Filter Press

Get Price Quote

The unfiltered liquid is fed into the filter under positive pressure, where liquid travels in downwards direction and finds its way through opening on sides of the Filter Plates. As the liquid pressure increases, the Filter media holds the foreign particles and allows only clear filtrate to pass through the central channel formed by interlocking pressure cups to the outlet. Filtration is continued until the cake holding capacity of the unit is reached or until the filtrate rate becomes too slow owing to cake resistance. Innovative Features : • Horizontal Plate Filter Press is enclosed construction, preventing evaporation, oxidation, leakage and fumes escaping from product. • Filter plates are available in two sizes. Deep plate for large percentage of cake holding capacity and Shallow plate for small percentage of cake holding capacity. • The horizontal filter plate and even thickness of cake, prevents the cake dropping as well as cracking, thus assuring better filtrate quality. • The Filtration area and cake holding capacity can be increased or decreased according to requirement.

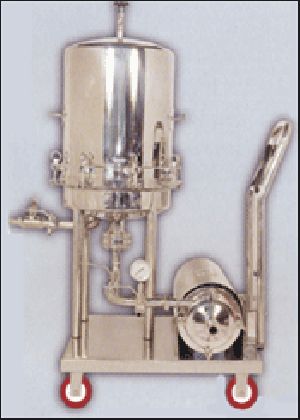

Zero Hold Up Filter Press

Get Price Quote

Zero Hold Up Filter Press that we offer is precisely manufactured keeping in mind the set industry standards. Our Zero Hold Up Filter Press is subjected to stringent quality tests prior to its final dispatch. We are counted among the top Manufacturers and Suppliers of Zero Hold Up Filter Press. WE are efficient enough to process retail as well as bulk orders for Zero Hold Up Filter Press even at short notice period. Details : Manufactured in Ss-304 / 55-3161 55-3161 Quality, Argon Arc Welded and Mirror Polished. Ss Jacket Can Be Provided for Hot Filtration. It is Generally Used to Obtain Crystal Clear Filtration By Filtration By Filtering Particles Up to 1 Micron Size. It Can Be Provided with Different Types of Pumps I.e. Gear Lobe Centrifugal Pump, Depending On the Viscosity of Liquid and Output, Which Can also Be Used for Liquid Transfer. T.E.F.C. Flame Proof Motors Can Be Provided. Provided with Pressure Gauge, Safety Valve, Bypass System, Sampler, Air Vent & Drain System. Can Be Manufactured as per Customer Design Requirement. Cake Formed Between the Plates Can Be Obtained if Required. and Also, It (cake) Can Be Dried Either By Compressed Air or By Inert Gas, Steam. Complete Unit is Mounted On Ss Trolley & Fitted with Ss Bracket, Pu. Bond Castor Wheels for Easy Movement. Scavenger Plate Arrangement to Remove all the Liquid.

Best Deals from Pressure Filter

Horizontal Filter Press

Get Price Quote

The filter cartridge assembly inside the shell consists of several horizontally arranged disc type filter plates with perforated supporting screens, filter media & interlocking cups. The entire assembly complete with pump & piping connection is mounted on a suitable S.S. Trolley.

SPARKLER TYPE FILTER PRESS

Get Price Quote

Standard flow type : the impure liquid to be filtered is fed to the filter shell by pump. It arrives on top of each plate through opening on the sides of plates. As liquid pressure increases, the filter media (paperfabric) holds back the impurities & allows the crystal clear filtrate to pass through the central channel (formed by interlocking cups) which takes the filtrate to the outlet of filter. This filter most commonly used to obtain clear liquid. However if required, the cake formed between the plates can be obtained. Filtration is continued until its rate becomes very slow due to increased cake resistance.

Frame Type Filter Press

Get Price Quote

We are offering frame type filter press. Indo german plate & frame type filter press is designed for filteration and clarification of pharmaceuticals, chemicals, food and bewerage industries.

Chemical Filter Press

Get Price Quote

Avail well designed Chemical Filter Press from G. P. Filtech Engineers. We are acknowledged among the leading Manufacturers and Suppliers of Chemical Filter Press. These Chemical Filter Presses are manufactured as per the international standards. The best raw material is used to manufacture these Chemical Filter Presses. Sizes Available 250mm x 250mm355mm x 355mm500mm x 500mm610mm x 610mm800mm x 800mm915mm x 915mm1000mm x 1000mm1200mm x 1200mm

Membrane Filter Holder

Get Price Quote

• Model Available : 142mm & 293mm Dia. • M.O.C.S.S 304 / 316 / 316L. • It is provided with Center and Non Sticky S.S. Perforated Sieve, Silicon ‘O’ Ring Detachable S.S. Stand and with Inlet Outlet Connection etc. • Option : Bubble Test Arrangement.

Filter Press Machine

150,000 Per Piece

1 Piece (MOQ)

Leaf Filter

Get Price Quote

Leaf Filter is designed from Stainless Steel Coarse mesh acting a main support & Hollander Mesh for filtering. Meshes are held together in a tubular leak proof frame by help Stainless Steel frame. Basic used in Chemical & Oil Industries.

