Frp Pressure Vessels

Get Price Quote

1 Set(s) (MOQ)

We are offering frp pressure vessels. frp pressure vessels are manufactured in various materials like pp + frp / pvc + frp / pvdf + frp / frp / frv etc. frp pressure vessels are designed as per client’s requirement depending upon capacity required / temperature of fluids to be stored , type of fluid / density /pressure / vacuum expected in vessel. these frp pressure vessels are manufactured normally with conical top and bottom or dish ends.

Vent Filter Vessel

4,855 Per Piece

Best Deals from Reaction Vessels

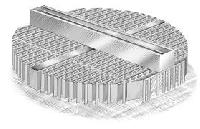

Structured Packings

Get Price Quote

Structured Packings is used where there is a requirement of azeotropic liquid separation. We have replaced conventional packings in a number of applications with our specially designed Structured Packings, radically altering the morphology of distillation, extraction and absorption systems. Structured Packings offered by us give optimum performance irrespective of the kind industry it is used at. We have a number of models in Structured Packings, each one tried and proven, developed and improved consistently by our technical team. As a reputed Manufacturer and Supplier of Structured Packings, we have satisfied our clients to the fullest. Not just this, we offer Structured Packings at reasonable prices. Range : Sheet based Structured Packings Wire-Web based Structured Packings Advantages : In comparison to Random Packings and Trays of Various types, Re-HI-TEK Packings offer following advantages : Higher Loading/Throughput of Columns, especially for larger diameter Columns. Lower Pressure Drop, especially for vacuum operations - Resulting in lower operating temperatures (important for heat sensitive materials). Low Packing Volume - especially for high number of stage requirement as in Isomers separation. Smaller hold-up Unchanged performance even at lower loadings Specifications PACKING CHARACTERISTICS "HI-PAK" TYPE Specific Surface Area: m2/m3 125 250 350 500 500 700 Voidage(%) 98.5 97.5 96.5 97 95 95.7 F-factor : m/sec (kg/m3)½ 1.0 - 3.0 0.8 - 2.5 1.0 - 2.5 2.0 - 2.5 0.6 - 1.8 1.5 - 2.0 1.8 Number of Stages /m ht. 01/01/05 02/05/03 02/04/12 05/08/12 3.8 - 4.2 07/12/12 Pressure Drop: Torr / m 0.2 - 2 0.4 - 3 2 - 4015 1 - 145 0.4 - 4 1 - 145

Plastic Crates

Get Price Quote

Offers plastic crates various range cap sizes 300 x 200 series 400 x 300 series 500 x 325 series 600 x 400 series 650 x 450 series 810 x 570 x 425 milk crates fruit and veg crates bread crates bottle crates.

PFA LINED VESSEL

Get Price Quote

SIZE RANGE: OD 250 MM X 2000 MMPLATE: IS 2062 GR. B OR A515 GR 60/70, OR AS PER CUSTOMER’S REQUIREMENT.COATING / LINING: PFA – D3307 TYPE II OR FEP D – 2116 TYPE IIISURFACE: External surface are painted with Red oxide primer.

PASTE PREPARATION VESSEL

Get Price Quote

Comes with 20 Ltrs to 250 Ltrs capacity. Basically this unit is used for preparation of starch paste. Hemispherical shape ensures that the heating of the starch paste is uniform and gets more surface area. The tilting type arrangement ensures ease in unloading the paste into any container or vessel. The starch is put in the kettle and water is added to it. The kettle is jacketed and is heated by steam/electrical till the starch melts and thick paste is achieved. The paste will be agitated with the help of an anchor type slow speed agitator which will constantly stir the paste so that there will not be any lumps formation and proper mixing is achieved. Mirror polished from inside and outside up to 240 Grit. Product temperature, measuring and controlling facility by means of TIC or PID control. Salient Features : cGMP Construction All contact parts of SS 316 grade Hemispherical bowl Bowl tilting by manual by worm and worm wheel Teflon scrapper for scrapping the paste Split, hinged top lid Excess pressure release valve on jacket for steam VFD for stirrer speed variation (Optional)

Order plug flow reactor

Get Price Quote

In the chemical industry whenever an exothermic or explosive reaction is needed to be carried out through the conventional way then in that case Their manufactured Plug Flow Reactor is widely utilized. They also ensure the safety of the equipments beside the uniform heat transfer. Our manufactured compact reactor possesses all the characteristics of heat transfer, static mixing and reaction engineering.

