3 Roller Hydraulic Plate Rolling Machine

675,000 - 680,000 Per piece

Hydraulic Roll Marking Machine

Get Price Quote

Clients can avail quality tested Hydraulic Roll Marking Machine from our company. Hydraulic Roll Marking Machine, available with us, is precision engineered and in compliance with the highest quality standards. The Hydraulic Roll Marking Machine is very easy to install and operate. A wide range of components can be marked with Hydraulic Roll Marking Machine. Features Easy to operate Automatic compensation for variation in workpiece diameters. Rigidly fabricated, reinforced steel frame. Stress relieved Can mark round workpiece upto 200 mm diameter Can mark flat workpiece upto 170 mm thickness Open back permits marking of long bars. Serial numbers can be marked with automatic indexing Can make upto 4 lines of 6 mm characters, or 8 lines of 3mm characters. Ample daylight permits extensive use of fixturing and tooling for alomost all shapes and sizes of components. Electrically controlled hydraulic operations : Hydraulic cyclinders operate table and marking die slide Table pressure controls depth of mark : ensuring uniform depth. One master foot-pedal control for operating table and die slide cylinders in proper sequence Specially designed cyclinder fitted with hardened bearing. Die slide moves on hardened plate with rollers for precision and long life Components that Can Be Marked : Shock Absorbers, Flanges, Elbows, Bends, Mortar Barrels, Gears, Fuses, Pistons, Couplings, Railroad Bearings, Shells, Axles, Propeller Shafts, Rock Drills, Magneto, Lock Body. Also Availabel Against Specific Orders special Purpose Machines Wherein Daylight can be increased to 425 mm. Stroke can be increased 250 mm. Marking capacity can be increased to 8 lines of 6 mm characters. Specifications Marking Capacity 4 Lines of 6 mm Characters ( in Mild Steel ) 6 Lines of 6 mm Characters 8 Lines of 3 mm Characters Die Slide Stroke : 10 mm Daylight : 285 mm Throat : 90 mm Open Back : Permits Marking of Long Bars Open Distance : 180 mm Between Up-Rights Output : Upto 600 Nos. per hour depending on Length of stroke and shape of component Table Size : 250 X 200 mm. Table Rise : 10 mm Hydraulically, 110 mm by handwheel. Table Pressure : 1T to 4T Floor Area : 2000 X 2000 mm Height : 1500 mm Nett Weight : 850 kg Motor : 3HP, 1500rpm, 440 V, 3-Phase, 50 Cycles Pump : 10 Litres / Min Hydraulic Tank : 75 Litres.

Best Deals from Rolling Machine

Shutters Making Machine

Get Price Quote

we are the manufacturer of shutter making machine, These machines are designed with the proper bending

Single Shaft Auto Roll Cutting Machine

1,230,000 Per Set

Features : Main driving part: Taiwan AC motor with inverter is employed. Central control unit: programmable central control is used and 20 sizes can be set on the same shaft for auto transfer and cutting. Operating panel: all functions are operated on the 10.4" Taiwan EVIEW LCD touch panel. Motor control system: the central control system is PLC programmable controller. Cutting positioning system: cutting positioning is controlled by Mitsubishi servo motor. The imported high precision ball screw is applied to set the size and the linear slide rail is to bear the load of the cutter seat. Blade feeding positioning system: blade feeding is controlled by Mitsubishi servo motor, and the cutting speed is adjustable in three stages. Auto angle adjustment of circular blade: Mitsubishi servo motor is used to calculate the circular blade angle and the angle change is subject to different materials (the angle change range is ±8°). Quick shaft change system: three kinds of shafts are available and quick change of shafts is applied for different materials.

Roller Embossing Machine

10,000 Per Piece

We are reckoned among the established Manufacturers and Supplier of Roller Embossing Machine. The Embossing Machines we make available are manufactured using quality-tested components and the latest technology. We maintain a large stock of the machines in our warehouse in order to meet the bulk and urgent requirements of the buyers. The entire range of the Roller Embossing Machine is reasonably priced by us.

PURLIN FORMIG MACHINE

Get Price Quote

1 Container (MOQ)

PURLIN FORMING MACHINE C AND Z SECTION WITH SPECIFIC LENGTH,WIDTH AND THICKNESS

Paper Roll To Sheet Cutting Machine

Get Price Quote

Thermal Paper Roll Printing Machine

Get Price Quote

Eye Rolling Machine

Get Price Quote

Features: - All fabricated design - Supplied with quick lifting centre pin arrangement with hand operated lever - Capacity maximum of leaf eye rolling 100 x 12 mm Installation: - The machine should be installed on a concrete foundation close to the heating furnace. Hot end chambers / pre-bending of leaf spring should be done. - After Hot end chamfering of lead on press, hot flat end should be reheated. Two Eye Rolling diameter pins should kept ready. One pin is used for eye rolling while the other pin cools in the water tank kept below the eye rolling machine. Corresponding to the pin size, the required bush is to be mounted on the Eye Rolling Machine. Please make all size pins and corresponding bushes as per your requirement. Brief Operation: Put eye rolling pin in its position. Place the pre-bent portion of the hot leaf into the machine, tighten the clamping screw and manually push the pivot end of the machine using a long pipe. After completing 3/4th bend / eye, release the clamping screw and pull the pivot end of the machine to the starting point. Again clamp the screw and push the pivot end again to complete the eye. Release the screw and pull the pin upwards. Remove the eye using a hammer and die correct the eye size and Inside Diameter. Put this eye rolling pin in the water tank for cooling and use the other pin for the next rolling operation.

