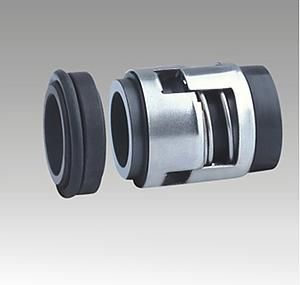

Centrifugal Pump Conical Spring Seal

1,000 - 2,000 Per

1 Set (MOQ)

Alfa Type Seals

1,600 - 3,800 Per piece

5 Piece (MOQ)

WAVE SPRING SEALS Wave Spring Seals are designed for bi-directional use and work with highly viscous, abrasive media, water, oils, fuels, light aggressive chemical substances and liquids containing solid particles. Most of the components are interchangeable, hence it proves economical and easy to maintain. All components are held together by snap ring which helps in easier installation and removal. Industrial Application: Sugar, Waste Water, Oil Refinery, Paper & Pulp Industries etc. Face Materials: Tungsten Carbide, Carbon, Silicon Carbide, Ceramic, Special Cast. Metal Component: S.S 304, S.S 316. Secondary Seal: Viton, PTFE, EPDM, NBR, FKM. Operating Limits:Alfa Type Seal Lineproof Engineering is instrumental in offering superior quality Alpha Type Mechanical Seals. These Alpha Type Mechanical Seals have sophisticated design which can be used in high slurries application. Industrial Application: Hygienic Dairy, Pharmaceutical & Food Beverages. Face Materials: Tungsten Carbide, Carbon, Silicon Carbide, CFT. Metal Component: S.S 304, S.S 316. Secondary Seal: Viton, PTFE.

Best Deals from Pump Seals

Pump Seals

800 Per Bag

1 Piece (MOQ)

Grundfos Pump Bellow Seal

Get Price Quote

Raw material that we source is unprocessed and of excellent quality as we procure it from the trusted sources of the market. Before obtaining it, our experts check it thoroughly. We allow our patrons to make payment through a variety of methods. We are comfortable with patrons making payment through online or offline mediums that are legal and trusted. Features : Sturdy material Precision made Industrial application

Seals For O.E.M PUMPS

Get Price Quote

Available Range: Multi-spring double seal for ITT Flygt® pumps Wave-spring,balanced seal for Alfa Laval® SR and LKPL pump Elastomer bellows seals for KSB Pump Elastomer bellows seals for Grandfos Pump Rubber bellows seals for Grundfos ®® cp-series pumps. Conical spring 'O'-Ring mounted balanced seal for K.S.B ® movi series pumps. O'-Ring mounted seals for Alfa Laval® lkh series pumps flowserve® hydrotitan series pump seal flowserve® primotitan series pump seal flowserve® supertitan series pump seal Agitator Mixer seal for Alfa Laval® pumps single unbalanced seal for Alfa Laval® (SR serie,LKPL serie)pumps

Cryostar Pump Seal

1,500 Per Piece

1 Piece (MOQ)

Alfa Laval Pump Seals

Get Price Quote

K.S.B. Pump Seals

Get Price Quote

1 Container (MOQ)

MAK-TECH SEALS offer a wide range of seals from stock and to special order, to suit K.S.B.® equipment, especially centrifugal and waste-water pumps.MTS 127B to suit eta- and sy- series pumpsMAK-TECH SEALS manufacture and stock ‘O’-Ring mounted conical spring rotaries with MTS EBG1 boot mounted stationaries, to give operating dimensions to DIN L1N, for “ETA-” series pumps with “SY-, SYA-, SYN-, or SYT-” designations. These seals are available from stock in materials especially suitable for hot water duties.

Water Pump Mechanical Seal

1,200 Per Piece

Pump Mechanical Seals

Get Price Quote

Applications specially design for mechanical seal component lapping like : silicon carbide, tungsten carbide, ceramic, carbon. Chrome cast etc. Specifications lapping plate outside diameter : 24" (609mm)lapping plate speed : 60 rpmno. Of conditioning rings : 3no. Of lapping plate : 2conditioning ring inside diameter : 9.75" (248mm)height of working face : 35"(889mm)

mechanical pump seals

Get Price Quote

10 Piece (MOQ)

Water Pump Seals

Get Price Quote

Flygt Pump Seal

Get Price Quote

Suitable for pastes, slurries and other applications in submersible pumps.

Water Pump Seal

Get Price Quote

We are the trusted global manufacturers and exporters of high quality Water Pump Seals that are the primary part of the cooling system. Our belief in engineering best quality products, we make sure that the quality of our Water Pump Seals is simply indisputable. Besides, our Water Pump Seals are easily available on leading market prices. Features Rugged constructionMade from high quality raw materialsEasy to installHighly durable Applications Water pumpsSewage pumpSubmerged pumpsChemical pumps

Grundfos Pump Seals

Get Price Quote

Series AES-016 Grundfos pumps seals are very easy to replace and gives maximum reliability. It is durable and made from hardwearing material which prevent he downtime and prolong the lifetime of the seal. All axial movement has been eliminated, preventing wear of the shaft and the rubber parts. There is o special tool required to replace the seal or dismantling the pump. FEATURES It gives long and reliable seal life. Easy to install without any tool

mechanical pump seal

Get Price Quote

We are dealers for Mechanical Seal Coupling used in CRI make High Pressure Pumps. Size of the seals 12mm & 16mm available used for CRI High pressure pumps for 2 series and 4 series.

Cartridge Mechanical Pump Seal

Get Price Quote

Cartridge Mechanical Pump Seal, TBM 510 Teflon Bellow Seal

Grundfos Seals

Get Price Quote

Grundfos Seals, Silicon Carbide Rings, Tungstun Carbide Rings, carbon tubes

mechanical pump seal

Get Price Quote

mechanical pump seal, Mechanical Seal, Mechanical Shaft Seal

water pumps seal

Get Price Quote

water pumps seal, mechanical seal rotary joint, pumps grafoil product

mechanical pump seal

Get Price Quote

mechanical pump seal, V Rings, Heavy Duty Seals, Stuffing Box

Water Pump Mechanical Seals

Get Price Quote

Water Pump Mechanical Seals

Concrete Volute Pump Seal

Get Price Quote

Concrete Volute Pump Seal, bearing isolators

Water Pump Seal

Get Price Quote

Water Pump Seal, Mechanical Seal, Hydraulic Seal, Pump Seal