Vessels

Aseptic Design of bottom outlet valve with zero hold up, Customised design incorporated for diverse applications, CIP and SIP style design of vessel, fittings and piping, Injection ports, injection needles available on the top of the lid, Magnetic drive, so no seals, no shaft, thereby eliminating contamination. Mixing head designed for vigorous mixing or low volume blending.

...more

Tray Dryer

We believe that quality keeps us ahead and we are committed to provide highest satisfaction to our customers by providing them quality products at reasonable prices &timely delivery. Our range of products is encompassing of tray dryer, pharmaceutical tray dryer and electric tray dryer. If we talk about its salient features it carries the best features like the fan is dynamically balanced with specially sealed bearing to withstand the high temperature. The try size of tray dryer is 16 x 32 x 1.25 (h) inches and the tray size has a capacity of 6 up to 192 trays. For heating arrangements it has an electrical / steam heating and heaters are accessible and replaceable from outside the dryer. Further the front doors are explosion proof and are locked with the help of spring loaded ball latches with suitable pressure. Lastly we are the chief electric tray dryer manufacturer, exporters from India. Product Code : 08 Features Fan is dynamically balanced with specially sealed bearing to withstand the high temperatureHeating Arrangement - Electrical / Steam heatingDesigned for uniform circulation of hot air in the drying chamberTunnel type dryers wherein trolleys are placed one behind the other and double door loadingElectric heater terminals situated outside the hot zone in case of electrically heated dryers.Heaters are accessible and replaceable from outside the dryerThe front doors are explosion proof and are locked with the help of spring loaded ball latches with suitable pressureTray size is 16 x 32 x 1.25 (h) inchesCapacity : 6 upto 192 trays

...more

Toothpaste Plant

Toothpaste manufacturing plant contains of a key manufacturing vessel also known as Contra Mixer. Contra Mixer works on the principle of Contra rotation of Blades for concurrent beating and scraping operation. The mixer is highly versatile and widely used for manufacturing Tooth Paste, Creams, Cosmetics and other viscous products.

...more

Tablet Coating Pan

Our company manufactures comprehensive array of tablet coating pan used for sugar and film coating of tablets, pellets and granules in pharmaceutical industry. We offer coating pan in different sizes on basis of pan diameter and mixing capacity per batch.Pharma machine are renowned for the supplier of sturdy, easy to uphold, robust and long lasting traditional revolving Coating Pans in national and international market. Coating pans are made from high tensile stainless steel hence it is accessible by separate hot air blower system for film coating of tablet.

...more

Syrup Processing Plant

Sugar and Glucose Transfer System, Sugar Syrup Preparation with efficient bottom entry agitation, Efficient Filtration System for the clear suspension syrups. “CE” marked Equipments are offered with Third Party Inspection & All Electrical Control with ERTL Approval & Test.

...more

syrup making machine

Automatic Oral Syrup Manufacturing Plants are ideal tools for the pharmaceutical industry for the production of Oral Liquids.

...more

Sugar Syrup Making Machine

Syrup Manufacturing Plant involves systems that provide for hygienic manufacturing of liquid syrups in range from 50 Ltrs to 20,000 Ltrs. The plant requires minimum manual handling of liquids that supports maintenance of hygienic processing environment with the use of quality components in the plant. Our Syrup Processing Plant finds application in varied Chemical, Pharmaceutical and food industry. The plant complete with sugar melting vessel, manufacturing vessel, transfer pumps, working platform, inline homogenizer, online sugar syrup pre-filter, storage vessel, piping for complete plant and control panel.

...more

Sterile Processing Plant

We design and manufacture high in tech Sterile Processing Plant with the capacity around 100 liters to 1000 liters. These are well versed with latest technology which makes their operations easier than others. These are also made up of finest quality raw material which enables us in catering excellent quality and error free sterile processing plant. We are nationally and internationally preferable for our most sophisticated range of products. Product Code : 15 Capacity : 100 liters to 1000 liters

...more

Sterile Blending Vessels

APPLICATIONS : Pharmaceuticals Sterile Solutions Vial Ampoules I.V. Fluids Aerosols LVP & SVP Solutions Biopharmaceuticals Vaccines Injectables Human Insulin Serums Plasma Fractions Bacteria and cell cultures LVP UNIQUE FEATURES : Aseptic Design of bottom outlet valve with zero hold up Customised design incorporated for diverse applications Calibrated full view glass for Sterile Mixing Vessel CIP and SIP style design of vessel, fittings and piping Injection ports, injection needles available on the top of the lid Volume monitoring by load cells Process Automation Sterility compliant Magnetic drive, so no seals, no shaft, thereby eliminating contamination Mixing head designed for vigorous mixing or low volume blending