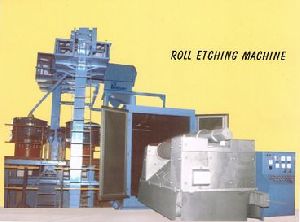

Roll Etching Machine

Get Price Quote

Hot Roll Rotary Coder Machine

Get Price Quote

Fully Automatic PLC based On-line Hot Roll Rotary Coder Model HRC-35-O with blue Digital LCD display, soft touch keys & production counter. This coder (equivalent to MARKEM coders) uses instant dry hot wax ink roller and heated brass stereos for smudge free printing of 4 to 6 lines of size 35 X 50 mm & speed upto 300 packets per min. Instantaneous speed feedback is obtained by Digital Encoder for synchronization. (Free accessories include 2 mm Brass type Numeric Character Set, Hot Wax Ink Cartridge & Print Sensor). This type of coder is suited for continuous & intermittent FFS (Form Fill Seal) machines, pouch packing / flow wrapping / blister pack machines, biscuit / masala / oil / milk / water packing, conveyor systems, winder-rewinder system, etc.

Flute Roll Corrugation Machine

200,000 Per Set

1 Set(s) (MOQ)

To furnish the varying desires of our customers, we are immersed in offering a world class consignment of Flute Roll Corrugation Machine. Features: Customized Reliable Fine finish Tough construction Durable

Slipout Type Hand Bending Roller Machine

Get Price Quote

This is two roll driven three roll slip-out type plate bending rollers. Slip-out type beding rollers have all three rolls of same diameter and is ideal machine to take out rapidly formed small diameter cylinders without deformation. The machine is available in various sizes from 300 x 1.0mm capacity upto 1250 x 1.0mm in mild steel capacites. Motorized slip-out type bending machine is also available. Kindly ask for details.

Plate Rolling Machine

Get Price Quote

To keep a strict check on the quality of the products, we have hired professional quality analysts having rich domain experience. A famed name, the company is enlisted amidst the well-known Suppliers of Plate Rolling Machine.

cloth rolling machine

Get Price Quote

The B-Tex Mini Table Rolling Machine, BIM-TRR is reliable tool for mending and inspection jobs.Top and Bottom tube light allows perfect defect view and adjustable inspection angle allows easy mending work. Sliding chain can be provided for operator. BIM-TRR is solution between Rolling and Mini Inspection process.

batch roller machine

Get Price Quote

Batch Former form conical shape of kneaded mixed and cooled batch of Lollypop Candy Toffee for further feeding into Rope Sizer. It is fitted with heaters to keep the batch warm. It's lifting and lowering mechanism helps the batch coming forward automatically. It is fitted with Stainless Steel Rollers. Electrical reverse and forward system is required extra for operating the batch former. There is ease of taking out rollers for cleaning operation.

cloth rolling machine

38,500 - 84,500 Per piece

Slipout type Hand Sheet Bending Roller machine

Get Price Quote

This is two roll driven three roll slip-out type plate bending rollers. Slip-out type beding rollers have all three rolls of same diameter and is ideal machine to take out rapidly formed small diameter cylinders without deformation. The machine is available in various sizes from 300 x 1.0mm capacity upto 1250 x 1.0mm in mild steel capacites. Motorized slip-out type bending machine is also available. Kindly ask for details.

Wire Rolling Machine

100,000 Per Piece

1 Piece(s) (MOQ)

We are offering our wire and sheet rolling machine 3.5" x 2" are extensively used in workshops that manufacture & design jewelry. These rolling machine consist of steel rollers between which the metal is passed for compression or shape changes. The wire machines have the capability to roll wires for a tapered or shaped effect. Features: hassle-free performance low maintenance high efficiency rugged construction

Small Rolling Machine

Get Price Quote

Obliged to our hard-earned market thoughtful and profound knowledge, we have been able to bring forth a supreme quality assortment of Small Rolling Machine. Being available to the customers in diverse sizes and specifications in tandem with their detailed requirements, the provided products are developed using best-grade raw material and cutting edge technology.Features: Robust Excellent surface finish Low maintenance

