Liquid Transfer Pump Machine

75,000 Per Piece

1 Piece (MOQ)

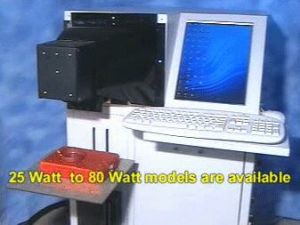

Diode Pump Laser Marking Machine

450,000 Per Piece

1 Piece (MOQ)

Best Deals from Pump Machine

End Pump Laser Machine

Get Price Quote

We are counted as one of the premium manufacturers and exporters of end pump laser machine, based in india. End pump laser machine is available in various specifications to meet different requirements of the clients. These machines serve wide application in electronic parts, plastic key-press, integrate circuit (ic), electrician machine and communication products. Advantages single phase with very low power consumptionworking hrs of diode 100,000 hrssmall in size, occupies very less areasharp beam qualityeasy and stable in operationair-cool machine available with 12 w out put suitable for imagephoto marking metals and plasticsmobile keypad and accessories markingelectronic parts

POP Mixing Machine with Vacuum Pump

Get Price Quote

Single Shot Lubrication Pump Windsor Machine

Get Price Quote

as per the order Piece (MOQ)

Technical Details Mounting Panel installation Connections 1/4” BSP suction port and 1/8” BSP delivery port Weight 1.5 kgs Mounting Position Horizontal or Vertical Operating Fluid Mineral Oils Hydraulic Data Operating Pressure 1500 psi (max) Delivery volume of oil output cc.

Nd-Yag Lamp Pump Laser Marking Machine

Get Price Quote

We are offering nd-yag lamp pump laser marking machine. technical specifications of lw mark g1 type lamp pumped nd-yag cw watts -50w type -lamp - krypton ambient temp. Required 20° ~25°c input voltage -440ac 3ø ac power output -50w loading method -manual lamp change time (statistical av ) 700 hr water required for chiller deionised, 40l repeatability (galvo) ± 3-µ accuracy (galvo) ± 3-µ spot dia at focus of f.l. 160mm 50 µ effective marking area 110×110mm maximum letter height 100mm maximum speed - cycle time typical 0.5sec (8 ~ 10 char, 3mm ht) mode of laser beam q switched cw cooling system direct d.i.water cooling height adjustment when parts are of different heights motorised z axis peak power 100 kw@1khz power consumption max. 7.5 hp ~ 10 hp q switch frequency 0.01 → 50 khz beam roundness excellent weight appx.150 to 300 kg

Inline Gear Pump Filling Machine

Get Price Quote

PLC BASED FILLING SYSTEM. HAVING DIGITAL. THEREFORE QUICK CHANGE OVER FOR DIFFERENT VOLUME. NO JAR NO FILL SYSTEM 2 TO 12 HEAD AVAILABLE. PNEUMATICALLY OPERATED. CONTACT PARTS IN STAINLESS STEEL 304/316 QUALITY. WITH S.S SLATE CONVEYOR. FLAME PROOF MODEL AVAILABLE. POWER 230 VOLTS, 50 Hz. USED FOR HIGH VISCOSITY MATERIAL LINK GREASES, ADHESIVE ETC. VACCUMETRIC FILLING ALSO AVAILABLE.

Dual Pump Dyeing Machine

Get Price Quote

Our well-structured warehouse is properly maintained and installed with diverse amenities required for the safe storage of the products. Moreover, we keep on updating the unit for enhanced safety. We are supported by a reliable team of packaging experts who have immense experience in this domain and capable of catering to the standards and customized packaging requirements.

Gear Pump Filling Machine

Get Price Quote

Apart from the range of volumetric and vacuumetric filling machine Liquipack now introduces FLOWMETRIC FILLING MACHINE for various types of liquids. This machine works on the principle of metering the flow of liquid through digital control. The liquid to be filled flows from reservoir tank to the container through Gear pump, controlled by PLC. Convenience of digital volume settings through PLC makes the machine user friendly.

Perfume Spray Pump Crimping Machine

Get Price Quote

100% pneumatically operated machine. (completely flameproof) Special design, heavy duty pneumatic cylinder. Very easy operation. Automatic pressure adjust of pneumatic operation as per require. Replacing crimping collet is a very easy job. Height adjustable by hand wheel. S.S. covering of main machine body. FRL provided with the machine. Machine can be mounted on top of conveyor by S.S. platform or with the powder coated stand. Two modes available: a) Foot operating. b) 'Continue' Operating.

Peristaltic Pump Filling Machine

Get Price Quote

Peristaltic Pump timer based liquid filling machine. We have single head followed by two head and four head models where only one operator will be occupied for two head model and two operators will be occupied for four head model. In the Semi-automatic machine, the filling process is operated on foot switch so the machine starts filling once the foot switch is pressed. The operator needs to place the empty bottlesjarsdrums and remove the filled bottlesjarsdrums manually after filling is done. In this model, the filling is done based on the number of rotation fed as input in the pump. These machines are very much suitable for the multiple products to be done where contamination between the liquids are not allowed. We change the contact part silicon tube and we can do multiple products without any hassle. We can offer any customization in the machine as per the requirement of the customers.

