Pneumatic Filter Silencer Muffler

8 Per Piece

20 Piece (MOQ)

Our porous plastic Pneumatic Silencing Filters are a cost-effective and simple solution to reduce the noise level of vented air and prevent unwanted discharge of contaminants from exiting pneumatic devices / machines. Our porous plastic filter elements are low cost, light weight and offer high chemical resistance with higher noise reduction compared to alternate materials.The strategic design of our porous plastic Pneumatic Silencers assists in reducing the decibel level of air being discharged during pneumatic processes. The air coming out of the exhaust port, during pneumatic processes, could potentially produce unwanted noise which may adversely affect the surrounding environment, as well as be harmful to workers in the vicinity. Our filter elements improve the working environment by reducing the noise level of this discharged air.In addition, our porous plastic silencers prevent undesirable discharges to escape into the atmosphere; further preventing an adverse impact at the work place.

Pressure Sand Filter

Get Price Quote

Our company is eminent Pressure Sand Filter Manufacturer India. We are offering assorted range of the best in class Pressure Sand Filters that consists of a multiple layer of sand with a variety in size and specific gravity. These Filters are designed to remove turbidity and suspended particles present in the feed water with minimum pressure drop. These Filters are custom designed to suit the process requirement. Our offered Pressure Sand Filters are appreciated for their efficiency, corrosion resistant, durability, easy operation and easy maintenance, thus makes us as ultimate choice as Pressure Sand Filters manufacturers in India to our esteemed clientele. This offered Pressure Sand Filter are manufactured with state of art facility under the supervision of experts. Quality control is our top priority and ensures that all our offered Pressure Sand Filters passed laid quality checking procedures. We are offering finest quality Pressure Sand Filter at competitive prices available in the market.

Best Deals from Pressure Filter

33 Inch Zero Hold Up Sparkler Filter Press

160,000 - 500,000 Per Piece

1 Piece (MOQ)

CENTRAL FEEDING OF UNFILTERED LIQUID ENSURES : SINGLE PASS CLEAR FILTERATION. FULL BATCH RECOVERY OF THE FILTERATE. NO SCAVENGING OF THE FILTERATE. COMPLETE CAKE RETAINS ON THE PLATE. UNIFORM DISTRIBUTION OF CAKE ON EACH PLATE. REDUCE THE COST OF TREATEMENT OF CATALYST, TOXIC CHEMICALS. LESS EXPOSURE TO THE OPERATING PERSON. NO CONTAMINATION OF THE INTERNAL SURFACE OF THE SHELL.

Pressure Sand Filter

24,997 Per Piece

1 Piece (MOQ)

Agitated Nutsche Filters

Get Price Quote

Determined to present the utmost quality, we are involved in offering Agitated Nutsche Filters. Our capable staff keeps manufacturing process under stringent guidance to make certain our quality is in fulfillment with different quality grades set by industry. Hence, our customers can be certain of the excellence on offer. We offer a range of several designs and sizes. At their ease, customers can get them delivered. Details : Pressure Nutsches can handle a variety of flow rates and solids loading that can be discharged in dry or slurried form. They can be designed for pressures up to 75psi or full vacuum. Pressure nutsches are ideal for lab, pilot or batch applications and for easily filtered material such as carbon particles, salts and other products where a cake thickness of 6 inches or more can be attained.Pressure Nutsche Applications : Ideal for piloting of new or modified batch operation and/or processes requiring recovery of the cake. The Pressure Nutsche is excellent for lab, pilot or batch applications where cake thickness of 6” and above is achievable.

Membrane Filter Holder

4,520 - 9,020 Per Packet

100 per packet (MOQ)

Pressure Leaf Filter

Get Price Quote

1 Piece (MOQ)

Zero Hold Up Sparkler Filter Press

350,000 - 1,200,000 Per Piece

1 Piece (MOQ)

Description: Sparkler Filter Press is a filtration machine used to filter liquid in pharmaceutical, chemical, beverage, and other industries. Filter Press works on the principle of pressure feeding. Features: Due to the reverse flow of liquid, there is zero hold up in the filter press that leads to complete filtration of the batch. A backwash can provide a facility for continuous operations. No scavenger arrangement is required. The cake, filter aid & solids remain enclosed, allowing filtration of toxic, hazardous & explosive liquids. The top dome structure ensures fast & easy removal of cartridge assembly & cleaning of cake. We can increase the number of plates as per toxic levels of input or filtration requirements.

