500 L Stainless Steel Liquid Mixing Tank

170,000 Per Piece

1 Piece (MOQ)

Vent Filter Vessel

4,855 Per Piece

Best Deals from Pressure Vessels

continuous reactor

Get Price Quote

1 Piece(s) (MOQ)

Continuous Reactor is extensively used in the chemical industry in case of conducting exothermic or explosive reactions. Our Continuous Reactor is known for providing high output and for balancing the process of mixing and heat transfer. Continuous Reactor that we offer also ensures feasible radial mixing and is also used for mixing high viscous liquids. Our Continuous Reactor is ideal for heat transfer, reaction engineering or engineering. Main Characteristics : Short residence time Constant heat transfer Smooth appearance Quality design Unconventional technique We Have Cover Following Markets : USA : New-Jersey, Montana, New-Mexico, South-Dakota, Florida, Alaska-Nevada, Texas,etc. Middle East : Yemen, Israel, Saudi Jordan, Kuwait, Cyprus, Oman, Syria, Egypt, Arabia,etc. Europe : Austria, Malta, Sweden, Poland, Monaco, Andorra, Italy, Finland, Croatia, Albania,etc. Others : Pakistan, Maldives, Nepal, Myanmar, China, Bhutan, Bangladesh,etc. Indian Areas : Mumbai, Andhra-Pradesh, Bihar, Delhi, Assam, Haryana, Orissa, Madhya-Pradesh, Himachal-Pradesh, West-Bengal, Punjab, Rajasthan, Gujarat, Karnataka,etc.

Order plug flow reactor

Get Price Quote

In the chemical industry whenever an exothermic or explosive reaction is needed to be carried out through the conventional way then in that case Their manufactured Plug Flow Reactor is widely utilized. They also ensure the safety of the equipments beside the uniform heat transfer. Our manufactured compact reactor possesses all the characteristics of heat transfer, static mixing and reaction engineering.

Steam Jacketed Vessel

Get Price Quote

1 Piece(s) (MOQ)

We are offering steam jacketed vessel. Make solid and liquid preparations in bulk with equal ease. Extra heavy double walled stainless steel steam vessel perfectly designed. Low energy cost, high performance and without burning or scorching, most hygienically

Pressure Feed Tank

Get Price Quote

Pilot Pressure Feed Tanks are equipped with easy to operate air regulators (to set the desired fluid outlet pressure), safety pressure relief valves and Manual, Rotary or Oscillating agitation types to provide the best quality agitation. Pilot offers a range of Pressure Feed Tanks for varying needs. Technical Data : Standard containers are available in sizes : 5, 10, 20 and 40 Litres Maximum Air Inlet Pressure : 60psi (4 bar) Maximum Working fluid Pressure (For HVLP or low-pressure, fine-adjustment applications) High-Pressure Regulated Tank : 60psi (4 bar)

Process Reactor

Get Price Quote

Storage Vessel

Get Price Quote

Pressure Vessels

Get Price Quote

Being a customer-oriented firm, we make available numerous modes of payment and assure them for confidentiality of transaction. Also, our payment modes are authorized. We have maintained our high standards in the market by delivering only high-quality products and this is done by using quality raw materials obtained.

PP.FRP Tank

Get Price Quote

We design, manufacture and install PP.FRP Tank. These are fabricated out of industrial plastics like PP, FRP, PVC/FRP, PP/FRP, PVDF/FRP, FRB, and FRVE etc of various shapes & sizes as per client's operational requirements.

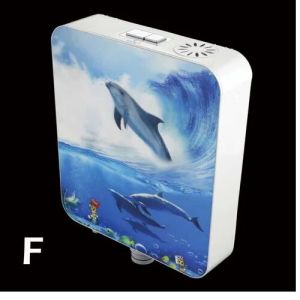

Flush Tank

Get Price Quote

Flush tanks and other sanitary ware products manufactured by Orient Ceramic includes different kinds of flush tanks like Dual Flush Tank, High Level Side Handle Flush Tank and Low Level Flush Tank.

High Pressure SS Vessel

48,000 Per Units

Wire Mesh Packing

Get Price Quote

KEVIN ME-II Wire Mesh Packing has enhanced self-wetting characteristics; as the fiber is woven from fine diameter wires. The packing element consists of parallel-perforated corrugated sheets of wire mesh. These packings are particularly suited in separations that require a large number of separation stages, which typically operate under high vacuum and therefore low liquid loads. The capillary action of the wire mesh ensures complete surface wetting when complemented with high efficiency internals. KEVIN ME-II Wire Mesh Packing is available in following two types:

Dish End

Get Price Quote

We offer a comprehensive variety of Dish End at ROYAL ENGINEERING. We can supply dish end from 21.3 to 14000mm with thickness from 2 to 300 mm in all types of materials including clad plates. The prices offered by us are quite reasonable and we guarantee apex quality of the Dish End. Applications : Industries chemical and cement industryPower plantsRolling mills Range : Tori spherical headSemi ellipsoidal headEllipsoidal headStandard-type/Flat dished headHemispherical headConvex discConeCrown & petal heads

Pressure Feed Tanks

Get Price Quote

We are offering pressure feed tanks, pilot pressure feed tanks are equipped with easy to operate air regulators (to set the desired fluid outlet pressure), safety pressure relief valves and manual, rotary or oscillating agitation types to provide the best quality agitation. Pilot offers a range of pressure feed tanks for varying needs.

