polyester resin plant

Get Price Quote

1 Piece (MOQ)

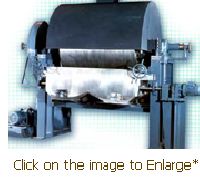

Rotary Drum Flaker

Get Price Quote

Flakers are used for solidifying molten material. After processing on flakers, the material forms films or easily handled flakes and is further processed or packed into containers for transport. A great advantage of flakers is that they offer a continuous process. The hot material is applied to the cooling drum by direct immersion into a trough, or indirect immersion using doctor/applicator rolls. The molten liquid is cooled on the cooling drum and after a partial revolution; the cooled and solidified product is removed by a scraper in the form of flakes or film.We manufacture, design and develop optimum quality rotary drum flakers. Our range of drum flakers is available in single drum flakers, double drum flakers.Material of Construction (MOC) Offered :- CS (IS 2062 Gr A/B, SA 516 Gr 60/70, BQ), SS 316, SS 304, SS 316 L, SS 304 L. SS 310, MONEL, INCONEL, TITANIUM, HASTALLOY, PP/FRP ETC.Special Features : Designed for trouble free operation Low Cost operation Continuous Process High thermal efficiency Minimum thermal degradation Accomplishment of flaking in a single step Uniformly flaked product

Best Deals from Resin Manufacturing Plant

Drum Flaker

Get Price Quote

Special applications include single drum, double drum, twin drum and custom flaker.

Solvent Based Resin Plant

Get Price Quote

Owing to our commitment to quality, we bring forth efficient Solvent Based Resin Plant. The Solvent Based Resin Plant is innovatively conceptualized and designed by our engineers for the processing of Solvent Based Resins. Further, our Solvent Based Resin Plant is capable enough to facilitate fast and efficient process. Highlights : Easy to operate Robust construction Efficient performance High Solvent Based Resin output

Unsaturated Polyester Resin Plant

750,000 Per Set

1 Set(s) (MOQ)

Grease Plant

Get Price Quote

we are major manufacturer and supplier of Gel Grease in Mumbai, India. The Gel Grease manufactured is step by step processed under the supervision by our adroit professionals. It is manufactured at our plant with the state of art machinery & infrastructure, our production unit comprises of technicians, supervisor and Managers. The raw material is source from certified vendors and is as per set industry norms. This grease is highly appreciated among the clients due to its purity, stability, accurate composition and longer shelf life. Being a customer centric organization, we are highly engrossed in offering premium quality Gel Grease in different packaging options. Moreover, used as a excellent lubricant, this grease is available to the clients at reasonable rates.

polyester resin plant

1,000,000 - 2,000,000 Per Pi1ece

01 Piece (MOQ)

Drum Flakers

500,000 - 5,000,000 Per Piece

1 Piece(s) (MOQ)

We make drum flakers for all industries . Production rate 50 kgs to 5000 kgs per hr

GREASE PLANTS

Get Price Quote

Grease is a fine dispersion of an oil-insoluble thickening agent - usually soap in a fluid lubricant which is generally mineral lubricating oil. The soap is made up of fatty acid, tallow or vegetable oil saponified with alkali which can be hydrated lime, caustic soda, lithium hydroxide or aluminum hydroxide. The lubricating oil component is refined base oil-naphthenic, of medium viscosity index, or cylinder oil stock.Structurally grease is a “water-in-oil” emulsion. Its appearance is smooth, mostly translucent, soft or hard.Properties essential for performance of grease are structural stability, lubricating quality, low and high temperature performance (which are provided by the selected lube oil base stock), where as properties such as water resistance, high temperature quality, resistance to break down through continuous use and ability of grease to stay in place are provided by the soap.Additives eg. Graphite, modified clay, asphalt, oxidation and corrosion inhibitors, extreme pressure additives melybdenum disulphide etc. are used to impart specific properties as required by end application. UNIT PROCESSES AND UNIT EQUIPMENT IN GREASE MANUFACTURING. 1. Pumping of raw material from storage tanks into day tanks 2. Raw materials measurement by volume or weight using weighing scales, meters, tank gauges etc.3. Preparing the soap by heating and premixing fat and lube oil in kettles with counter rotating scraper stirrer operated by motor and reduction gear.4. Cooling of the prepared soap and balancing with oil to prepare grease in a cooling kettle.5. Formation of grease structure by dispersion in a milling machine under controlled moisture and temperature parameters.6. Deareation using deareator.7. Filtering through filter.8. Filling using weigh scales/ filling machines.9. Instrumentation - indicators/recorders for temperature and pressure.10. Pumps- gear and centrifugal for lube oils, vegetables oils, liquid soap and grease at various stages of manufacturing.11. Material handling equipment like hoist, pallet trucks, and fork lifts to handle solid fats, additives, alkali, drums etc.12. Safety and fire protection devices.13. Lab equipment14. Utilities like hot oil system, cooling system, air compressor, water etc

