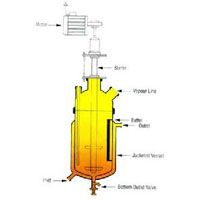

Chemical Process Reactors

Get Price Quote

Chemical Process Reactors are vessels designed to contain chemical reactions. One example is a pressure reactor. The design of a chemical reactor deals with multiple aspects of chemical engineering. Chemical engineers design reactors to maximize net present value for the given reaction. Designers ensure that the reaction proceeds with the highest efficiency towards the desired output product, producing the highest yield of product while requiring the least amount of money to purchase and operate. Normal operating expenses include energy input, energy removal, raw material costs, labor, etc. Type of Reactor we offerStirred reactorLimpet coil reactor Jacketed & Non jacketed reactors Inner coiled reactorsSolid thick walled reactors Our Reactor are fabricated from exotic material like, Titanium, Tantalum, Zirconium, Nickel, Monel, Inconel, Duplex & Super Duplex and Special grades of Stainless Steel

process reactors

Get Price Quote

1 Piece (MOQ)

Uses/Applications : Used in solvent process and fusion process for making Alkyd, UF, MF and Phenolic Resins Widely used in various industries like chemical, food & beverage and others Features : Easy and safe operations Study construction Leak proof Longer service life Easy installation Excellent surface finish

Best Deals from Process Reactors

static mixer reactor

Get Price Quote

Static Mixer Reactor is extensively used in all types of reactions whether it is explosive or exothermic. Our Static Mixer Reactor is also utilized in such cases where a constant heat transfer is required. The structure of our Static Mixer Reactor is specifically designed in such a way in order to make radial mixing feasible. It is also suitable for the processes of mixing viscous fluids. Our Static Mixer Reactor is immensely appreciated for features like heat transfer, static mixing, and reaction engineering. We provide Static Mixer Reactor in all sizes and ranges. There Are Some Assumptions Like : Single reaction Plug flow Constant density Controlled environment Main Characteristics : Innovative technique Superior design quality Short residence time Constant distribution We Have Cover Following Markets : USA : Florida, Alaska-Nevada, Texas, Montana, South-Dakota, New-Mexico, New-Jersey,etc. Middle East : Kuwait, Israel, Saudi Egypt, Cyprus, Syria, Jordan, Arabia, Oman, Yemen,etc. Europe : Austria, Poland, Finland, Italy, Andorra, Albania, Sweden, Croatia, Monaco, Malta,etc. Others : Bangladesh, Maldives, Myanmar, Bhutan, China, Pakistan, Nepal,etc. Indian Areas : Assam, Himachal-Pradesh, Punjab, Delhi, Karnataka, West-Bengal, Gujarat, Mumbai, Bihar, Andhra-Pradesh, Orissa, Madhya-Pradesh, Haryana, Rajasthan,etc.

Micro Reactor Systems

Get Price Quote

Micro Reactor Systems They will be a good choice for chemists working with very expensive materials or materials only available in small amounts. They will also appeal to users who wish to minimize the risks associated with hazardous materials or reactions by restricting the reactants or products to a minimum.

SVC REACTORS

Get Price Quote

Usually SVC reactors were imported from Austria for all these years.Now we have manufactured the largest SVC reactor in the country for 60 MVAR SVC system of ABB make.It has been successfully installed and commissioned at a SAIL steel plant since 2 years.

Process Reactor

50,000 Per Units

SVC REACTORS

Get Price Quote

Usually SVC reactors were imported from Austria for all these years. Now we have manufactured the largest SVC reactor in the country for 60 MVAR SVC system of ABB make. It has been successfully installed and commissioned at a SAIL steel plant since 2 years.

Process Reactor

Get Price Quote

Chemical Process Reactor

Get Price Quote

Chemical reactors are vessels designed to deals with multiple aspects of chemical engineering. We are a renowned Chemical Process Reactor Manufacturer, Exporter and Supplier in Maharashtra (India). We are offering a precision based range of Chemical Process Reactors including pressure reactors etc. Our offered Chemical Process Reactors are designed by our professional chemical engineers to maximize the net present value for the given reaction. It requires minimum operating and installation cost. Customers can avail them from us at reasonable prices.Details : It ensures proceeding of the reaction with high efficiency towards the desired output product Normal operating expenses include energy input, energy removal, raw material costs, labor, etc. Energy changes can come in the form of heating or cooling, pumping to increase pressure, frictional pressure loss (such as pressure drop across a 90° elbow or an orifice plate), agitation, etc

process reactors

Get Price Quote

process reactors, GMP Vessel and Receiver, Vertical Vacuum Trap

Chemical Process Reactors

Get Price Quote

Chemical Process Reactors, Heat Exchanger, Adhesive Making Plant