Jindal Roofing Profile Sheets

2,500 Per Square Meter

1000 Square Meter (MOQ)

Profile Sheets

Get Price Quote

1 Container of 20 Feet (MOQ)

Best Deals from Profile Sheets

Double Skin Stainless Steel Roofing Sheet

1,550 Per Square Feet

2000 Square Feet (MOQ)

Composite Floor Decking Profiles

Get Price Quote

20 Ton (MOQ)

Composite floor decking is one of the most effective methods of constructing floors in steel building and very useful in high-rise RCC/Steel buildings. Since they are amalgamated into the floor concrete, they serve the dual purpose of permanent form and positive reinforcement of the floor. Industrial applications. Decking profiles can be effectively used in wide range of infrastructure projects like: Power projects Industrial buildings Multi-storied buildings Supermarkets / Malls Bridges Walkways Platforms etc.

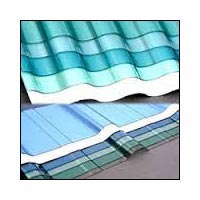

Polycarbonate Embossed Profile Sheets

Get Price Quote

We are in manufacture of all types of polycarboante coorugated shhets, as per the profle match.

Plain Galvanized Roofing Sheet

62 Per Kilogram

500 Kilogram (MOQ)

Galvanized Corrugated Roofing Sheet

50 Per Kilogram

500 Kilogram (MOQ)

Roofing Sheets

Get Price Quote

10 Piece (MOQ)

Galvanized Iron Roofing Sheets

80 - 90 Per Kilogram

1 Ton (MOQ)

Corrugated Sheets

Get Price Quote

500 Piece (MOQ)

Applications: Corrugated sheets use as stable cushion that keeps product safe and sound proof during shipping. Corrugated rolls protects from scratches breaks and dings in all materials, but especially glass, metal and ceramic.

Polycarbonate Roofing Sheets (Multiwall)

36 - 55 Per Square Feet

4ft x 39ft 6.75ft x 39ft

Corrugated Drainage Sheet

Get Price Quote

Multichannel drainage system for efficient drainage during operation. Provided with X-ray opaque line. Extra soft super smooth PVC corrugated sheet for wound drainage. Sterile product for single use.

POLYCARBONATES ROOFING SHEETS

Get Price Quote

This Polycarbonate (PC) are a particular group of thermoplastic polymers having useful features like temperature resistance, impact resistance and optical properties. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications of corrugated profiles, dome lights, flat or curved glazing and sound walls. Polycarbonate Roofing Sheets are highly transparent to visible light, with better light transmission than many kinds of glass. Unlike most thermoplastics, polycarbonate can undergo large plastic deformations without cracking or breaking. Multiwall Polycarbonate Sheets are produced by extrusion process , basically having ribbed section between two layers of polycarbonate sheets. Because of their properties they can be bent and shaped into any profile requiring minimum or no structural fabrication. Available in many thickness and colors they provide excellent UV resistance and light transmissions between 45% to 80 % hence find application in Plant / warehouse Roofing , Pyramids, Domes , Sky lights & Walkways , Interior partition , Roof lights & Swimming Pool Cover & Green house. Fiber-reinforced plastic (FRP) (also fiber-reinforced polymer) is a composite material made of a polymer matrix reinforced with Glass fibers. The original plastic material without fiber reinforcement is known as the matrix. The matrix is a tough but relatively weak plastic that is reinforced by stronger stiffer reinforcing filaments or fibers. Fiber-reinforced plastics are a category of composite plastics that specifically use fiber materials to mechanically enhance the strength and elasticity of plastics. They find typical applications in all components that cannot be produced by conventional die & mold system. FRP have the following properties:• Good strength & Weather durability .• Corrosion resistant. • High impact strength • Fire retardant • Light weight yet strong • Resistant to acid/alkali fumes • Free from problems of cracking, wrapping and buckling. FRP Applications:FRP Panel / Profile, Roof Gutters, Corrugated Sheets, Roofing / Cladding Sheet.

Roofing Sheets

86 Per Kilogram

100 Kilogram (MOQ)

ASA Tile UPVC Roofing Sheets

Get Price Quote

4000 Meter (MOQ)

We wish to take this opportunity to introduce ourselves as manufacturers of sankalp ASA Tile Sheets & uPVC multilayer roofing sheets . We are in a business of suppliers and installation of sankalp upvc multilayer roofing sheets . As per our understanding of your business, sankalp upvc roofing sheets takes care of all your roofing needs . 1. thermal heat insulation 2. sound insulation 3. chemical resistant 4. pressure prevention 5. eco - friendly 6. longevity (last for generations ) 7. hygienic (best for food industry ) 8. corrosion resistance 9. light weight 10. water proof

Aluminium Roofing Sheet Stockists

Get Price Quote

Our organization is positioned at mumbai(india) and has gained immense acknowledgement and a respected place in the market. To provide our buyers with premium products, we make sure only superior grade materials are used for manufacturing them.

PP Roofing Sheets

Get Price Quote

Ours is a quality-driven organization that is engaged in offering only high-quality products. Thus, we use superior grade raw materials for the fabrication of our entire range. We are known for delivering the orders within the specified time frame owing to our modern transit facilities. Features: Excellent physical and mechanical performance High strength and low permeability; high tearing resistance; good deformation adaptability; high puncture resistance; high aging resistance; high UV resistance, anti-acid & alkali Excellent low & high temperature resistance; innocuous, long life span; perfect water proof performance, seepage and humidity resistance Reflective factor, good welding performance and convenient construction Usage: Prevent leakage disposal in waste burying field or waste water or waste dregs disposing field. River bank, lake dam, mine remaining reservoir, tunnel, liquid storage pool(pit, mine). Preventing leakage in subway, basement, tunnel, hole. Anti-salt leakage in roadbed and other groundsill. The plane direction laying of dam, the vertical direction laying for groundsill, used in the construction fence and waste material field.

5 Ply Corrugated Paper Packaging Sheet

450 Per Kilogram

Hi Rib Profile Sheets

415 - 420 Per smt

In order to deliver consistent quality products, we keep our vigil eyes on product development, storage, and final dispatch. We are a reliable name in this arena and thus make sure that the services offered by us for payment are easy to use as well as offer hassle-free and instant transactions. Our Hi Rib Profile Sheets have a sturdy metal body with a smooth and polished surface.

Galvanized Corrugated Sheets

Get Price Quote

We are a reputed firm engaged in exporting and supplying Galvanized Corrugated Sheets. Our Galvanized Corrugated Sheets are precisely engineered by the experts of our reliable manufacturers. They are widely demanded by the customers owing to its supreme quality, excellent finish and high durability. The Galvanized Corrugated Sheets are made available in various sizes, thicknesses and shapes at industry leading prices.