...more

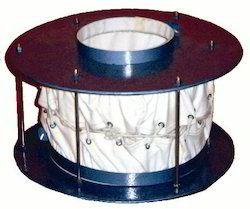

STERILE BLENDING VESSEL

With immense expertise and high industry experience we are one of the prominent and actively engaged in manufacturing, supplying and exporting a Sterile Blending Vessel in Mumbai, Pharma Plant Manufacturer, Maharashtra, India. The offered sterile blending vessel is manufactured by utilizing supreme quality stainless steel materials and latest advanced technology. This Sterile Mixing Vessel is widely used application for pharmaceuticals are Sterile Solutions, Vial, Aerosols, LVP and SVP solution, Syrups etc. Automatic process of Sterile Blending Vessel is design in CIP and SIP system of cleaning. Before dispatching to the clients the Sterile Blending vessel is tested on various parameters to meet International standards. We offer this sterile Blending vessel at cost-effective minimal rates. The Vessel is designed in Cleaned-In-place(CIP) and Sterilized-In-place(SIP) operation Safety Valves and air vent Zero Dead leg Flush bottom outlet values A Load cell for weight measurement Easy to operate Cost effective Magnetically powered drive no seals, no shaft, thereby eliminating the possibility of contamination Pharmaceuticals:- I.V. fluids LVP and SVP solution Sterile Solutions Vial Aerosols Ointments Bio Pharmaceuticals :- Human Insulin Plasma Fractions Bacteria and Cell cultures Serums

...more

Steam Sterilizer

We are a well-known electric Steam Sterilizer exporter from India. The interior doors of our dry steam sterilizers - S.S. 316 chamber with S.S. 304 jacket are well-equipped with special locking and sealing system. For the safety purposes, our dry steam sterilizer is well-endowed with self locking safety. We offer dry steam sterilizer at the most reasonable price. Product Code : 13 Salient Features S.S. 316 chamber with S.S. 304 jacket.Radial or sliding type specially designed doors.Interior doors with special locking and sealing system.Sturdy tubular mounting for the Equipment.S.S. 304 outer cover for insulation.S.S. 304 / S.S. 316 piping with specially designed Tri-clover end connector for the Equipment.Improved temperature uniformity inside the chamber reducing heat losses due to radiation.Prevents simultaneous door opening at a time when process is �ON�.Self locking safety for doors can�t open under pressure. Propack steam sterilizers are designed for best possible adaptation to the customer needs, and the regulations laid down for pharmaceutical products to meet c GMP norms. Propack offers maximum reliability in view of material quality, operations and performance of the equipment. The steam sterilizers can be operated using external steam or with built in steam generators depending upon the availability of the steam. Different cycles can be selected. Depending upon the product to be sterilized.

...more

Soft Gelatin Processing Plant

SALIENT FEATURES : PLC Programmed (optional) for dual speed agitation to reaction mass of Gel Cooker as per defined recipe. Hydraulic Lifting System for top cover of Gelatin Cooker. Medicament Mixing & Homogenizing Vessel. Multi-purpose Mixing & Deaeration Unit with SS Control Panel for carrying out following operation: � Mixing of Medicament � Colour Mixing in Gelatin mass Deaeration of Gel mass. Heat traced transfer pipe line for feeding Gelatin to Encapsulating Machine Vacuum Control System for Deaeration in Gelatin Cooker. Strict compliance to cGMP as per the International Standard norms. SS 316 L contact parts Mirror polished to less than 0.5 Micron RA & SS 304 Non-Contact parts Matt finished. 100% drainable, crevice and dead leg free internal surface. Specially constructed Gelatin Feed Tank with Electronic Heating System.

...more

SIP Modules

Cleaning-In-Place (CIP) and Sterilization-In-Place (SIP) are systems designed for automatic cleaning and disinfecting without major disassembly and assem- bly work. We design, develop, manufacture, supply and install Mobile and Fixed CIP & SIP Units for sanitization and sterilization. The units are custom made, modular, skidded in automated or semi-automated Models as per the required time cycle for cleaning and sterilization as a part of cGMP requirements from portable to large fixed Multi-Tank system.

...more

Shampoo Making Machine

Shampoos are manufactured by simple slow blending in a stirred vessel. Shampoos are cleaning formulations used for a wide range of application, including personal care, pet use, and carpet. Most commonly, shampoos are used for personal care, especially for washing the hair. Consumer product corporations will continue to produce new type of shampoos.

...more

Revolving Coating Pan

Our company manufactures comprehensive array of tablet coating pan used for sugar and film coating of tablets, pellets and granules in pharmaceutical industry. We offer coating pan in different sizes on basis of pan diameter and mixing capacity per batch. Pharma machine are renowned for the supplier of sturdy, easy to uphold, robust and long lasting traditional revolving Coating Pans in national and international market. Coating pans are made from high tensile stainless steel hence it is accessible by separate hot air blower system for film coating of tablet.

