Slurry Non Metallic Pump Seal

Designed to handle abrasive particles up to 30% by weight. Specially designed Back plate of pump and Impeller in this particular seal type ZR32D which gives better seal life and performance. Hydraulically balanced faces for excellent seal reliability. Specially coated spring is located outside the process. Flushing helps to lubricate the seal faces from atmospheric side of mechanical seal. Features Slurry seal. Double seal for Non metallic pump. Standardized modular design. Inside Mounted. Materials Seal Ring Faces : SiC and Carbon Seat Faces :SiC and Ceramic Elastomer : Viton, TTV, FEP and FFKM MOC : SS 316, PVDF – CHANGE OF MOC ON REQUEST Operating Capabilities Shaft Dia. :20mm to 80mm Pressure : Full Vacuum to 8 bar Temperature : up to 180°C Speed: 3000 r.p.m. Applications Specially developed for steel plants on CRM (Cold Rolling Mill) in acid circulation pumps for PP, PVDF & PFA Lining Pump. What is Slurry Seal ? Slurry Seal For Non-Metallic Pump Seal Type ZR32/D IMS have been carefully designed and manufactured with great precision and care. Please Visit us to see our full range of Slurry Seal For Non-Metallic Pump Seal Type ZR32/D IMS to meet all your requirements. We are the manufacturer of Slurry Seal For Non-Metallic Pump Seal Type ZR32/D IMS in Mumbai INDIA.

...more

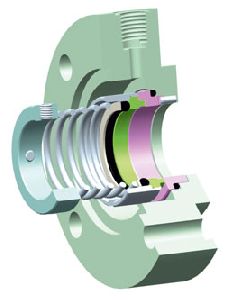

Single Cartridge Seal

The Universal Cartridge ZR29/S Series is a modular cartridge seal family that includes elastomer o-ring pusher seal designs. Type ZR29/S single seal arrangements incorporate an elastomer o-ring as the secondary sealing member. A common seal head/mating ring set, utilized throughout all versions, is reversible to allow rotating. Seat/mating ring or rotating seal head operation, and is interchangeable with metal bellows seal heads. Seal has an optional quench gland with carbon ring throttle bushing. Features Balance Pusher Seals available in Single and Dual Configuration used for Sealing Environmentally. Dual Directional. Stationary spring design. Reversible Seal Head. No clogging Wave Spring outside the Product. Components in Cartridge Design are Builds for the Highest Reliability and Simple Installation. Hydraulic Balance Seal Permits using high Pressure as well as it Create Low Heat Generated on Faces and provides long Life. Unitized, Easy-to-Fit Design. Materials Seal Ring Faces :TC and SiC Seat Faces : SiC and TC Elastomer : Viton, PTFE, FEP and FFKM End fitting MOC : SS 316,HAST-C and Carpenter 42 MOC : SS 316 – CHANGE OF MOC ON REQUEST Operating Capabilities Shaft Dia. : 25mm to 100mm Pressure : Up to 18 bar Temperature : -30°C to 260°C Speed: 3000 r.p.m.

...more

Rubber Bellow Mechanical Seal

The Seal Type 21 is a Compact Single Spring Rubber Bellow Mechanical Seals for universal general purpose for Water / Water Based Solution like Oils, Fuels and Other Fluids and even with some Content with Abrasive and for a very wide operating condition designed for Centrifugal Pump. Rotary Equipment and Industrial applications (Food Processing, Water System, Waste Water Treatment for Petrochemical Processing, Pulp and Paper) Features Single, low cost and mass produced Mechanical Seal with Rubber Bellow. Central Point Non-Clogging Coil Spring Seal. Spring Design Seal is suitable for duel-direction of Shaft Rotation. Bellow Design Seals for Pressure supported and eliminates folds. Bellow Seals Protecting against Twisting. Unitize, easy-to-fit design seals Materials Seal Ring Faces : Cabon, SiC and TC Seat Faces : NiR, Ceramic, SiC and TC Elastomer : Viton, Neoprene, EPDM, NBR and Buna-N MOC : SS 304 / SS 316 Operating Capabilities Shaft Dia. : 10mm to 100 mm Pressure : Up to 8 bar Temperature : -20oC to 180oC Speed: 3000 r.p.m. Rubber Bellow Seals have been carefully designed and manufactured with great precision and care. Please Visit us to see our full range of Rubber Bellowl Seals to meet all your requirements. We are the manufacturer of Rubber Bellow Mechanical Seal in Mumbai INDIA.

