone serious about taking technology, performance – and profit – to a new level. AccessoriesAs an Experienced partner in the field Of Textile Printing, Stahls offer you all the accessories you will need to complete a Professional Finish. Interchangeable Lower Platens Hottronix® Auto open Series //Sprint®Mag7” (17.50 cm)6” X 10” (15cm X 25cm)8” X 10” (20cm X 25cm)

Cap Pressing Machine

Get Price Quote

We are offering cap pressing machine automatic cap pressing machine (jet- cappr-auto) machine name automatic cap pressing machine model no jet- cappr-auto applications for the capping machine talcum powder bottles advantages of automatic capping machine simple design. high speed operation. low power consumption. main features of capping machine -“no container - no cap arrangement". online / offline operation can possible. our machines are also for applying round or other shape of glass, plastic, pet, ldpe, and hdpe bottles with the aid of change parts or capping head. minimum labour requirement. the machine has output up to 60 bottles/min depending on the size and shape of the bottle. online operation can be possible with liquid or powder filling line. general specification power input 1 kw, 3ph, 440v, 50hz motor • machine main motor- motor 2 h.p, bonfigloli, hindustan motors • conveyor- gear motor 0.5h.p- bonfigloli total power 1.5 kw air consumption 4-5 cfm speed 60 bpm (depending on the size and shape of the bottles) dimensions 2400 (l) x 1800 (w) x 2000 (h)

Adept Double Rotary Tablet Press Machine

3,500,000 Per Piece

1 Piece(s) (MOQ)

We have been manufacturing Double Rotary Tablet Press (two hoppers) for more than 25 years and our main aim is to provide the pharmaceutical industry a well designed sturdy Tablet Press with all the GMP features which is simple to use. The double sided Tablet Press has a provision of variable frequency drive (VFD) that facilitates smooth take off without any jerky motion during initial starting of the machine. While designing the Tablet Press, we have given major emphasis towards safety as well as reliability and durability of machine components and this concept can be understood from the following key features that are provided on the Adept Double Sided Tablet Press. Safety spring (compression type) is provided to avoid overload on punches and this provision also acts as a tonnage indicator. In order to reduce punch jamming occurrences, tunnel tracks are provided on the cam to ensure positive lifting of the Upper Punch thereby reducing wear and tear on the cam as well. All care has been taken to ensure use of good quality grade casting when manufacturing Turrets in order to eliminate cracks. Detachable gear ring is used to minimize replacement costs. An electronic timer is provided on the Tablet Press for the auto-lubrication mechanism to ensure that right quantity of oil is regularly supplied to all the lubrication points on the machine to facilitate smooth operation. Setting of compression pressure and tablet weight control can be very easily done from the control panel provided on the front side of the Tablet Press without any need to open the machine doors. AC speed control (VFD) mechanism is fitted on the control panel which makes the operation smooth and also very easy for the operator to work with. The 5 H.P. VFD speed control gives the operator a wider choice of speed range that facilitates the shop floor to work with all types of powders which has different flow-ability characteristics to achieve optimal tablet output from this Tablet Press. With minor attachments (optional) Adept Double Rotary Tablet Press can be used to produce Bi-Layer Tablets also.