Steam Jacketed Vessel

Get Price Quote

1 Piece(s) (MOQ)

We are offering steam jacketed vessel. Make solid and liquid preparations in bulk with equal ease. Extra heavy double walled stainless steel steam vessel perfectly designed. Low energy cost, high performance and without burning or scorching, most hygienically

Limpet Coil

Get Price Quote

Limpet Coil Supported ourselves with proficient amenities, we are readily instrumental in providing an inclusive variety of Limpet Coil. Features : Specifically designed Long lasting Reliable High finish Ruggedness Less maintenance Raw material used : Carbon steel Stainless steel Low alloy steel Incoloy Inconel Clad

Pressure Vessel

Get Price Quote

A Pressure Vessel is a closed container designed to hold gases or liquids at a pressure different from the ambient pressure. These are used almost in all industries like chemicals, petrochemicals, refineries, pharmaseuticals etc.

Mobile Air Operated Perfume Mixing Vessel

Get Price Quote

We are offering mobile air operated perfume mixing vessel , machine application : 1) perfume mixing 2) low viscous liquid mixing 3) non foaming liquid mixing 4) liquid mixing 5) oil mixing machine operationdescription transfer liquid in the vessel required for mixing using the swastik's perfume transfer system. After all liquid is in the vessel give air supply to the vessel via prefitted frl. Switch on the air supply. The air operated agitator will start agitating the liquid in the vessel. Regulate the air pressure as required to change the speed of the agitator. After agitation is complete switch off the air supply. Transfer the liquid into the swastik's storage vessel for maturation or filling process. The vessel can be cleaned using swastik’s mobile cip system or manually. machine features : 1) large man hole for easy access 2) belly handle for easy maneuvering 3) lockable pu wheels 4) outlet valve provided 5) pre-fitted frl 6) variable speed 7) extra coupling for cip spray nozzle integration.

Pressure Vessel

Get Price Quote

Wide range of pressure vessels, high pressure or low pressure is designed and fabricated by NOVA. Also, wide range of materials such as carbon steel, stain steel and aluminum steel is available as demanded.The pressure vessels will be welded by only qualified welders who has passed examination of classification society or government authority according to qualified welding procedure specifications. All the pressure vessels are finalized by me of hydraulic test according to our quality management system. Available M.O. : S.S. 304, S.S. 316 etc. Capacities : 2 Ltrs. To 5000 Ltrs.

