Get Price Quote

EPS Recycle Granules, GPPS CLEAR SHEET, MMA Resins, plastic regrind

Pharmaceutical Mixing Vessels

25,000 - 35,000 Per Piece

1 Piece (MOQ)

Best Deals from Reaction Vessels

Dissolution Clear Glass Vessel

900 - 1,200 Per Piece

1 Set(s) (MOQ)

We are the manufacturers and supplier of this products.

Air Pressure Vessel

Get Price Quote

1 Piece (MOQ)

Conical Reaction Vessels

Get Price Quote

Holding the know-how and expertise achieved over the years, we offer Conical Reaction Vessels. They are available in a number of specifications. Thanks to our competent professionals, recent technology and latest machines, we manufacture the best quality. The raw material which is used in manufacturing process is purchased from dependable vendors who refuse to compromise with quality. The supreme quality renders them admired among customers. Details : We manufacture bottom conical Reaction Vessel from 50 Ltrs to 30 KL in Mild Steel, Stainless Steel SS 304 or SS 316. conical Reaction Vessel consist of a Cylindrical vertical shell with Top dish end & bottom conical with body flange on top dish. A Jacket or Limpet coil is provided on the shell and is similar to Jacketed or Limpet Coil Reactor except there is top dish with drive system. The drive is designed to give maintenance and trouble free performance. The Agitator Shaft is coupled to the Reduction Gear Box with Flexible coupling. The Reduction Gear Box is mounted on the Top of the Lantern Assembly and is driven by Motor using V belt pulley. Variator or AC drive can by used to get variable speed of the Agitator if desired. Four lugs support are provided on the Shell of the reactor to mount it on the Platform of the Factory. Platform can also be prefabricated and assembled at site.

Limpet Coil Reactor Vessel

200,000 - 4,000,000 Per Piece

1 Piece (MOQ)

Capacity: 500 Ltr. 1000 Ltr., 2000 Ltr. 3000 Ltr. 4000 Ltr. 5000 Ltr. 6000 Ltr. 7000 Ltr. 8000 Ltr. 9000 Ltr. 10000 Ltr. 110000 Ltr. 120000 Ltr. 130000 Ltr. 140000 Ltr. 150000 Ltr. 160000 Ltr. 170000 Ltr. 180000 Ltr. 190000 Ltr. 200000 Ltr. 210000 Ltr. 220000 Ltr. 230000 Ltr. 240000 Ltr. 250000 Ltr.

Vessels

Get Price Quote

Our Columns and Tanks are fabricated as,Solid metal Cladded metal Lined Our Columns & Tanks are fabricated from exotic material like, Titanium, Tantalum, Zirconium,Nickel, Monel, Inconel, Duplex & Super Duplex and Special grades of Stainless SteelApplications of TowerStripper columnsDistillation columnsDrying columnsAbsorption towersLeach vesselEmergency scrubber Absorbing tower Venturi scrubber Knock out drumApplication & Storage Types of TanksAnolyte & Catholyte tanksChemical Storage tanksMixing tankCorrosive liquid storage tankVertical storage tankCone bottom tank Cladded tank Custom fabricated tanks Metal lined tankRubber lined storage tanks

Limpet Reactor

Get Price Quote

1 Piece (MOQ)

Graphite Lined Reactor

Get Price Quote

Our company is the manufacturer of highly efficient Graphite Lined Reactor in Mumbai. As a reliable supplier of Graphite Lined Reactor in Mumbai, we are bringing forth wide range of Graphite Lined Reactors used for various chemical reaction in industries like heavy chemicals, pharmaceuticals, Food & Drug, Dye and pigment, Paints, Adhesive, color, concrete related chemicals where corrosive problems are prevalent. Our offered products posses the following features: Excellent corrosion prevention against wide range of corrosive chemicals Excellent heat transfer from jacket to vessel & vice versa, hence heating and cooling can be done Easy for maintenance Long life (Operation vise) compared to glass line reactors Good abrasion resistant Good thermal shock Resistance Graphite lining is possible to any small tank of 0.5 KL capacity upto 100 KL capacity, with Agitators, stirrers, Baffles, Nozzles & Manholes

