REVERSE ENGINEERING-3D SCANNING

Get Price Quote

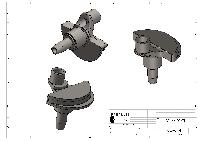

Our 3d scanning facilities technologies will capture 3d measurements from objects as small as a pin head or as large as a production factory. When we remove the constraints imposed by conventional measurement technologies, the scope of applications becomes virtually limitless with 3d, digital data in hand. While much of our work is in reverse engineering and product inspection, there are so many other uses for our 3d laser scanning and 3d measurement data. Our team of highly skilled professionals can transform the raw point cloud or cmm data into output formats that are the foundation for design, documentation, visualization, and analysis as well. 3d laser scanning is a non-contact, non-destructive technology that digitally captures the shape of physical objects using a line of laser light. 3d laser scanners create “point clouds” of data from the surface of an object. In other words, 3d laser scanning is a way to capture a physical object’s exact size and shape into the computer world as a digital 3-dimensional representation. 3d laser scanners measure fine details and capture free-form shapes to quickly generate highly accurate point clouds. 3d laser scanning is ideally suited to the measurement and inspection of contoured surfaces and complex geometries which require massive amounts of data for their accurate description and where doing this is impractical with the use of traditional measurement methods or a touch probe.

Reverse Engineering Services

Get Price Quote

Mechanical CAD Drafting, prototype development service, 3d designing services

Looking for Reverse Engineering Services Providers

Reverse Engineering Services

Get Price Quote

insert mold parts, Polycarbonate Mold, compression moulds, Cad Cam Services

Reverse Engineering

Get Price Quote

electroplating services, 3D CAD Conversion, Finite Element Modeling