Alcohol Storage Vessel

Get Price Quote

Machine Applications Storage Of Alcohol Storage Of Low Viscosity Liquids Storage Of Medium Viscosity Liquids Storage Of Water

Pressure Vessels

Get Price Quote

The term pressure vessel refers to vessels operating above the atmospheric pressure, or subject to external pressure. A pressure vessel is a vessel containing a fluid which has a pressure that is higher than outside.

Pressure Vessels

Get Price Quote

PRESSURE VESSELS IN A WIDE RANGE CAPACITIES AND PRESSURES DC constructs stirred reactors and pressure vessels from most machinable alloys. Capacities range from 50 cc to 500 gallons (2 m3). Agitated reactor design pressures range from full vacuum to 150,000 psig (10,300 barg). Temperatures range from -400 °F to 2,500 °F ( -200 °C to 1,400 °C). Each stirred reactor is a complete system. This includes the reactor vessel, supporting stand, agitation assembly (magnetic stirrer, drive motor, belt, belt guard, impeller and digital tachometer), multiple process connections, drain, sample tube, temperature sensor, cooling coil and rupture disc assembly. Heating system and controls are optional. We offer a complete skid mounted stirred reactor system complete with product loading, feed, reaction and receiving modules, mass balance and product analysis. We also offer a variety of controls from simple manual controls to advanced PC-based SCADA and DCS. Please refer to our pilot plant section for additional information. Interested in a quote on a PDC stirred reactor? Please use our Stirred Reactor and Pressure Vessel Selection Guide to help you specify your stirred reactor or pressure vessel. INSTRUMENTATION AND CONTROLS PDC Machines supplies advanced instrumentation and control packages providing precise data acquisition to automatically record and manipulate multiple process parameters such as data logging, alarm monitoring, real-time and historical trending. These features are essential for predictable and repeatable process performance and scale-up. Our control packages are designed to be easily re-configured for flexibility and to adapt to developments in new technology. We combine the talents of process consultants, instrumentation and controls experts from various sources including Honeywell, Allen Bradley, Rosemont, Fisher, Siemens, Wonderware®, Intellution®, Cimplicity®, Think & Do®, LabVIEW®, and RSView® to name just a few. OUR CLIENTS Our clients include: • Air Products and Chemicals • Chevron Phillips Chemical Co • Akzo Nobel Chemicals • Celanese Chemicals • Bayer Corp • Cook Composites & Polymers • he Dow Chemical Co • E.I. Du Pont • Engelhard Corp • ExxonMobil Chemical Co • General Electric Corporate R&D • Omnova Solutions • International Specialty Products • Penford Products Co • Rohm & Haas • PQ Corp • Sartomar Co • Witco Chemical Corp. • Saudi Arabia Basic Industries (SABIC) • W.L. Gore & Associates

Flush Tank

1,850 Per Piece

1 Piece (MOQ)

Sanitary Filter Vessels

Get Price Quote

Pressure Vessels

Get Price Quote

Made out of 16 gauges AISI 316 complete with ring cover, wing nuts and neoprene gasket. Bent out-let nozzle will be fitted with S. S. Pipe to draw out all the fluid from the vessel. Inlet nozzle for allowing pressurized air. This vessels are tested at 4 bar pressure , conical in shape at top.

Process Reactor

50,000 Per Units

Offshore Chemical Tank

Get Price Quote

1 Piece (MOQ)

Bitumen Storage Tank

Get Price Quote

We are offering bitumen storage tank, fabricated from m.s plates with insulation and heating coils of various sizecapacity as per customers requirement and specifications.

Pressure Vessel

Get Price Quote

1 Set(s) (MOQ)

Pressure vessels are manufactured in various materials like pp + frp / pvc + frp / pvdf + frp / frp / frv etc. pressure vessels are designed as per client’s requirement depending upon capacity required / temperature of fluids to be stored , type of fluid / density /pressure / vacuum expected in vessel. these vessels are manufactured normally with conical top and bottom or dish ends.

Septic Tanks

Get Price Quote

pp frp chemical storage tanks

Get Price Quote

pp frp chemical storage tanks, Fiber Glass Pultruded Grating

FRP Storage Tank

10,000 - 120,000 Per piece

FRP Storage Tank, Heavy Duty Industrial Blower, Scrubber System

High Pressure Vessels

Get Price Quote

We manufacture and supply High Pressure Vessels that can operate efficiently even when power supply is low. High grade materials are employed to ensure corrosion free and reliable products. Our vessels are amongst the best that are available and can be availed from us at affordable and reasonably nominal rates. They come with a compact design and perfect finish making them popular among our clients. Description: A pressure vessel is a closed container designed to hold gases or liquids at a pressure different from the ambient pressure Pressure vessels are used in a variety of applications in both industry and the private sector They appear in these sectors as industrial compressed air receivers and domestic hot water storage tanks Other examples of pressure vessels are: mining or oil refineries and petrochemical plants, nuclear reactor vessel, and storage vessels for liquefied gases such as ammonia, chlorine, propane, butane and LPG.

Stainless Steel Pressure Vessels

Get Price Quote

With vast industrial experience we are engaged in offering a comprehensive range of SS Pressure Vessel. These are available in market in various sizes as per the requirements of our clients. Along with this, the offered range is developed using superior grade stainless steel, procured from certified vendors of market. These are highly appreciated among our clients for their long service life and broad chemical compatibility. Moreover, these have smooth finishing and are resistant to corrosion.