Stainless Steel Pressure Vessel

92,500 Per Piece

1 Piece (MOQ)

Vinay is one of the leading manufacturer, supplier and exporter of superior quality Stainless steel pressure vessel in different types, various sizes, and grade qualities. A Stainless steel pressure vessel is a superior grade high pressure vessel that enables the sterilization of pressure vessel in high pressures after each batch is moved and the process of next batches, thereby removing the risk of bacteriological growth. Stainless steel pressure vessel used in the Pharma, Biotech, Chemical sectors to handle drugs, ointments and, food/drinks. Vinay's Stainless steel pressure vessel is made of superior grade stainless steel which is resistant to corrosion, chemical abrasion and also easy to use and handle as all its parts are welded by Argon welding. Its welldesigned look gives elegant and aesthetic finish. Vinay's Stainless steel pressure vessel is 100% quality checked and tested since it is manufactured by the latest well-equipped CNC machinery and latest techniques like cutting and bending and for any other structural flaws by our highly qualified professional staff according to Indian and international industry standards guidelines. At Vinay, by using cutting edge industrial manufacturing methods and quality controls through production sections we confirm that customers get prime Stainless steel pressure vessel custom-made to client's requirements. Each pharmaceutical product is developed as per the ISO standards and pharmaceutically is safe and hygienic. Features: Aesthetic look, Corrosion-free, Precision made, Highly durable, Easily Washable, Easily cleanable, Cost-effective

PP FRP Reactor

150,000 - 500,000 Per piece

10 piece (MOQ)

MOLEX Industrial Receptacles 1300130493

2,600 - 13,000 Per Piece

brad mini-change connectors molex industrial receptacles 1300130493 description: mini-change a-size receptacle, 5 poles, 1/2" - 14 npt threads, male (straight) to 16 awg leads, zinc die-cast with black epoxy, 0.305m (1.0') length

ss316 storage vessels

Get Price Quote

Being an illustrious Supplier of ss316 storage vessels, we endeavor to achieve 100% customer satisfaction. Place orders with us, timely deliveries of the same are our prime responsibility!

Reaction Vessels

Get Price Quote

FRP, PP+FRP, PVDF+FRP, PVC+FRP Reaction vessels in any capacity. Cylindrical vertical and conical bottom/dish or flat type.

Titanium Vessel Reactor for Gold and Silver

Get Price Quote

1 Piece (MOQ)

Chemical Reactor

Get Price Quote

Chemical reactors are vessels designed to contain chemical reactions. One example is a pressure reactor. The design of a chemical reactor deals with multiple aspects of chemical engineering. Chemical engineers design reactors to maximize net present value for the given reaction.Designers ensure that the reaction proceeds with the highest efficiency towards the desired output product, producing the highest yield of product while requiring the least amount of money to purchase and operate. Normal operating expenses include energy input, energy removal, raw material costs, labor, etc. Energy changes can come in the form of heating or cooling, pumping to increase pressure, frictional pressure loss (such as pressure drop across a 90° elbow or an orifice plate), agitation, etc.

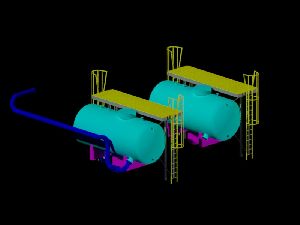

Pressure Vessels

Get Price Quote

Kerone has won a reputation for impeccable quality and total reliability in the design and manufacture of pressure vessels, Columns and Shell & Tube Heat Exchangers, These Equipments are designed by experienced staff using latest software and as per international standards like ASME, PD 5500, Rules 1981, IBR (Indian Boiler Regulation 1950), API 650 or as per customer requirement. A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. The pressure differential is dangerous and fatal accidents have occurred in the history of pressure vessel development and operation. Consequently, pressure vessel design, manufacture, and operation are regulated by engineering authorities backed by legislation. For these reasons, the definition of a pressure vessel varies from country to country, but involves parameters such as maximum safe operating pressure and temperature. Pressure vessels are used in a variety of applications in both industry and the private sector. They appear in these sectors as industrial compressed air receivers and domestic hot water storage tanks. Other examples of pressure vessels are diving cylinders, recompression chambers, distillation towers, pressure reactors, autoclaves, and many other vessels in mining operations, oil refineries and petrochemical plants, nuclear reactor vessels, submarine and space ship habitats, pneumatic reservoirs, hydraulic reservoirs under pressure, rail vehicle airbrake reservoirs, road vehicle airbrake reservoirs, and storage vessels for liquefied gases such as ammonia, chlorine, propane, butane, and LPG.

Frp Pressure Vessel

Get Price Quote

Manufactured cylindrical vertical tankhorizontal tanks with flat and dish ends as per required process conditions and generally square and rectangular tanks are preferred for the bulk storage of corossive liquid. As per the floor area provided size and shape of the tanks are designed.

