Water Recycling Plant

Get Price Quote

1 Piece (MOQ)

Granulator Recycling Shredder Machine

300,000 - 500,000 Per Piece

1 Piece (MOQ)

In today's world, waste management and recycling are critical for sustainable development. One of the key players in this process is the Granulator Recycling Shredder Machine. This powerful machine, such as those manufactured by SHREDALL, plays a pivotal role in recycling various waste materials, turning them into reusable products. A Granulator Recycling Shredder Machine, like the ones from SHREDALL, is a robust piece of equipment used in the recycling industry. It's designed to shred, crush, and granulate waste materials into smaller, manageable sizes. These machines are commonly used for processing materials such as plastic, metal, rubber, and paper. The Working of Granulator Recycling Shredder The working principle of a SHREDALL Granulator Recycling Shredder Machine involves a two-step process: shredding and granulating. Initially, the waste material is fed into the shredder, which reduces the material into smaller pieces. These shredded pieces are then transferred to the granulator, where they are further processed into tiny granules ready for recycling. Key Features Recycling not only benefits the environment but also has economic advantages. The materials processed by these machines can be sold to manufacturing industries, creating a profitable recycling business. Shredding Material The SHREDALL Granulator Recycling Shredder Machine efficiently processes various materials like plastic, metal, rubber, and paper. Its robust design and two-step process make it a key player in waste management and recycling. Shredding Machine Type The SHREDALL Granulator Recycling Shredder Machine, for instance, is an industrial shredder capable of processing a variety of materials for recycling purposes. It’s a robust and versatile machine, Dual Shaft, making it a valuable asset in waste management and recycling. Usage/Application The SHREDALL Granulator Recycling Shredder Machine is widely used in various sectors for its versatility. Its primary application is in waste management and recycling facilities, manufacturing industries to recycle waste materials into reusable resources, contributing to economic benefits and environmental sustainability. Capacity With a shredder from 100 kgs/hr to 500 kgs/hr, the machine is available for small, medium to large-scale operations. Automation Grade The Shredder Machine is fully automatic, which makes it easy to operate. Motor Power The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance. Country of Origin Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess. High Performance and Easy Installation The SHREDALLGranulator Recycling Shredder Machine is known for its high performance. It efficiently processes a variety of materials, ensuring optimal waste management and recycling. Despite its robust capabilities, the machine is designed for easy installation. This combination of high performance and ease of installation makes it a preferred choice in various sectors. Product Description The SHREDALL Granulator Recycling Shredder Machine is a high-performance, easy-to-install recycling solution. It’s designed to process a variety of materials, including plastic, metal, rubber, and paper, into smaller, manageable sizes. This robust machine is widely used in waste management and recycling facilities, contributing to environmental sustainability and economic benefits. Its efficient operation and easy installation make it a valuable asset in various sectors. Contact Us We are here to assist you. Feel free to contact us: Email: info@shredall.in +91 9820020754 Conclusion The SHREDALLGranulator Recycling Shredder Machine is a vital tool in our quest for a more sustainable future. Its ability to efficiently process waste materials into reusable resources makes it an invaluable asset in the recycling industry.

Best Deals from Recycling Plant

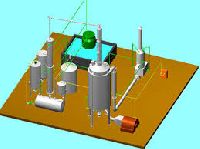

Recycling Plant

Get Price Quote

Plant suitable for recycling application. Wide range to meet various throughput requirement. Compact and modular design. Water ring type horizontal die face cutter. S.S. Water tank & turbo dryer housing & impeller. Vapour extractor on turbo dryer for dry granules. Vented extruder for ABS Resins. Hopper loader & hopper dryer (optional). AC Drives for extruder (optional). Digital temperature controllers. Hydraulic screen changer for higher output plants. Granule conveying & storage system (optional).

Plastic Recycling Plant

Get Price Quote

Recycling Line with Japanese Technology Developed for Plasticizing & Recycling of LDHDHMHDPP PS FilmBOPPPP Film Machine suitable to process materials in the form of MonoMultilayer Film Waste Highly Printed Film Waste Metalized Non – Metalized BOPP-CPP All the Oriental Product – MonofilamentMulti Filament Non-WovenWoven or Tape or Raffi

Lube Oil Re Refining Plant

Get Price Quote

Double Extruder Plastic Recycling Plant

Get Price Quote

1 Piece (MOQ)

Lead Recycling Plant

Get Price Quote

Lead Acid Battery Recycling Plant

1,500,000 - 25,000,000 Per Set

1 Set(s) (MOQ)

Plastic Recycling Machine

1,650,000 - 1,800,000 Per Set

Waste Carton Paper Recycling Machine

Get Price Quote

Plastic Recycling Machine

Get Price Quote

Plastic Recycling Machine with Gas Nitrated Screw & Barrel made out of high quality alloy steel duly hardened & ground for longer life & better output. Features: With reputed make gearbox & motor. Plastic Recycling Machine with separate control panel provided with temperature controller & all the necessary controls for reprocessing various grades of thermoplastics. With water tank with stand provided for cooling purpose. For LDPE, HDPE, PP, PS, HIPS, ABS, Nylon, PET, PVC material. For reprocessing of plastic waste materials containing high moisture level is possible without problems. With reduced screw and barrel wear minimise damage to processed material. With simple, robust design minimal thermal damage to the reprocessed material. Which produces uniform pallets. With Low noise emission. With very attractive cost/benefit ratio. With Low-key service and maintenance.

glass recycling

Get Price Quote

Dealing in recycled glass both in amber & white colour arrange recycled glass on request . Customer satisfaction is our main goal.