...more

Reverse Balance Multi Spring Seal

Seal Type 17 Mechanical Seals are Externally Mounted Reverse Balance design Seal which having ‘O’ Ring as a Secondary Sealing member. Secondary Sealing member can be changed as per Chemical Compatibility. All Metal Components including spring are Isolated from Aggressive media Sealing. Simplicity in Checkout Function and Cleaning Possibility as this Mechanical Seal located easily access outside the pump. The Single Design Seal can be installing as Dual Back to Back Arrangement and can operate on Low Barrier Fluid Pressure due to its Reverse Balance Design feature. We are the top manufacturer of Reverse Balance Multi Spring Seal. Features Single Acting Mechanical Seal. Dual Directional Mechanical Seal. Outside Mounted Mechanical Seal. Reverse Balanced Design. Multi Spring design Mechanical Seal . Materials Seal Ring Faces : Carbon and SiC Seat Faces : Ceramic and SiC Elastomer : Viton, EPDM, TTV, FEP and FFKM MOC : SS 316, Hast -C and Alloy – 20 Operating Capabilities Shaft Dia. : 16mm to 70mm Pressure : Up to 8 bar Temperature : Up to 120oC Speed: 3000 r.p.m.

...more

ptfe bellow seal

Seal Type 23 Mechanical Seals are Specially Designed for using Extremely Corrosive Duties. All Metal Components are including springs are Isolated from the Sealed, Aggressive Medium. These Seal Design Faces are molded with Glass Filled PTFE with Highly Flexible PTFE Bellow. Simple checkout method function and cleaning possibility as this Mechanical Seal located easily accessible outside the pump. Features PTFE Bellow Mechanical Seal. Dual Directional Seal. Outside Mounted Seal. Hydraulically Balanced PTFE Bellow Mechanical Seal. Multi-Spring Design Seal. Materials Seal Ring Faces : Cabon, SiC and TC Seat Faces : Ceramic and SiC Elastomer : PTFE and GFT MOC : SS 316, Hast -C and Alloy 20 Bellow MOC : PTFE + GFT Composite Operating Capabilities Shaft Dia. : 16mm to 80 mm Pressure : Up to 5 bar Temperature : -30oC to 180oC Speed: 3000 r.p.m. PTFE Bellow Seals have been carefully designed and manufactured with great precision and care. Please Visit us to see our full range of PTFE Bellow Seals to meet all your requirements. Superproof Seals Engineering are the manufacturer of PTFE Bellow Seals in Mumbai INDIA.

...more

Metal Bellow Cartridge Seal

Type 27/C – Grafoil Packing Cartridge mechanical seals are destined for petrochemical, chemical, pharmaceutical and food processing industry, for process pumps and other equipment with rotating shaft. Rotating bellows design acts to clear convolutions and prevent accumulation of debris. These bellow seals are constructed by welding a series of diaphragms together at the edges to form a bellows unit. Recommended for high temperature mediums e.g. hot oils, pitch, tar and other hydrocarbons, fuels, liquid gases and other mediums with low content of abrasives. Features Single Acting. Dual directional. Inside mounted. Inherently Balanced Mechanical Seals. Independent of direction of rotation. Unitized, Easy-to-Fit Design. Materials Seal Ring Faces : Carbon, SiC and TC Seat Faces : TC and SiC Elastomer : Flexible Graphite End fitting MOC : SS 316,HAST-C and Carpenter 42 Bellow MOC : HAST -C, AM350 and Inconel Operating Capabilities Shaft Dia. : 25mm to 100mm Pressure : Up to 25 bar Temperature : -70°C to 350°C Speed: 3000 r.p.m. Balance Cartridge Mechanical Seals are carefully designed and manufactured with great precision and care. Please Visit us to see our full range of Balance Cartridge Mechanical Seals to meet all your industrial requirements. We are leading manufacturer of Balance Cartridge Mechanical Seals in Mumbai INDIA.