Non Stirred High Pressure Vessels

Get Price Quote

Salient Features 25 ml to 100 ltr net filling volume standard models & 150 ltr to 2000 ltr customized solutions Pressures upto 700 bar & temperatures upto 600°C Available in different Materials of Construction (MOC) like SS-316, SS-316L, Hastelloy B/C, Monel, Nickel, Inconel, Titanium, Tantalum, Tantalum lined, Zirconium etc. Ex-proof / ATEX / CE / PED / ASME U / U2 / CRN certified systems on request Fully automated PC controlled high pressure system / pilot plant to continuously monitor, control & record various parameters Applications For gas / liquid storage / charging under pressure For gas / liquid separation & collection For static, loop, electrochemical, corrosion studies For study of gas hydrate formation For supercritical fluid extraction For hydrogen induced disbonding tests For soaking of diamonds / precious stones

Pressure Vessel

3,828 - 200,000 Per Piece

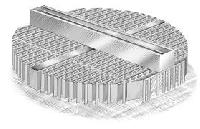

Structured Packings

Get Price Quote

Structured Packings is used where there is a requirement of azeotropic liquid separation. We have replaced conventional packings in a number of applications with our specially designed Structured Packings, radically altering the morphology of distillation, extraction and absorption systems. Structured Packings offered by us give optimum performance irrespective of the kind industry it is used at. We have a number of models in Structured Packings, each one tried and proven, developed and improved consistently by our technical team. As a reputed Manufacturer and Supplier of Structured Packings, we have satisfied our clients to the fullest. Not just this, we offer Structured Packings at reasonable prices. Range : Sheet based Structured Packings Wire-Web based Structured Packings Advantages : In comparison to Random Packings and Trays of Various types, Re-HI-TEK Packings offer following advantages : Higher Loading/Throughput of Columns, especially for larger diameter Columns. Lower Pressure Drop, especially for vacuum operations - Resulting in lower operating temperatures (important for heat sensitive materials). Low Packing Volume - especially for high number of stage requirement as in Isomers separation. Smaller hold-up Unchanged performance even at lower loadings Specifications PACKING CHARACTERISTICS "HI-PAK" TYPE Specific Surface Area: m2/m3 125 250 350 500 500 700 Voidage(%) 98.5 97.5 96.5 97 95 95.7 F-factor : m/sec (kg/m3)½ 1.0 - 3.0 0.8 - 2.5 1.0 - 2.5 2.0 - 2.5 0.6 - 1.8 1.5 - 2.0 1.8 Number of Stages /m ht. 01/01/05 02/05/03 02/04/12 05/08/12 3.8 - 4.2 07/12/12 Pressure Drop: Torr / m 0.2 - 2 0.4 - 3 2 - 4015 1 - 145 0.4 - 4 1 - 145

Ointment and Cream Vessel

Get Price Quote

Backed by a well-organized and structured storage unit, we efficiently store the entire array of products in a secured manner. Furthermore, we ensure total security of the products. With our years of experience, our company name figures amidst the most responsive and responsible Suppliers of Ointment and Cream Vessel. Approx Price : Rs 1 Lakh / Piece(s) Supported ourselves with proficient amenities, we are readily instrumental in providing CO Mill. Features: Specifically designed Long lasting Maintenance-free Sturdy Co Mill is used for Dry and Wet milling/size reduction of wide range of products. It is suitable for stand alone as well as online milling. Benefits & Highlights Low speed design allowing for inherently gentle action on the product resulting in optimum particle granularity, low heat, low noise, minimal fines, consistent, high quality end product, can be used on heat sensitive products, high capacities, fully customizable to many different applications and process stream. Advantages as compared to other Milling Equipment : The Output in Co Mill is very near to the size of the sieve used approx. 80% - 90% where as in Multi Mill it is 1/3 of the sieve used The Fines generated are on a lower side as compared to other mills Heat generation in Co Mill is comparatively very low as it works on forced pressure Other Mills have more of dusting as compared to Co Mill Output in Co Mill is more than any other mills Design is flexible as per your requirement.

Insulated Tank Vessel

500,000 Per Piece

Frp Vessels

Get Price Quote

We are a Company providing end-to-end solutions in water purification, treatment ,Conservation and Management since last 15 Years. FRP vessels available in varous sizes and capacities.Top and Bottom opening in 212 inches and 4 inches.For more details send me an enquiry on email or call me

Continuous Stirred Tank Reactor

Get Price Quote

PP Reaction Vessel

Get Price Quote

Pressure Vessels

Get Price Quote

1 Ton (MOQ)

Pilot Single Vessel

Get Price Quote

* Hydraulic lifting for vessel * Top / bottom homogeniser * Dual anchor agitator with fix anchor

Plastic Crates

Get Price Quote

Offers plastic crates various range cap sizes 300 x 200 series 400 x 300 series 500 x 325 series 600 x 400 series 650 x 450 series 810 x 570 x 425 milk crates fruit and veg crates bread crates bottle crates.

Wheel Mounted Vessel

Get Price Quote

Wheel Mounted Vessels Description / Specification of Wheel Mounted Vessels We are involved in offering a wide range of Wheel Mounted Vessels to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.We introduce ourselves as an eminent trader and supplier of an extensive array of Wheel Mounted Vessels. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.Features: Sturdy design Highly durable Application specific design