Pressure Sand Filter

Get Price Quote

Pressure sand filter is used for the removal of suspended solids & turbidity. The pressure sand filter is extremely robust method of removing suspended solids from water. The filtration medium comprises of multiple layers of sand having different sizes. As per the needs of our customers, we can offer sand filters in various sizes and material apart from hand operated or fully automatically operated.HOW IT WORKS?Raw water is passed through sand filter at a pressure of 2 - 3.5 kg / cm2.This reduces the suspended solids that are present in the raw water. This filter has the ability to remove up to 30 to 50 micron of suspended solids to less than 5 ppm It is mandatory to wash the filter daily with raw water for 20 to 30 minutes For the filtration of partials below 30 to 50 micron, the cartridge filter is used They are manufactured in mild steel, stainless steel, FRP, MS/RL etc.

Filter Press Machine

150,000 Per Piece

1 Piece (MOQ)

Nutsche Filter

Get Price Quote

Our company is counted among the reputed Manufacturers and Suppliers of Nutsche Filter. The Filter offered by us is known for its supreme quality, high efficiency and reliable performance. We make available FRP / PP / PVC / HDPE nutsche type filters for corrosive chemicals. Besides, the unbeatable quality of Nutsche Filter has not only made us a preferable choice in the market but has enabled us to earn the faith of the customer. Ideal For : Corrosive chemical filtration Availability : FRP PVC PP HDPE

Agitated Nutsche Filters

Get Price Quote

Associated with a diligent professionals and smart packaging facility, we are capable to undertake standard as well as tailored packaging requirements of the clients. Our products are subjected to the payment terms & conditions of our company. Patrons are provided with the terms & conditions, and can make purchases with a payment method best suited for them. Features : Quality tested Lightweight

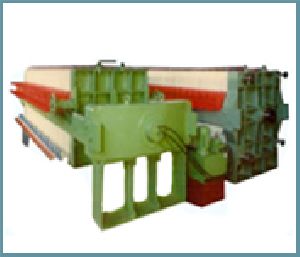

Recess Type Filter Press

Get Price Quote

1 Pieces (MOQ)

TRIMURTI FILTER PRESSES are well known for their up-to-date design, sturdy construction, and easy operation. These are largely used by chemical and Sugar factories and especially by OIL MILLING INDUSTRY for producing a first-class filtered oil and also saves an enormous loss of time and space required for the oil to settle down in tanks. These are prepared in two types :(1) Recessed Types(2) Flush Plate and Distance Frame Type. RECESSED TYPE The plates in this type are recessed so that when two plates are closed together, a chamber is formed. Each plate has a center feed hole and the faces are cast with pyramid type indentations to increase the filtering area. Filter cloth is placed on each plate and fastened back to the plate with hollow clips. When the press is closed, the cloth forms a tight joint between the machined edges of the plates. The liquid to be filtered is pumped into the press to fill up the chamber formed by the plates. The liquid is then forced out through the cloth, to the passage at the base of the plate, and hence to a trough through bib cocks. FLUSH PLATE AND DISTANCE FRAME TYPE In this type, the machined edges are almost at level with the indentation surface. A separate form is used between them to form the chamber. The cloths are not fastened in any way to the plate, but only hang over the frame and nipped between the edges of the plates and distance frames, when these are closed together. The filter cloth is thus easily renewed for cleaning. The thickness of the frame determines the depth of the chambers. The type is recommended for filtering oils with the use of filter aids, such as fullers earth, Kieselguhr, or activated carbon. STANDARD EQUIPMENT These are supplied with suitable belt-driven on motorized pumps. Standard equipment also includes the necessary safety valve air vessel, pressure gauge, out, et cocks trough, etc. Filter cloth bags are supplied at extra cost.