vertical pressure leaf filters

Get Price Quote

A Vertical Pressure Leaf Filter consists of a hermetically sealed tank with vertical filter leaves mounted on a central manifold at the bottom Each filter leaf is made from 5 layers of wire mesh – 2 outer filtering layers and 3 inner support layers Vertical Pressure Leaf Filters are used for filtration of liquids with ~7% suspended solids: A Vertical Pressure Leaf Filter consists of a hermetically sealed tank with vertical filter leaves mounted on a central manifold at the bottom Each filter leaf is made from 5 layers of wire mesh – 2 outer filtering layers and 3 inner support layers Outer layers of fine wire mesh are selected depending on the application - these act as the primary filtering elements and eliminate the need for filter cloth Inner layers of coarser mesh support the outer layers and serve to collect and discharge the filtrate Filter cake is discharged from the bottom of the filter using a pneumatic vibrator to shake the leaves Cake discharge outlet is provided with a Butterfly valve that can be pneumatically controlled from a remote location, or with a wedge lock full opening valve with heel leaf Vertical Pressure Leaf Filters are self cleaning and simple to operate without need for repeated opening of the filter body The entire filtration cycle can be easily automated by using a PLC to switch between the priming, filtration, and cleaning steps at regularly timed intervals or based on pressure readings inside the filter Applications Major application of Pressure Leaf Filters is in the filtration of Catalysts, Carbon black, and Bleaching earth in Edible oil processing, Crude oil Bleaching and Post-bleaching, Hydrogenation, Winterisation, and Fractionation Applications in the chemical and process industry include Aluminates, Fatty Acids, Sulphur, Mining, Brine, Resins, Ni Catalyst, and Electrolytes MOC Filtering Mesh is manufactured from SS316L, while the inner meshes and collecting channels of the leaves are manufactured from SS304 The housing and support elements can be manufactured from Carbon Steel, SS304, Monel, Inconel, Carbon Steel, etc. based on customer specifications Filters can be provided special linings such as SS304/ SS316L for food grade processes, e.g. in Vegetable Oil refining

High Pressure Gas Filter

Get Price Quote

We are offering high pressure gas filter airmatic high pressure series - hpf service : compressed air & gases sizes: 6 mm to 15 mm (g 14", g38" & g12") flow: up to 60 scfm @ 40 kg cmâ²g airblast circuit breakers, oxygen filtration for breathing gas mixture, high pressure blow moulding of plastics, gas filtration for diving bells, starting air for diesel engines, filtration of natural gas, high pressure breathing air. Fertilizer, chemicals, petrochemicals, textile machines, machine tools, pneumatics, refineries.

nutch filters

Get Price Quote

316 Stainless Steel fabrication or other alloys including Hastelloy C-276C-22 optionally available. • For aqueous regia production nutsche filter available with halar or tefzal coating. • All Nutsche filters are as per ASME standard codes for full vacuum and pressures High purity design, various pharmaceutical grade finishes including electro-polishing, mirror, matt and dull finish. Optional jacketing for heating cooling or electric heaters. • Easy clamping of filter media • Optional coatings including Teflon. • Safety pressure relief valves or nitrogen purging nipple.

Baghouse Dust Collector

Get Price Quote

Manufactured from premium grade materials that are obtained from trusted vendors, our Baghouse Dust Collectors are in wide demand. These promise efficiency at reasonable and highly competitive rates. We have a reputation for supplying goods to our clients from different locations on time without any loss in quality or quantity. Contact our sales executives in person or over the phone if you require further details.

Membrane Syringe Filters

Get Price Quote

Agitated Nutsche Filter

Get Price Quote

We are offering agitated nutsche filter.anf with electromechanical drive capacity 200 ltrs. - 20,000 ltrs. diameter 500 mm - 4,000 mm internal design pressure full vacuum to 5 kgs/sq. Cm. jacket pressure : 6 kg/sq. Cm. (max) rpm's 12 - 20

Pressure Sand Filters

Get Price Quote

Pressure sand filters are designed for higher flow rates per unit cross section area. These filters are designed with backwash arrangement which is done with the assistance of air blower and pump. We have supplied these filters for steel plants and power plants for filtration of raw intake water at suction side.

Filter Press

Get Price Quote

The filter press is a solid liquid separation device using the principle of pressure feeding. It includes a series of filter plates and frames or recessed plates which are arranged alternately. The filter medium is provided in between the plates. A feeding pump is utilized to force the liquid through the medium leaving the solid trapped inside.

Membrane Filter Holder

Get Price Quote

It is made out of ss 316 L quality for filteration of sterile solutions. Complete with two silicon ‘O’ rings and support screen with non-sticking mirror polished bolts and wing nuts An air valve is also provided to remove inside air initially. Complete unit rests on suitable legs.It is available in 142mm & 293mm dia sizes SS 316 L Quality Membrane Filter Holder (GMP):- ss 316 L quality for filteration of sterile solutions. Complete with two silicon ‘O’ rings and support screen with non-sticking mirror polished bolts and wing nuts An air valve is also provided to remove inside air initially and available in 142mm & 293mm dia sizes

Pressure Sand Filter

Get Price Quote

Filter Press

Get Price Quote

Filters Pressused for filtering process in pharmaceuticals, coconut processing plants, milk dairies, distilleries, breweries etc. We supply a wide range of Filters and transfer pumps according to desired capacity that are made using high quality stainless steel. CGMP Zero Hold-Up / Sparkler Type Filter Press consist of Stainless Steel Shell & Top cover using bolts to give pressure tight enclosure. The filter cartridge assembly inside the shell consists of several horizontally arranged disc type filter plates with perforated supporting screens, filter media & interlocking cups. The entire assembly complete with pump & piping connection is mounted on a suitable S.S. Trolley. SALIENT FEATURES : • Available model 8", 14" , 18", 24" & 33". •Total access for fast cartridge removal and cleaning filter press machine • Centrifugal / Gear / Lobe pumps can be offered, which can also be used for liquid transfer • MOC SS 304/316/316L. • Complete filtration of the batch without any hold up due to reverse flow of liquid, making it cost efficient and time saving • In compliance with CGMP •Pressure gauge, safety valve & air vent provided to ensure safe operation