Rotary Drum Flaker

Get Price Quote

We offer the rotary drum flaker as below, rotary drum flaker salient features :- • continuous type dryers and coolers • suitable for solid separations from liquids without filtration operation • bigger solid particles flakers • suitable for sticky materials, resins, snacks, food fine chemicals • direct air heated, hot water, steam or electric heater for more details please contact us.

SILICONE RESIN PLANT

Get Price Quote

We are engaged in manufacturing and exporting Chlorinated and Silicon Resin plants (multipurpose resin plant) for our clients spread worldwide. These are available in various technical specifications and are appreciated worldwide for its unique features such as high durability, corrosion resistance and optimum utility.In our range, we offer pilot plant, micron size filter, silicone resin, chlorinated resin, silicone resin plant and chlorinated resin plant.

Grease Plant

Get Price Quote

Types Of Greases Lithium, Calcium, Soda, Aluminium,Complex and Mixed soap base Greases, Soap free Grease, PTFE, Silicone and Molybdenum modified Greases, Specialty and Synthetic Greases. Basic Defination The original Definition of ASTM of Grease was "A solid or semi solid combination of petroleum products and a soap or mixtures of soaps with or without fillers, suitable for certain types of lubrication. Subsequent technological advances have led to the use of synthetic lubricating fluids on the one hand and non-soap thickeners on the other hand. Current - Modified Definition of Grease is "A solid or semi solid product of dispersion of thickening agent in liquid lubricant. Other ingredients imparting special properties may be included. Most greases are in fact is a combination of petroleum oils and metallic soaps. Grease is a lubricant of higher initial viscosity than oil, consisting originally of a calcium, sodium or lithium soap jelly emulsified with mineral oil. Greases are typically used in areas where a continuous supply of oil cannot be retained, such as open bearings or gears. Grease is a fine dispersion of an oil-insoluble thickening agent - usually soap in a fluid lubricant which is generally mineral lubricating oil. The soap is made up of fatty acid, tallow or vegetable oil saponified with alkali which can be hydrated lime, caustic soda, lithium hydroxide or aluminum hydroxide. The lubricating oil component is refined base oil-naphthenic, of medium viscosity index, or cylinder oil stock. Structurally grease is a water-in-oil emulsion. Its appearance is smooth, mostly translucent, soft or hard. Properties essential for performance of grease are structural stability, lubricating quality, low and high temperature performance (which are provided by the selected lube oil base stock), where as properties such as water resistance, high temperature quality, resistance to break down through continuous use and ability of grease to stay in place are provided by the soap. Additives e.g. Graphite, modified clay, asphalt, oxidation and corrosion inhibitors, extreme pressure additives molybdenum disulphide etc. are used to impart specific properties as required by end application. Factors to be considered when selecting greases are the type of grease, which in turn depends on operating temperatures, water resistance, oxidation stability etc. The second factor, no less important, are the grease's characteristics, including viscosity and consistency. The value of plastic lubricants has been recognized since very early times when animal fats were used for Axles and the like. In general any lubricating fluid can be gelled by means of a suitable thickness to form a lubricating Grease. In practice mineral oils are almost exclusively used. For soap type Greases mineral oils of relatively low viscosity index 60 are preferred since the greater solvency of the more aromatic oils for soaps makes manufacture easier and gives greases with lower soap contents and with better properties. Synthetic Fluids: Esters and silicones are used, only in greases for special applications, where cost is secondary to performance to meet low temperature and high temperature requirements; - 75C to + 320C. The Soaps used are the metallic salts of long chain fatty acids derived from wide range of natural fatty materials. Soaps are mainly produced by specifying the fat or fatty acid with appropriate alkali in the presence of oil. In some cases pre-formed soaps are used, such as aluminium stearate, lithium sterate etc. Non Soap Thickners may be inorganic e.g. silica or clay or organic with a very high melting point . e.g. terephthalamates, arylureas (these may be either pre-formed or formed in situ) and the dye stuffs, indanthrene and phthalscyanine. They need to be oleophilic and this characteristic may be imparted either in the thickner formulation (i.e. by including a long chain hydrocarbon chain or surface esterification ) or by coating the particle surfaces with organic cations. In the latter case about 75 percent of the particle surface is covered, which gives the desired effect without affecting inter particle forces too much. Pre-treated clays (i.e. coated and dried) need aids to facilitate dispersion in oil. These dispersion aids are low molecular weight polar organic compounds such as methanol, acetone, diacetone Alcohol and propylene Carbonate. A satisfactory Grease for a given application is expected to: Provide adequate lubrication to reduce friction and to prevent harmful wear of bearing components Protect against corrosion Act as a seal to prevent entry of dirt and water. Resist leakage dripping or undesirable throw off from the lubricated surfaces. Resit objectionable change in structure or consistency with mechanical working (in the bearing) during prolonged services. Not stiffen excessively to cause undue resistance to motion in cold weather. Have suitable physical characteristics for the method of application. Be compatible with elastomer seals and other materials of construction in the lubricated portion of the mechanism. Tolerate some deqree of contamination, such as moisture, without loss of significant characteristics. Soap Greases consist of dispersions of soap fibres in oil in concentrations mostly in the range 5 to 22%. By weight sometimes solid block greases contain 50 to 40% of soap. The thickeners in non-soap greases are usually particulate rather than fibrous in nature and in this case the structure is maintained by 3 dimensional linkages due to very short range inter particle forces (Vander waals forces). These linkages are readily broken and re-formed. Types Of Greases The metallic radical of the soap largely determines the characteristics of the greases the fatty radical having a secondary effect. Greases are therefore classified in terms of the metal they contain.