Bag Filter

5,300 - 5,500 Per piece

1 Piece (MOQ)

A bag filter is designed to remove various types of contaminants from water so that it is safe for usageThis system is used in the filtration process for boiler water, rinse water, cooling water, process baths and circulation water of heating plantsSome of the many contaminants that it can remove include anything ranging from sediments, to certain types of solids and even liquids present in waterThere are bag filters for specific types of industries and it is a versatile, cost effective means of filtering lots of water in a short period of time.It is preferred in places that demand a filtration system with high capacity and flow rateIt can be easily replaced by another filter as and when requiredIt is one of the most popular means of water filtrationThe Aqua Systems Technology bag filter is made from unique material so that it is strong and does not allow pollutants or other contaminants to get awayAs water enters through the bag filter, it passes through small permeable pores, sizes of which can be 1 to 200 micronsAll dirt and chemicals in the water is trapped in the bag, while clean water comes outBig bag filter systems have the capacity to hold more than 500 m3/h of waterA team of qualified and experienced TECHNICIAN is always on it’s toes to provide any technical services to the customers round the clockThis ensures the utmost satisfaction of each customer, therefore an unbeaten faith of their in ASTA vision to make water treatment as the most sophisticated, scientific and competitive business, AST is thriving to excelWith matchless quality of products, committed delivery schedule, prompt services and customer friendly attitude, AST has achieved the exponential growth in short span of timePursuing highest standards and passing through stringent stage wise quality checks; AST produces a product that can optimize customer’s productionProducts of high quality standards.Aqua Systems Technology is one of the best Bag Filter manufacturer, Bag Filter exporter, Bag Filter supplier in mumbai IndiaWe are provide this Bag Filter product in all over countriesIf you have this Bag Filter product please visit here or quote Now.We are engaged in manufacturing premium-quality Bag Filter They are effective in removing solid particulate from liquids where large volumes of contamination are present or for filtering high viscosity fluidsThey are manufactured using high dirt holding media that provides consistent particle retentionTheir long life leads to less purchase cost and minimal downtimeThe overall filtration cost is also low as compared to cartridge filtersOur filter bags have the lowest standard deviation amongst other filtersThey are reasonably priced.We Offer full range of filter bags to meet your exactly needsThey are effective in removing solid particulate from liquids where large volumes of contamination are present or where high viscosity fluids must be filteredThe Bag Filters are fabricated using high dirt holding media that provides consistent particle retentionLonger life reduces purchase cost & down times due to change outs, and disposal costsThus it reduces overall filtration cost compared to cartridge filtersOur Filter Bags have the lowest standard deviation of any other filter which means users achieve more consistent results from batch to batchEqually important, this product presents the ultimate value in high purity filtration.Features and Benefits : High performance Filtration rating from 1 to 100 Micron Viscous fluid capability High flow rates Low pressure drop Broad chemical compatibility Positive sealing arrangement with choice of materials High dirt holding capacity Easy maintenance

Pre Seasoned Cast Iron Paniyaram

Get Price Quote

100 Piece (MOQ)

Zero Hold Up Filter Press

90,000 Per Piece

We are instrumental in providing our clients a comprehensive range of excellent quality Zero Holdup Filter Press Manufacturer In India. Our complete range is designed with top quality of material in accordance with the market norms. Product range Alpro Equipments is a specialty of manufacturing and suppliers all kind of range Zero Holdup Filter Press. Alpro equipments has been actively involved in Zero Holdup Filter Press Manufacturer, which are widely used in Pharma, bulk drugs, distilleries, beverages & varies industries. we are supplier, export and zero holdup filter press manufacturer in india. our product are perform high with low maintance, alpro equipments team are expert to design and fabricate of best Zero Holdup Filter Press with industrial standard. Features of zero hold up filter press: Low noise operation. High output results. Consume less power. Description: Zero hold up Horizontal plate closed pressure filter that meets all the demands for a filtration which would discharge solid free filtrate. Design of filter press is according to cGMP & FDA approval. Other Details: Components are argon arc welded & polished to mirror finish SS jacket can be provided for hot filtration. (Optional) Provides crystal clear filtration by filtering particles up to 1 micron size. No Scavenger arrangement is required No liquid between the tank & the cartridge Top dome structure ensures fast & easy removal of cartridge assembly & cleaning of cake Uniform filter aids & cake distribution SS pump mounted on SS trolley with heavy duty trust ball bearing caster wheels for easy movement Provided with different types of pumps depending on the viscosity of liquid & output i.e. Centrifugal pump, Gear Pump, Lobe Pump, Roto Pump Etc Provided with bypass system, safety valve & sample collecting device No contamination of internal surface of the shell Horizontal plate Zero Hold Up filter press is constructed in such a manner that it prevents evaporation,Oxidation, Leakage & Fumes escaping from product Plates are available in two sizes: Deep plate for higher percentage of caking holding capacity & shallow plate for lesser percentage of cake holding capacity Filter plate & thickness of cake prevents the cake dropping as well as cracking, thus assuring better filtrate quality According to requirement filtration area & cake holding capacity can be increased or decreased