...more

Rapid Mixer Granulator

We are the genius Rapid Mixer Granulator machinery suppliers from India engrossed in providing rapid mixer granulator, tableting rapid mixer granulator and rapid mixer granulator machinery at honest prices. As far as its features are concerned rapid mixer granulator have capacity from 10 Liters upto 1200 Liters and the it is covered with basic equipments machine base covered all around by SS flush type panels. Even the frame is provided with a SS staircase & railings. Over the frame there is RMG Bowl with pneumatically open able lid. It is configured with two mixing blades. These mixers are highly efficient, fast, & ensure homogeneous mixing. Lat but not the least we are thankful to our customers who are allowing us to serve them our quality products since long and we are accumulating only positive feedbacks from our clients which prompt us for doing best. Our rapid mixer granulator is available in capacity ranging from 10 Liters to 1200 Liters. These are configured with certain basic equipment and the complete machine base is covered with SS flush type panels. Salient Features The basic equipment consists of powder making machinery base covered all around by SS flush type panels.The machine frame is provided with a sturdy SS staircases & railings.RMG Blow with pneumatically open able lid is provided over the machine structure.Configured with two mixing blades.Material to be mixed are whirled and tumbled close to the bottom of RMG blow with the help of the chopper blades.Lump formation is prevented with the help of chopper tool.These mixers ensure highly efficient, fast & homogeneous mixing.

...more

pure steam generator

Pure Steam Generators exploit a competent evaporation column, thereby giving the highest quality Pure Steam. In addition, when assessment or preservation is required, the components are readily accessible with no need to eradicate or disassemble any of the major components to access the critical areas.Pure steam generator is ideal in sterilization of pipelines, tanks,fermentors etc. It is also suitable for humidification of sterile areas where pure steam is required.

...more

Powder Capsule Multi Mill Plant

Being a pioneer of this industry we offer you a phenomenal range of Powder Capsule Multi Mill Plant and powder capsule processing plant which is the testimony of superior quality. These are widely used in Multi Mill is widely used for wet and dry granulation, pulverisation etc., in Pharmaceuticals, Chemicals, Cosmetics, Ceramics, Colors, Dyestuff, Food products. It is also in demand in various industries like Pesticides, Fertilizers, Spices, Detergents, Insecticides, Plastics, and Resins industries. It is of stainless steel 304 / 316 quality hopper and processing chamber. Subsequently beaters and scrapper blades are made up of stainless steel. In addition to this we are one of the principal capsule multi mill plant manufacturers located in India. Product Code : 11 Salient Features Stainless steel 316 quality hopper and processing chamber.Beaters and scrapper blades made in stainless steel. Can be easily dismantled and cleaned.Cylindrical screen for continuous output.Mill with motor, electrical switchgear along with pillar are mounted on a painted base plate with castors for mobility.Flame - proof electrical motor can be incorporated (optional) designed for continuous operation.Widely used for wet and dry granulation, pulverization, etc.Application : Multi Mill is widely used for wet and dry granulation, pulverization etc., in Pharmaceuticals, Chemicals, Cosmetics, Ceramics, Colours, Dyestuff, Food products etc. It also finds application in Pesticides, Fertilizers, Spices, Detergents, Insecticides, Plastics and Resins industries.

...more

Polishing Pan

Pharma machine are renowned for the supplier of sturdy, easy to uphold, robust and long lasting traditional revolving Coating Pans in national and international market. Coating pans are made from high tensile stainless steel hence it is accessible by separate hot air blower system for film coating of tablet.

...more

pharmaceutical tray dryer

We are one of the best producers and suppliers of Tray Dryer from Mumbai, India. We specially designed this Tray Dryer for drying of granules and food materials in pharmaceutical…

...more

Pharma Processing Plant

Owing to the expertise in the market we are one of the leading manufacturer, exporter and supplier of Cleaning-In-Place (CIP) and Sterilization-In-Place (SIP) module, Pharma Plant India . The offered CIP/SIP Module is designed for the purification and sterilization of pharmaceutical unit, system. The modules are available customized, automated, or semi-automated according to the needs of our valuable customers. In addition to this these products are well tested by our quality control expert to meet International quality standards. CIP/SIP module offers unique features like efficient cleaning, less labor, easy to use, lower cost etc. Unique features :- Sanitary Design to meet all cGMP Criteria Easy to use Safety Less labor Cleaning is faster Orbital tube welding 100% Drianability Long lasting Cost effective Less maintenance required

...more

oral processing plant

The oral processing machines offered by us are high in performance and efficiency and work with precision in their specified application. Our Oral Manufacturing plants are highly automated to ensure fast throughput and minimize the exposure of products during the production process. The plant is customized to suit the variegated demands of the clients in the national and international markets.

...more

Ointment Plant

Ointment Manufacturing Plant

Be first to Rate

Rate ThisOpening Hours