...more

Dry Running Seals

Seal Type SPD34 and SPD34/B Mechanical Seals are designed for Top, Bottom and Side Entry Drives in Agitators, Mixers OR Blenders and where Non-Aggressive and Non-Hazardous Media are Sealed with the use of Cooling Liquid preventing against Dry Running. Construction of MOC designed of these Seals purpose of holding whole Rotary Parts together with the help of Snap Rings which eases while Installation and Removal of Seals.

Material : Metal

Shape : Round

Pressure : ull Vacuum to 8 bar

Temperature : Upto -30°Cto150°C

Speed : 300 RPM

...more

Double Semi Cartridge Seal

Designed to handle solids up to 20% by weight. Hydraulically balanced faces for excellent seal reliability. Springs are located outside the process. Flushing helps to lubricate or cool the seal faces from atmospheric side of mechanical seal. They are cost effective for basic application such as Centrifugal Pumps and other Equipment with Rotating Shaft, Handling Crystallizing Slurry, Suspended Solid Slurry, Saturated Chemical Slurry, General Chemical Slurry. Features Slurry seal. Standardized modular design. Single Acting. Mechanical Seals. Inside Mounted Materials Seal Ring Faces : TC and SiC Seat Faces : SiC and TCs Elastomer : Viton, TTV, FEP and FFKM End fitting MOC : SS 316,HAST-C and Carpenter 42 MOC : SS 316 – CHANGE OF MOC ON REQUEST Operating Capabilities Shaft Dia. :20mm to 80mm Pressure : Full Vacuum to 8 bar Temperature : -30°C to 260°C(Depending upon Elastomer) Speed: 3000 r.p.m. Double Semi Cartridge Seal are carefully designed and manufactured with great precision and care. Please Visit us to see our full range of Double Semi Cartridge Seal to meet all your industrial requirements. We are leading manufacturer of Double Semi Cartridge Seal in Mumbai INDIA. Search Product Search for: Quick Contact Form Your Name (required) Your Phone (required) Your Email (required) Your Message

...more

Double Cartridge Seal

Double Cartridge Seal Type ZR28/D are Recommended for Clean and dirty media application . Seal can tolerate reversal pressure. Double Cartridge Seal Type ZR28/D is Standard for using where Corrosive Liquid are being Processed. We are the top manufacturer of Double Cartridge Seal Type ZR28/D in mumbai, INDIA This Type of Seals is designed for using for Petroleum Products, Low Aggressive Chemicals and Refrigerants in Centrifugal pumps and other Equipment with Rotating Shafts. Features Balance Pusher Seals available in Single and Dual Configuration used for Sealing Environmentally. Dual Directional. Stationary spring design. Heavy Duty Seal Faces remain flat during Operation to minimize Leakage. Components in Cartridge Design are Builds for the Highest Reliability and Simple Installation. Hydraulic Balance Seal Permits using high Pressure as well as it Create Low Heat Generated on Faces and provides long Life. Unitized, Easy-to-Fit Design. Materials Seal Ring Faces : Cabon, TC and SiC Seat Faces : SiC and TC Elastomer : Viton, PTFE, and FFKM End fitting MOC : SS 316,HAST-C and Carpenter 42 MOC : SS 316 – CHANGE OF MOC ON REQUEST Operating Capabilities Shaft Dia. : 20mm to 100mm Pressure : Up to 15 bar Temperature : -30°C to 260°C Speed: 3000 r.p.m.