Grease Plant

Get Price Quote

The original Definition of ASTM of Grease was "A” solid or semi solid combination of petroleum products and a soap or mixtures of soaps with or without fillers, suitable for certain types of lubrication. Subsequent technological advances have led to the use of synthetic lubricating fluids on the one hand and non-soap thickener’s on the other hand. Current - Modified Definition of Grease is "A solid or semi solid product of dispersion of thickening agent in liquid lubricant. Other ingredients imparting special properties may be included”. Most greases are in fact is a combination of petroleum oils and metallic soaps.

resin pilot plant

Get Price Quote

Drum Flaker

Get Price Quote

The Pragati Enginnering Works offers flaker, industrial flaker, chemical flaker, flaker machines to convert molten chemical in to solid flakes. This is achieved by forming a thin layer of molten product on the outside surface of a rotating drum and causing this to be solidified by spraying cooling water from inside surface of the drum. An adjustable scrapper continuously removes the solidified from the drum surface in flake forms. The material of construction for the drum can be mild steel,Stainless Steel with with Hard Chrome Plating, normally Monoblock for weldable materials. This construction ensure lifelong alignment, surface will be machined and ground finished. Drum Rotating on antifriction self aligning ball roller bearing with standard Housing. Heavy duty drive arrangement for smooth, continuous and trouble free running. V-Pulley or Variable speed arrangement also provided for optimum performance. The Flaker Machine will be complete with 1440 RPM, 3 Phase, 415 volts, TEFC ISD motor, with gear box, Tray, Hopper, M.S. hood, Belt Guard. Machine mounted on heavy base-plate for trouble free service. It’s optional features is Screw Conveyor, Flaker Breaker, Film thickens controllers, Complete enclosure for Hazardous application. Company also providing pilot unit which is available for, to take running trial on receipt of sample about 15 Kgs. Company carries out the test on it, to produce reliable information’s on outputs and for the scaling of purpose. Flaker used in Acetanilide, Fatty acids, Monochloro acetic acid, Nickel catalyst, Naphthalene, Resin, Waxes and so many other products.