Nutsche Filter

Get Price Quote

Nutsche Filter is a filtration technique used for waste water treatment. It is used because certain solvent evaporation causes safety and environmental hazards. Here filtration is carried under vacuum or pressure closed vessel, even solids can be discharged straightaway into drier. Some of our manufactured Nutsche Filters are installed at • Enviro Analysts and Engineers P Ltd. – Mumbai • Vijay Gul Production. – Jalna

Manual Filter Press Spares

Get Price Quote

Stainless Steel Bag Filter Housings

10,000 - 45,000 Per

1 Piece (MOQ)

We are one of leading manufacturers and supplier of SS Filter Housing SS Bag Filter Housing in Mumbai, India.Features: Custom design services Choice of basket filter elements Single cylinder design Double cylinder design Multi-cylinder design Pleated element design available for low-pressure drop & high dirt hold Large-area, heavy – duty baskets Low-pressure drops Easy to clean Liquid displacers for easier servicing Normally designed for free flow area through screen, 4 – 6 times pipe flow area Covers are O-ring sealed All housings made from SS 316 L, SS 316 & SS304 are mirror polished to resist adhesion of dirt and scale Carbon steel housing are painted coated externally & internally epoxy coated Option of backwashing ASME code stamp available High-pressure rating design available Duplex / Triplex & Jacketed units available High temperature & high-pressure design are available Housing is permanently piped

polypropylene filter press

Get Price Quote

Our company is well versed with online as well as traditional payment methods. As per requirements of patrons, we can sign an agreement for payment with suitable terms and conditions. Our main concern is to deliver top-of-the-line quality products and for this, we check the entire lot on several quality parameters. Features: Energy efficient User-friendly High productivity

Pressure Filters

4,800 - 4,999 Per Piece

Pp Filter Press

Get Price Quote

Agitated Pressure Nutsche Filter

Get Price Quote

We are offering agitated pressure nutsche filter. The agitated pressure nutsche filters offered by us has the following features : * filter vessel designed as per is asme standards * variety of materials * jackets limpet coils * the scraper assembly and discharge port can be provided with hydraulic actuation with electrical controls as an option. * cgmp finish optional

Membrane Filters

Get Price Quote

Our company holds expertise in supplying premium Membrane Filters. Membrane filters or “membranes” are microporous plastic films with specific pore size ratings. Also known as screen, sieve or microporous filters, membranes retain particles or microorganisms larger than their pore size primarily by surface capture. Some particles that are smaller than the stated pore size may be retained by other mechanisms.

Membrane Filter

Get Price Quote

* Bubble test arrangement can be provided * Filter Support Screen With Teflon / Pharmaceutical Silicon Ring * Detachable Stand