Portable Pump Dip Tube Cutting Machine

Get Price Quote

Machine Applications Perfume Pump Dip Tube Cutting Aerosol Pump Dip Tube Cutting Dip Tube Cutting Plastic Tube Cutting

Gear Pump Filling Machine

Get Price Quote

We are the preeminent manufacturer and exporter of gear pump filling machines, which are diligently designed by the skilled engineers. They have incorporated various efficiency-increasing features in our gear pump filling machines, which have assured the clients in regard of their ability to perform in the hardcore industrial applications. Advantages simple in designeasy operationhighly accuratelonger lifehigh efficiency specifications drip free nozzle with filling range of 100ml to 500mlavailable from 4 head to 12 headmitsubishi make plc system with t" touch screen and vfd control for conveyor speed controlcontact parts in stainless steel 304 qualitybody frame made up of stain lees steelpneumatically operated stopper gates for bottle entry and exitin built memory to store 25 filling setting datefilling accuracy of -/+ 0.15%setting of volume, speed of filling through plc

Automatic Gear Pump Based Filling Machine

Get Price Quote

Description / Specification of Automatic Servo Piston Filling Machine Drip free nozzles with filling range of 100ml to 1000ml, with drip tray for accidental drip. Mitsubishi make PLC system with 7" Touch Screen and VFD control for conveyor speed control. Contact parts in Stainless steel 304 quality. Body frame made up of M.S. with Powder coating or stainless steel. Capable of automatic intake of empty bottles / container on to the filling station and discharge after filling bottles with the help of stop and release lever pneumatically operated. Neck entry Nozzle system so that the nozzle enter inside the container before filling to avoid spillage. Enclosed body with transparent Acrylic doors in front and back. Pneumatically operated stopper Gates for bottle entry and exit. Having Tank of 200 Ltrs of Stainless steel with float valve for level controlling. In built memory to store 25 filling setting data. Setting of Volume by PLC

Discharge Dampeners for reciprocating pump

Get Price Quote

API674 pump discharge pulsation dampeners are often a necessary accessory for multi-plunger high pressure reciprocating pumps, as such pumps can produce damaging levels of pulsation and vibration as each slug of liquid is discharged from the cylinder out through the discharge valve and into the pipework. As the slug of liquid exits the pump cylinder it is will be pushed into a pipeline that is already full of liquid. If the liquid volume in the pipe cannot be fully compressed to make space for this new slug of liquid, or if the pipe containing the liquid will not stretch to give some additional volume, then the pressure in the liquid will rise and a pressure pulse will occur. How high this pressure pulse goes will depend on how fast the slug of liquid is pushed out it into the pipeline, the compressibility of the liquid already in the pipeline and the stiffness of the pipe material. The magnitude of the pressure pulses that are generated at the pump, and the forces that they impose on the piping system can be assessed using the guidance given in API674. This specification, produced by the American Petroleum Institute provides conservative guidance that enables the use of simulation analysis to design out these pulsation forces either through modification of the piping system, or by the installation of a pulsation dampener in the discharge pipework, usually positioned immediately downstream of the pump. This discharge dampener may take one of several forms, however, whichever form is fitted they all have the same thing in common in that they introduce a calculated amount of elasticity into the piping system that will expand and/or contract as each new slug of liquid leaves the pump and enters the piping system, thereby allowing the system to accept each new slug of liquid with minimal pressure rise. Our liquid filled discharge dampeners offer full compliance with API674 by utilising the compressibility of the liquid volume, and the pressure drop across the equipment. We can demonstrate compliance with API674 through our full API674 analysis service that simulates the sizing and effectiveness of the solution according to the most rigorous design approach. Design and manufacture of the equipment will be fully in accordance with your specifications, such that the dampeners become part of the pipeline, and are simply forgotten. They are a true fit and forget item. With hundreds of units supplied, and over 30 years of experience in supply, our equipment has a proven track record of reliability and performance. Carbon steel construction is standard, but other materials such as 304/316 stainless steel, duplex or super duplex steels are available for pressures ranging from as little as 50 BarG and upwards to match the rating of your piping. If you can design the piping can take the pressure, then we can build a dampener that will fit right in. Whether this just requires some straight forward pressure vessel calculations, or fully detailed Finite Element Analysis (FEA), to prove the design, our in-house engineers have the tools needed to prove the design. Units can be built to all British, European, American and Indian pressure vessel codes, with CE marking will be applied to equipment that is destined for the European Union. A few of the fluids that we have built equipment to handle are; Water, Ammonia, Carbamate, Hot oils, Bitumens, CO2, MEG, TEG, plus various hydrocarbons

Gear Pump Filling Machine

Get Price Quote

we are the preeminent manufacturer and exporter of gear pump filling machines, which are diligently designed by the skilled engineers. they have incorporated various efficiency-increasing features in our gear pump filling machines, which have assured the clients in regard of their ability to perform in the hardcore industrial applications.

Manual Perfume Pump Crimping Machine

16,500 Per Piece

vacuum pump milking machine

Get Price Quote

vacuum pump milking machine, Vacuum Pump, Bottle Filling Machine

syringe pump machine

Get Price Quote

syringe pump machine, airocide air purifier machine, Bipap Machine

pump machine

Get Price Quote

pump machine