Drum Flakers

Get Price Quote

we offer drum flakers. we are well known manufacturing and supplying company of drum flakers. special features: low power demand - continuous operation - compact installation - closed construction available

Alkyd Resin Plant

Get Price Quote

We manufacture Alkyd resin Plant which is used for making Alkyd resin From long oil & Short oil viz. Soya bean oil, castor oil, Linseed oil .Alkyd resin is widely used in many industry viz. Paint ,Lubricating grease, Coating, Emulsifying agent, Cosmetic( Nail Paints), Detergent, Rubber, Pigment, etc.

Grease Plant

Get Price Quote

We are one of the leading lubricating grease manufacturers in Asia having a strengthened production base at strategic locations in India

Grease Plant

Get Price Quote

We are one of the leading producers and suppliers of Grease Plants. We have years of experience in manufacturing these grease plants. With the time, we have developed great scientific expertise in manufacturing these plants. We manufacture various type of grease plants which have calcium base, soda base, aluminium base, lithium base etc. We have manufactured & erected complete grease plants , we are specialized for saponification vessels, cooling kettle, start co type contractors, pressure vessels, single motor driven dual motion vessels, shearing vessels, versators, pilot plants, attrition mills, planetary vessels etc. These equipments can manufacture various grades of greases such as lithium base, calcium base, Al complex etc.

Grease Plant

Get Price Quote

PETROF is a manufacturer and supplier of Grease Plants and related machinery. Our services affiliated with grease include: Supplying technological equipment & formulations related to grease blending. Providing technical specifications and know how with respect to grease formation.

Drum Flaker

Get Price Quote

Drum flakers (also known as cooling drums) are used for solidifying molten material. After processing on flakers, the material forms films or easily handled flakes and is further processed or packed into containers for transport. A great advantage of flakers is that they offer a continuous process. Salient Features : Variable speed drive arrangement for adjustment of the drum speed for optimum performance, Suitable for a wide range of chemical and pharmaceutical products, Contact parts can be stainless steel, carbon steel, and hard chrome plated depending on material requirements, Accessories include hood, flake breaker, flake conveyor, applicator roller etc.

Grease Plant

Get Price Quote

The projectplant offered by us is the outcome of many years of technical and scientific experience. Modern manufacturing equipment, scientifically developed formulations, the processes, careful supervision at every stage, vast manufacturing, fabrication and design experience are put together to create the project. Accurate process controls, high manufacturing standards, quality controls, repeatable and reproducible conversion efficiency incorporated in the plant ensure very high manufacturing standards resulting in production of complete range of greases of proven qualities.

Drum Dryer Flaker

Get Price Quote

In this conductive dryer, wet feed film (in liquid or paste form) is poured on the rotating metal cylinder. Heating medium flows inside the cylinder. Feed dries into a film and is scraped off. This dryer is suitable for continuous drying. We are best Drum Dryer Flaker Manufacturers. Special Features of Drum Dryer Flaker : Feed can be liquid or pasty Product in powdery, flaky form Uniform drying High thermal efficiency Continuous operation Drying in single step, eliminating need for intermediateconcentration processes Application : Winnies Foods, paraffin wax, clay, fire clay, plaster slag, pasty green waste ,sewage sludge, agricultural products , grain, root vegetables, etc.

Automatic Resin Manufacturing Plant

Get Price Quote

resin plants

Get Price Quote

resin plants, eurotech concrete plants, eurotech concrete mixers

Resin Plant

Get Price Quote

paint machinery, Pharmaceutical Machinery, soap machinery, grease machinery

paint manufacturing machinery

Get Price Quote

paint manufacturing machinery, water bucket, Rice Washer, Champagne Bucket

Industrial Formaldehyde Resin Plant

Get Price Quote

Industrial Formaldehyde Resin Plant, Pva Emulsion Plant, alkyd

Resin Manufacturing Plant

Get Price Quote

Double Expansion Type Tube Sheets, Pva Emulsion Plant, adhesive plant