...more

Conical Coil Spring Seal

Seal Type RE-06 Conical Coil Spring Mechanical Seal Seal Type RE-06 seal looking from Sliding Face of the Rotating Seal Ring is designed as Right Hand Shaft Rotation which needs Right Hand Spring and Vice Versa. These Seals are Cost Effective Seals for Basic Application Equipment such as Centrifugal Pump and other Equipment with Rotating Shaft, Handling Water, Oils, Fuels, Mild Chemicals and Liquids Containing of Low Quantity of Abrasive. We are the manufacturer of Conical Coil Spring Mechanical Seal, Pusher Mechanical Seals in Mumbai INDIA. Features Conical Single Coil Spring Mechanical Seal. Inside mounted. Unbalanced Pusher Mechanical Seals. Spring design depended on Shaft Rotation with Central Tapered Spring. Materials Seal Ring Faces : Cabon, SiC and TC Seat Faces : NiR, Ceramic, SiC and TC Elastomer : Viton, Neoprene, EPDM, NBR and Buna-N MOC : SS 316 Operating Capabilities Shaft Dia. : 10mm to 100mm Pressure : Up to 7 bar Temperature : -20oC to 140oC Speed:3000 r.p.m.

...more

Balance Cartridge Seal

Seal Type 26B/C are Recommended for Clean media application. Seal Type 26B/C is Standard for using where Corrosive Liquid are being Processed. Construction of these Seal designs holds whole Rotary Parts together with the help of Snap Rings which is make easiest for Installation and Removal. This Type of Seals is designed for using for Petroleum Products, Low Aggressive Chemicals and Refrigerants in Centrifugal pumps and other Equipment with Rotating Shafts. Features Balance Pusher Seals available in Single and Dual Configuration used for Sealing Environmentally. Dual Directional. Mechanical Seal Drive – Reduces Slippage on Shaft or Sleeve to Eliminate Galling and Premature Wear. Heavy Duty Seal Faces remain flat during Operation to minimize Leakage. Components in Cartridge Design are Builds for the Highest Reliability and Simple Installation. Hydraulic Balance Seal Permits using Higher Pressure as well as it Create Low Heat Generated on Faces and provides long Life. Flushing Ports helps to reduces the Heat for Uniform Face Cooling. Advance designed Spring Holder Pimping Ring of Flushing Spring area. Unitized, Easy-to-Fit Design. Materials Seal Ring Faces : Cabon, TC and SiC Seat Faces : SiC and TC Elastomer : Viton, PTFE, and FFKM MOC :SS 316, HAST-C Alloy – 20 Operating Capabilities Shaft Dia. : 10mm to 100mm Pressure : Up to 35 bar Temperature : -30°C to 260°C Speed: 3000 r.p.m. Balance Cartridge Seal are carefully designed and manufactured with great precision and care. Please Visit us to see our full range of Balance Cartridge Seal to meet all your industrial requirements. We are leading manufacturer of Metal Bellow Seal in Mumbai INDIA.

...more

Single Coil Spring Seal

The Seal Type RE-07 with Single Spring design and is depended on the Shaft Rotation. Looking from Sliding Face of the Rotating Seal Ring is designed as right hand Spring for Shaft Rotation and vice-versa. In Seal Type RE07 (‘O’ Ring Type) is designed as Torque Transmission from Drive Collar to Spring and Seal Ring. In Seal Type RE08 (‘V’ Packing Type) is designed as Torque Transmission from Drive Collar to Spring and Seal Ring to be done through Sturdy Drive Lugs. These Seals is cost effective for Basic Application Equipment such as Centrifugal Pump and other Equipment with Rotating Shaft, Handling Crystallizing Slurry, Suspended Solid Slurry, Saturated Chemical Slurry and General Chemical Slurry. Features Single Acting Unbalance Pusher type Mechanical Seal. Inside Mounted Mechanical Seal. Spring Design depended on shaft rotation. Type RE-07 seal having Universal Chemical Compatibility due to design of PTFE Elastomer Materials Seal Ring Faces : Cabon, SiC and TC Seat Faces : Ceramic, SiC and TC Elastomer : Viton, PTFE, GFT, TTV, EPDM, NBR, Buna-N MOC : SS 316 Operating Capabilities Shaft Dia. : 10mm to 100mm Pressure : Up to 10 bar Temperature : -20oC to 150oC Speed:3000 r.p.m.