Drop Roller Candy Machine

Get Price Quote

Drop Roller Candy Machines are a low cost solution to producing die-formed hard candy sweets. The machine can be used to produce either solid single colour candies or two-colour layered candies. A set of brass rollers with the candy design engraved into them continuously forms a ribbon of candy into the required shape. The formed candy is then left to cool before the sweets can be broken up, sieved and then processed further or packaged.The brass rollers can be engraved in various shapes including ovals, rounds, balls, oblongs, pears, lemons, flat drops or various other novelty shapes. Some bar products can also be made on specially designed rollers.Further machines can be added to make this a more automated process if required. Examples designs Drop roller die designs Roller designs

Fabric Rolling Machine

45,000 - 130,000 Per piece

1 piece (MOQ)

FULLY M.S BODY STRUCTURE • Compact winding directly on paper tubes• Highly productive due to short set up and less change over timeOptional• Varible Speed• Mechanical Counter Meter

Thread Rolling Machine

80,000 Per Piece

1 Piece(s) (MOQ)

Mechanical Plate Rolling Machine

Get Price Quote

These Heavy Duty Plate Bending Machines Employ The Orthodox Three Roller Pyramid Principle. Bottom Rolls Are Fixed And Are Driven By A System Of Gears And Worm Reduction Gear Box Whereas The Top Roll Has A Vertical Up And Down Movement Through. The Housings Are Steel Fabricated With Large Bearing Surface Area. The Rolls Are Of Wear Resistant Forged Steel And Are. Amply Dimensioned To Keep The Top Roll Horizontal When The Formrd Shell Is To Be Extracted By Retracting The Trunion. Horizontal Grooves Are Provided Throughout The Length, Of Rolls For Additional Gripping And Correct Feeding. Indicators Are Provided At Both Ends Correct Feeding. Indicators Are Provided At Both Ends For Correct Top Roll Pressure.

Slotted Cable Tray Roll Forming Machine

Get Price Quote

Our organization is counted among the leading manufacturers, wholesalers, traders, exporters, and suppliers of supreme quality Slotted Cable Tray Roll Forming Machine. Made from high quality metals in compliance with the industry set parameters, these machines are widely appreciated by our clients. Offered machines are known for their shock proof body construction and high resistance to corrosion.

Forming Automatic Roll Fed Machines

Get Price Quote

Thermoforming on automatic roll-fed machines for formingpunching operation in the RDM, RDM-K field of high-performance 3rd Generation Thermoformer. RDM-K machines equipped with formingpunching technology stand for precise mechanical drives, high product quality, performance and reliability. The user can select from a comprehensive, product-oriented series with various forming areas and equipment levels.

Fine Rolling Mill Machine

Get Price Quote

The m series is specifically developed for volume production environments, employs a versatile and highly configurable approach to enable machine solutions to be engineered to satisfy the unique requirements of specific application. Developed using the vary last machinery control technology to provide solutions for both strip and wire lamination processes, and for either breaking down or finishing application. the M series provides a full and complete range of machinery solutions, each being individually configured to provide the most effective solution for the specific applications. Range of working table formats from 130mm to 220mm for strip, and form 240mm up to 350mm for wire applications. Optional coiling units. Alternative material tensioning, and machine cut of it the event of material breakage. Separated oil lubrication circuit for working material available optionally Fully automated open circuit oil lubrication circuits are incorporated to maintain and guarantee the rolling heads and all critical components, providing for the highest levels of finished product quality and an extended life cycle of the machinery. General characteristics Working table formats: 130 to 350 mm Velocity : 6.0m/min Rolling tolerances: 25 to 10um – nominal 2um – machine Absolute.

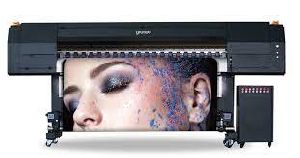

UV LED Roll to Roll Printing Machine

1,450,000 - 2,250,000 Per Set

Hydraulic Thread Rolling Machine

Get Price Quote

The 3 rollers HH-3R rolling machine operates hydraulically. The simultaneously and concentricity of three forces at 120° assures stability of the work piece during the rolling and as consequences the maximum geometrical precision of the work piece. The elimination of the support blade consents a better finishing of the piece and execution of particularly delicate profiles. The machine is suitable for rolling pipes, lapping work, threading with high class precision and for mass production of Scaffolding pipe jack and solid jacks screws etc.

Reverse Roll Coating Machine

Get Price Quote

Reverse roll coating is a roll-to-roll coating strategy for wet coatings. It is separated from other roll coating systems by having two reverse-running nips. The metering roll and the applicator roll turn in inverse directions with the rate contrast of 50% to 150%, with an exact crevice between them. The surface of the applicator roll is stacked with an overabundance of coating before the metering nip, so its surface rises up out of the metering nip with an exact thickness of coating equivalent to the crevice. In reverse roll coating, the coating material is measured onto the applicator roller by exactness setting of the hole between the upper metering roller and the application roller underneath it. The coating is "wiped" off the application roller by the substrate as it goes around the bolster roller at the base. The chart delineates a 3-roll reverse roll coating process, despite the fact that 4-roll forms are normal.