PET Bottle Recycle

Get Price Quote

Plasticrafts (India) manufactured India’s first mini scrap granulator which was successfully installed at Inorbit mall, Vashi, Mumbai to granulate used PET bottles for the BISLERI. India’s 1st custom made granulator which was made available to consumers to discard and recycle used PET bottles. Saving space instantly due to Particle Size Reduction , it also enables recycling at the point of consumption. Larger production and higher output granulators are also available. Details as per requirement can be provided on request.

Plastic Recycling Plant

750,000 Per Piece

Plastic Recycling Plant

Get Price Quote

We are among the most distinguished Manufacturers, Suppliers and Exporters of Plastic Recycling Plants. With the growing concerns of environmental issues, recycling of resources is a smart way to conserve them. Our Plastic Recycling Plants are designed in such a way that there is no wastage what so ever. All the plastic scrap is collected and fed into the plant. The recycled Plastic can then be molded into a number of useful forms. Merits Of Plastic Recycling Plants High PerformanceEasy InstallationSimple OperationHigh EfficiencyEconomical

recycling machine

Get Price Quote

Model screw dia.(mm) connected load (kw) output (kgh) raj-65rpdfc 65 24 50-60 raj-75rpdfc 75 34 80-100 raj-90rpdfc 90 48 120-140 raj-100rpdfc 100 65 180-200 raj-120rpdfc 120 105 230-260 raj-150rpdfc 150 140 330-360.

Solid Waste Recycling Machine

Get Price Quote

We are offering solid waste recycling machine.

concrete recycling plant

Get Price Quote

Since then, our systems have proved to be reliable, economical and highly wear-resistant. Our permanent development efforts have made the Stetter concrete recycling plant an exceptionally strong product. We now offer two different sizes – from 12m3 h to a maximum of 20m3 h concrete recycling.

Slag Recycling Machine

Get Price Quote

Recycling is today concern as every penny saved is penny earned.For a 10 Ton Induction furnace producing around 100 TPD, the slag generation is around 6% to 10% of total production depending on the quality and type of scrap. Say 6% of slag, that is 6T of slag is generated per day, monthly generation of slag with an average of 26 working days is 168 Tons. per month. As per our experiments and finding through visits to various steel plants around the country there is 5% to 6% steel content in the slag after manually retrieving visible steel scrap from the slag 6% of 168 Ton of Slag generation is 10T and the cost of Steel Scrap recovered @ Rs17/- per Kg is Rs.1,70,000/- per month. For an Induction Furnace of Capacity 10T per batch. Production Per day - 100 TPD* Slag generation @ 6 % - 6 TPD* Slag generated per month. - 168 TPM+ 5% Steel Scrap Retrieved from Slag - 10 TPM+ * TPD = Tons Per Day + TPM = Tons Per Month

Waste Oil Recycling Equipment

Get Price Quote

DMAC is an indigenous PETROF technology for refining of used lube oil products. Some of its astute characteristics are: DMAC uses No Hazardous or Banned chemicals. DMAC removes Halogens,heavy metals, Sulfur and oxidized products and bring them withinpermissible limits. DMAC yields high quality base stock with better Color and Oxidation Stability with ZERO CLAY. DMAC Save Complete process Energy Consumption by 30%, as compared to other Processes. DMAC Prevents equipment fouling, corrosion, and coking ofprocess equipment such as heat exchangers and vacuum system. DMAC process separates bottom from feedstock which can be used as asphalt extender, rubber process oil, base for black printing ink, axle grease manufacturing and as rust proofing compound.

Recycling Extruder Machine

Get Price Quote

Pelletiser Reprocessing Plant

400,000 Per Piece

Plastic Recycling Machines

Get Price Quote

waste paper recycling plant

Get Price Quote

waste paper recycling plant Our supplies are sourced from over five continents. Our client list is extensive, ranging from smallmedium size to large scale factories in India.

pet recycling machine

Get Price Quote

Horizontal spin drier gravity separator bottle washer hot wash reactors pn drier zig zag machine label remover.

plastic bottle recycling machine

250,000 Per Piece

1 Piece (MOQ)

Palletizing-&-Recycling

Get Price Quote

Application Palletizing of Plastics Standard Palletizing of Plastics Various as per Machines like Erema, Brengier, etc.

Wastewater Recycling Equipment

Get Price Quote

Wastewater Recycling Equipment which has developed a breakthrough water waste stream clean up technology for land based application and other water-intensive industries.Unlike other technologies, the company’s patent-pending process rapidly and efficiently removesseparate organic material from large quantities of water without the need for chemicals.

Cotton Waste Recycling Machine

Get Price Quote