...more

Multi Spring Mechanical Seal

Seal Type 12&13U Seal Type 12U is recommended for clean media application. Seal Type 12U is Standard for using where Corrosive Liquid are being Processed. PTFE Wedge Construction of the Secondary Sealing Member provides Universal service application. Construction of these Seal designs holds whole Rotary Parts together with the help of Snap Rings which is make easiest of Installation and Removal. These Type of Seal designed and used for Petroleum Products, Low Aggressive Chemicals and Refrigerants in Centrifugal pumps and other Equipment with Rotating Shafts. Features Unbalance Pusher Seals available in Single and Dual. Configuration used for Sealing Environmentally. Dual Directional. Mechanical Seal Drive – Reduces Slippage on Shaft or Sleeve to Eliminate Galling and Premature Wear . Components in Cartridge design are builds for the Highest Reliability and simple Installation. Flushing Ports helps to reduces the Heat for Uniform Face Cooling. Seal Type 12U is ‘O’ Ring Seal design which helps to Eliminate Scoring on Shaft and Sleeve area. Use of ‘O’ Ring Design is depends on suitable applications. Seal Type 13U is Wedge design which helps to Creates Positive Seal use in Extreme Temperature, Chemical application. Using of suitable Coating on sealing area to Eliminate Scoring on Shaft and Sleeve Materials Seal Ring Faces : Cabon, SiC and TC Seat Faces : Ceramic, SiC and TC Elastomer : Viton, PTFE, GFT, TTV, EPDM, NBR, Buna-N MOC : SS 316, Hast -C and Alloy – 20 Operating Capabilities Shaft Dia. : 10mm to 100mm Pressure : Up to 10 bar Temperature : -20oC to 260oC (Depending upon Elastomer) Speed: 3000 r.p.m.

...more

Single Spring Mechanical Seal

Seal Type 15U& 16U Seal Type 15U Single Spring Mechanical Seal are are designed and manufactured to meet all the requirements and most suitable for this applications. These seal are Internally Mounted Unbalanced design which Seal having ‘O’ Ring as a Secondary Sealing member. Seal Type 16U Mechanical Seal are Internally Mounted Unbalanced design which Seal having PTFE Wedge as a Secondary Sealing member. Secondary Sealing member can be changed as per Chemical Compatibility. The Helical Coil Spring designed Seal help to Seal the Dirty and Clogging type of application. Construction of these Seals designs hold whole Rotary Parts together with the help of Snap Rings which is make easiest for Installation and Removal. Features Single Acting Unbalance Pusher type Mechanical Seal. Dual Directional Mechanical Seal. Inside Mounted Mechanical Seal. Independent Direction of Rotation. Type 62 seal having Universal Chemical Compatibility due to design of PTFE Elastomer Materials Seal Ring Faces : Cabon, GFT, SiC and TC Seat Faces : Ceramic, SiC and TC Elastomer : Viton, PTFE, EPDM, NBR, Buna-N MOC : SS 316 Operating Capabilities Shaft Dia. : 10mm to 100mm Pressure : Up to 8 bar Temperature : -20oC to 200oC (Depending upon Elastomer) Speed: 3000 r.p

...more

Metal Bellow Seal

Type 24 -O’ ring type mechanical seals are destined for petrochemical, chemical, pharmaceutical and food processing industry, for process pumps and other equipment with rotating shaft. Rotating bellows design acts to clear convolutions and prevent accumulation of debris. These bellow seals are constructed by welding a series of diaphragms together at the edges to form a bellows unit. Recommended for high temperature mediums e.g. hot oils, pitch, tar and other hydrocarbons, fuels, liquid gases and other mediums with low content of abrasives. Features Single Acting. Dual directional. Inside mounted. Inherently Balanced Mechanical Seal. Independent of direction of rotation. Materials Seal Ring Faces : Carbon, SiC and TCc Seat Faces : TC and SiC Elastomer : Viton, PTFE, FEP, EPDM and FFKM End fitting MOC : SS 316, Hast- C and Carpenter 42 Bellow MOC : HAST – C, AM350 and Inconel Operating Capabilities Shaft Dia. : 25mm to 100mm Pressure : Up to 25 bar Temperature : -30°C to 260°C Speed: 3000 r.p.m. Metal Bellow Seal (O-Ring Type) are been carefully designed and manufactured with great precision and care. Please Visit us to see our full range of Metal Bellow Seal (O-Ring Type) to meet all your requirements. Superproof Seals Engineering are the manufacturer of Metal Bellow Seal (O-Ring Type) in Mumbai INDIA.