Pressure Vessels

Get Price Quote

PRESSURE VESSELS IN A WIDE RANGE CAPACITIES AND PRESSURES DC constructs stirred reactors and pressure vessels from most machinable alloys. Capacities range from 50 cc to 500 gallons (2 m3). Agitated reactor design pressures range from full vacuum to 150,000 psig (10,300 barg). Temperatures range from -400 °F to 2,500 °F ( -200 °C to 1,400 °C). Each stirred reactor is a complete system. This includes the reactor vessel, supporting stand, agitation assembly (magnetic stirrer, drive motor, belt, belt guard, impeller and digital tachometer), multiple process connections, drain, sample tube, temperature sensor, cooling coil and rupture disc assembly. Heating system and controls are optional. We offer a complete skid mounted stirred reactor system complete with product loading, feed, reaction and receiving modules, mass balance and product analysis. We also offer a variety of controls from simple manual controls to advanced PC-based SCADA and DCS. Please refer to our pilot plant section for additional information. Interested in a quote on a PDC stirred reactor? Please use our Stirred Reactor and Pressure Vessel Selection Guide to help you specify your stirred reactor or pressure vessel. INSTRUMENTATION AND CONTROLS PDC Machines supplies advanced instrumentation and control packages providing precise data acquisition to automatically record and manipulate multiple process parameters such as data logging, alarm monitoring, real-time and historical trending. These features are essential for predictable and repeatable process performance and scale-up. Our control packages are designed to be easily re-configured for flexibility and to adapt to developments in new technology. We combine the talents of process consultants, instrumentation and controls experts from various sources including Honeywell, Allen Bradley, Rosemont, Fisher, Siemens, Wonderware®, Intellution®, Cimplicity®, Think & Do®, LabVIEW®, and RSView® to name just a few. OUR CLIENTS Our clients include: • Air Products and Chemicals • Chevron Phillips Chemical Co • Akzo Nobel Chemicals • Celanese Chemicals • Bayer Corp • Cook Composites & Polymers • he Dow Chemical Co • E.I. Du Pont • Engelhard Corp • ExxonMobil Chemical Co • General Electric Corporate R&D • Omnova Solutions • International Specialty Products • Penford Products Co • Rohm & Haas • PQ Corp • Sartomar Co • Witco Chemical Corp. • Saudi Arabia Basic Industries (SABIC) • W.L. Gore & Associates

Starch Paste Manufacturing Vessel

Get Price Quote

Starch Paste Kettle will be made out of S.S. 304 Rectangular Pipes and will be an independent resting type frame work where no foundation will be required. The Kettle will be a hemispherical type bowl with either steam / Oil / Water heating Jacket will be provided. The Kettle will be manufactured from 2.5 mm thick S.S. 304 Sheet and The Jacket will be of 2.5 mm Mild Steel (In case of steam Jacket the thickness will be 4 mm) There will be oil / water heated fitted at the back bottom side of the Kettle. The Kettle Will be having a worm type arrangement for tilting. A temperature controller & a temp Indicator will be provided for temp control & Indication. The Kettle will be Insulated with 50 Mm thick glass wool

Pressure Vessels

Get Price Quote

Made out of 16 gauges AISI 316 complete with ring cover, wing nuts and neoprene gasket. Bent out-let nozzle will be fitted with S. S. Pipe to draw out all the fluid from the vessel. Inlet nozzle for allowing pressurized air. This vessels are tested at 4 bar pressure , conical in shape at top.

Spiral PP Chemical Reaction Vessel

Get Price Quote

1 Piece(s) (MOQ)

Inhealer manufacturing vessel

Get Price Quote

TECHNICAL SPECIFICATION : Vessel design as per ASME SEC-VIII, DIV-I Pressure vessel with Agitator. Zero dead legs valve for outlet. Rapture disc for pressure safety. Mechanical seal for stirrer to withstand high pressure. Special design hopper for Powder charging. Pneumatical operated lifting arrangement. Special gasket / “O” Ring compatible with product. Complete FLP design. OPERATION : Complete manual operation with FLP Panel (Auto – Operation on demand.) FEATURES : Minimum stirring agitator with high pressure.Vessel is CIP / SIP able.

Process Reactor

Get Price Quote

Limpet Reactor

300 Per Piece

90 Piece(s) (MOQ)

We are offering limpet reactor with drive rotary equip pvt ltd manufacture highly efficient limpeted reactors available in several designs including electrical, hot oil and steam heated. The product is widely used in various industries like medical, building material, chemical, paint, resin, food ect industries. It receives appreciation from our global clients for its easy operation, study construction, leak proof and durability. Using quality material like stainless steel such as ss 304, ss 316, and m.s, product is durable and has long service life. They are crack resistant and have leakage proof features having a high range of capacity. With limpet coil,and double limpet coil with approved inception agencies like tuv, bvis and as per client needs.

JACKETED PRESSURE VESSEL MACHINE

Get Price Quote