vertical pressure leaf filters

Get Price Quote

A Vertical Pressure Leaf Filter consists of a hermetically sealed tank with vertical filter leaves mounted on a central manifold at the bottom Each filter leaf is made from 5 layers of wire mesh – 2 outer filtering layers and 3 inner support layers Vertical Pressure Leaf Filters are used for filtration of liquids with ~7% suspended solids: A Vertical Pressure Leaf Filter consists of a hermetically sealed tank with vertical filter leaves mounted on a central manifold at the bottom Each filter leaf is made from 5 layers of wire mesh – 2 outer filtering layers and 3 inner support layers Outer layers of fine wire mesh are selected depending on the application - these act as the primary filtering elements and eliminate the need for filter cloth Inner layers of coarser mesh support the outer layers and serve to collect and discharge the filtrate Filter cake is discharged from the bottom of the filter using a pneumatic vibrator to shake the leaves Cake discharge outlet is provided with a Butterfly valve that can be pneumatically controlled from a remote location, or with a wedge lock full opening valve with heel leaf Vertical Pressure Leaf Filters are self cleaning and simple to operate without need for repeated opening of the filter body The entire filtration cycle can be easily automated by using a PLC to switch between the priming, filtration, and cleaning steps at regularly timed intervals or based on pressure readings inside the filter Applications Major application of Pressure Leaf Filters is in the filtration of Catalysts, Carbon black, and Bleaching earth in Edible oil processing, Crude oil Bleaching and Post-bleaching, Hydrogenation, Winterisation, and Fractionation Applications in the chemical and process industry include Aluminates, Fatty Acids, Sulphur, Mining, Brine, Resins, Ni Catalyst, and Electrolytes MOC Filtering Mesh is manufactured from SS316L, while the inner meshes and collecting channels of the leaves are manufactured from SS304 The housing and support elements can be manufactured from Carbon Steel, SS304, Monel, Inconel, Carbon Steel, etc. based on customer specifications Filters can be provided special linings such as SS304/ SS316L for food grade processes, e.g. in Vegetable Oil refining

Bag Filter

Get Price Quote

We offer wide range of Bag Filter Designed to handle heavy dust loads, a Dust Collector system consists of a blower, dust filter, a filter-cleaning system and a dust receptacle or dust removal system. It is distinguished from air cleaners which use disposable filters to remove dust. The dust-laden air enters the Bag Filter. The dust / powder separates inside the bag air filter chamber. The air is uniformly distributed avoiding channeling while the powder is separated. Initially a coat of material forms on the bags. Subsequently, the coat acts as the filtering medium. The dust is accumulated on filter elements while the air passes through the filter bags from outside to inside. The accumulated powder is dislodged from the bags by reverse pulse jet air intermittently. The dislodged powder falls on bottom cone and is discharged through powder discharge valves. The dust free air is sucked by induced draft fan and is exhausted to atmosphere.

Nutsche Filter

Get Price Quote

Leading Manufacturer & Supplier of Nutsche Filter.

Zero Hold Up Filter Press

Get Price Quote

Zero Hold Up Filter Press that we offer is precisely manufactured keeping in mind the set industry standards. Our Zero Hold Up Filter Press is subjected to stringent quality tests prior to its final dispatch. We are counted among the top Manufacturers and Suppliers of Zero Hold Up Filter Press. WE are efficient enough to process retail as well as bulk orders for Zero Hold Up Filter Press even at short notice period. Details : Manufactured in Ss-304 / 55-3161 55-3161 Quality, Argon Arc Welded and Mirror Polished. Ss Jacket Can Be Provided for Hot Filtration. It is Generally Used to Obtain Crystal Clear Filtration By Filtration By Filtering Particles Up to 1 Micron Size. It Can Be Provided with Different Types of Pumps I.e. Gear Lobe Centrifugal Pump, Depending On the Viscosity of Liquid and Output, Which Can also Be Used for Liquid Transfer. T.E.F.C. Flame Proof Motors Can Be Provided. Provided with Pressure Gauge, Safety Valve, Bypass System, Sampler, Air Vent & Drain System. Can Be Manufactured as per Customer Design Requirement. Cake Formed Between the Plates Can Be Obtained if Required. and Also, It (cake) Can Be Dried Either By Compressed Air or By Inert Gas, Steam. Complete Unit is Mounted On Ss Trolley & Fitted with Ss Bracket, Pu. Bond Castor Wheels for Easy Movement. Scavenger Plate Arrangement to Remove all the Liquid.

Membrane Filter Holder

Get Price Quote

Smart logistics network, speedy services and reliable transit facilities have enabled us to furnish safe and time bound deliveries. Safety of the products is the prime concern of the organization. Thus, we store the entire lot in a capacious and well-structured warehouse till the delivery of the orders.