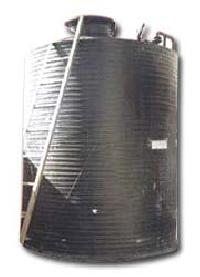

hdpe Chemical Storage Tank

Get Price Quote

Avail from us, Spiral PP/HDPE Chemical Storage Tanks that are made out of HDPE/P.P. The Spiral PP/HDPE Chemical Storage Tank is meant for storage of highly corrosive chemicals at high temperature and for capacities upto 50,000 litres. Range Vertical Profile TankHorizontal Profile TankRectangular Profile TankConical Bottom Profile Tank Salient Features H.D.P.E./P.P. Sleeves irrect by sprial wind processionResistant high temperaturesHigher resistance against chemical and corrosion & toxic elementsExtremely light in weight, so that easy to move & installResistance to abrasionResistance to degradation and no electrolyticFlexibilityWith fitting like flanged inlets & outlet float level indicator manHole and its cover

Stainless Steel Tank

1,000 - 6,000 Per Piece

10 Piece (MOQ)

Best Deals from Pressure Vessels

Puf Sandwich Panel

120 Per Square Feet

2000 Square Feet (MOQ)

DUPLEX REACTORS

Get Price Quote

These are current limiting reactors except that such reactors provide low reactance under normal conditions and a high reactance under fault conditions. The reactor consists of two halves, wound in opposite direction to serve the above application.

Pressure Vessel

Get Price Quote

We manufacture pressure vessels using metals with high tensile strength. The buyers can avail the vessels in varying capacities, ranging up to 20000 Liters, at affordable prices.

Structured Packings

2,000 - 300,000 Per Number

10 Nos (MOQ)

Heavy Duty Packaging Loading Capacity 10mt,

Biodigester septic tanks

Get Price Quote

sludge blanket build ups in aquaculture tank

Get Price Quote

Pressure Feed Container

11,500 Per Piece

Pressure Vessel

Get Price Quote

Precisely designed in adherence with all defined industry standards of quality, we offer long service life Pressure Vessel. Known for their high pressure bearing capacity, we Manufacture, Export and Supply pressure vessels for air and gas systems. Our quality team makes sure that Pressure Vessel has robust structure and anti-corrosive nature. With our wide distribution network we make sure that all orders are delivered in the stipulated time frame. For competitive prices, contact us.

Limpet Coil Reactor

Get Price Quote

Stainless Steel Liquid Manufacturing Vessel

Get Price Quote

Jacketed Pressure Vessel

Get Price Quote

We are main supplier of this product.

Steel Dished End

Get Price Quote

We are a Mumbai based reliable Manufacturer and Supplier of Steel Dished End. The Steel Dished End, which we offer, is made from quality stainless steel and mild steel. Steel Dished End is mostly used in Pressure Vessels industry as a top and bottom parts of the vessel. Highlights Customized solution DurableEnsured high performanceHigh quality materials used Material : Stainless steel & Mild Steel Application : Dished ends are mostly used in storage or pressure vessels industry as a top and bottom parts of the vessel.

Insulated vessel

225,000 Per Piece

SS316 total Capacity Limpeted Reactor

Get Price Quote

67 KL Total Capacity SS316 Limpeted Reactor 2 Pitched Blades. One Ruston Turbine with Bottom Bush Arrangement Flow-Serve make single Dry Mechanical Seal, with Internal Rigid Couplin. SS304 Lantern Stool. Inline Helical Nord make Gear Box and Compton make FLP Motor with internal and external Polishing resting on Skirt Support.

S S Reactor

Get Price Quote

Pressure Vessel

Get Price Quote

Capacity available 5 Ltrsto 500 Ltrs Safety valve / pressure gauge provided. Test pressure 5Kgs/cm. MOC SS316/316L

Water, or Liquid, in bladder type Surge Tank

Get Price Quote

The air charge is contained within the tank, whilst the liquid from the main flows into and out of the bladder. Like the air in bladder design, the liquid does not come into contact with the tank walls nor the air charge, so again, the air charge cannot be absorbed by the pumped liquid and so air losses due to absorption are minimal. The pumped liquid from the main flows into and out of the bladder and will not come into contact with the tank walls, again compatible materials must be selected. As for the air in bladder design, the bladder is often made from a highly elastic rubber, such as butyl rubber, and may be sized to expand to fit the entire vessel. For this design the whole tank is pre-charged at installation with a pre-determined pressure to give the correct operating level in the tank when the unit is connected to the main and at the operating pressure. Again, there must be an anti extrusion plate fixed at the outlet from the vessel to prevent the bladder from being drawn into the main at low pressures and like the air in bladder design, the anti-extrusion plate and inlet size must be selected so that they do not impose a restriction on the flow into and out of the vessel. Each bladder vessel comes with these standard features: Safety relief valve Pressure gauge Air fill valve Drain connection Internal membrane (bladder) Any of our standard bladder vessels may be fitted with the following optional features: Leak detection system Level gauge Level transmitter Pressure transmitter Drain valve Flo-Dyne bladder vessels are pressure vessels and as standard may be manufactured in ordinary carbon steel, low temperature carbon steel or 304/316 stainless steel to the requirements of the pressure vessel code of your choice. Typically this will be ASME VIII or PD5500, however we can also manufacture to IBR or your local requirement. We will CE mark the equipment if it is to be used within the European Union, if the equipment is to be used elsewhere we will apply a CE mark where requested if possible.

Pressure Vessels

Get Price Quote

CBL Pressure Vessels are widely recognized for impeccable quality and infallible reliability in design as well as manufacturing.