...more

Cyclone Separator

Cyclon Separator Series – CS 100 Performance Limits Maximum solid contents ………………… 15 % by weight Max. viscosity of Liquid……………………. 20 centistokes Pressure differential desired …………… 2 to 8.5 Kg Metal Parts Cyclon Separator Shell : Carbon Steel / SS 316/SS304 Secondary Seal : PTFE Specifications Size …….………………………. ½” NPT Design Pressure…….…… 180 Kg Working Pressure …….…160 Kg Max. Temperature …….. 200°C Cyclon Separator CS 100 improves mechanical seal life by cleaning the stream of process fluid to flush the mechanical seal. This is fitted in between pump discharge and seal flush port line, to remove abrasive particles which can cause damage the mechanical seal and reduce its recommended operational life.

...more

Thermosyphon Vessels

Thermosyphon Systems – Series STV – 100 Performance Limits Capacity : 7.5 Liter Hyd. Test Pressure : 30 Kg Working Pressure : 20 Kg Max. working temp.: 180°C Heat Transfer area of cooling coil : 0.3m² Cooling water flow rate Recommended: 12 Ltrs /min Max. Level Value : 5.5 Ltrs Min. Level Value : 3.5 Ltrs Metal Parts Thermosyphon Shell : Carbon Steel / SS 316/SS304 Cooling Coil: SS 304 / SS 316 Accessories Pressure Gauge (0- 40 kg/c m²) For Pressure Measuring of the vessel Level Gauge For Liquid Level Indicate of the vessel Hand Pump For recharge of the vessel With additional quantity of barrier fluid when Thermosyphon is under pressure and Liquid level is low. Connection Size: Buffer fluid Inlet – A ½” NPT Buffer fluid Outlet – B ½ NPT Cooling water Inlet – C ½” NPT Cooling water Outlet – D ½” NPT Hand Pump Connection – E – ¼: NPT (Refilling Connection) Filling Connection – F –1 ¼” NPT Pressure Gas Connection – G ½” NPT Pressure Gauge Connection – H 3/8” NPT Drain – I ½” NPT Safety Valve Connection – J ½” NPT Thermosyphon vessels can be used to provide a source of clean, Pressurized barrier fluid to Double mechanical seals in back to back and nonpressurised buffer fluid for tandem seal Arrangement. The Barrier fluid enters the Thermosyphon Vessel, where it is cooled by water circulating through cooling coil to bring down the temperature of barrier fluid and back to the seal chamber. Thermosyphon arrangement is very effective. NOTE : Thermosyphon of higher pressure can also be designed if required. Alarm system can be supplied along with Thermosyphon on demand.

...more

Hand pump

Hand Pump Series – HP 100 Performance Limits HE -100 HE 200 Capacity: …………………………………. 1.5 Ltrs Operating Temperature…………… 80°C Design Pressure ……………………… 30 Kg Delivery Pressure…………….………. 25 Kg Displaced Volume …………………… 15cc/Stroke Connection Size Size …….……… ¼ ” NPT Hand Pump HP 100 is specially made for Thermosyphon Vessel. This is normally recommended for API Plan 53 or API Plan 54. The function of the Feed pump is to recharge the Thermosyphon Vessel with additional quantity of barrier fluid, when Thermosyphon is under pressure and Liquid level is low. This is caused due to mech.Seal failure or due to vapourisation

...more

Teflon Bellow Seal

Cartridge Seal

Double Cartridge Seals

Single Coil Spring Seals

Reactor Seal

Ceramic Sleeve

Industrial Compressor

merchant exporter services

Repair & Maintenance Services

Be first to Rate

Rate ThisOpening Hours