Ultrasonic Thickness Gauges

Ultrasonic Thickness measurement is non destructive method of measurement and particularly, suitable for components having access only from one side, where conventional gauge cannot be used.

...more

ULTRASONIC TEXTILE CUTTING

Ultrasonic energy has found extensive use in cutting of textiles, woven sacksplastic etc and their downstream processing. Many of these uses are based on the ability to use ultrasonic energy to induce heat and pressure by vibratory action.

...more

Ultrasonic Telso-Splice

Roop telsonic offers high powerhigh precision equipment for wire splicing. Precision and reliabilty are decisive preconditions for electrical connections in automobile wire harnesses. Ultrasonic welding ensures flawless electrical conductivity in the wire splices over years and years.

...more

Ultrasonic Multi Chamber Cleaning Systems

Advanced proven swiss technology. Micro-processor controlled ultrasonic generators. Options available for multiple frequencies: 20 25 30 36 40 80 120 khz.

...more

Ultrasonic Metal Welding

ROOPTELSONIC offers high powerhigh precision equipment for wire splicing and linear welding process. Our Rotary Ultrasonic Welding Head is available for continuous assembly operations which has been a revolution in the solar thermal Industry.

...more

ultrasonic cleaning systems

Till today, many industries use chlorinated solvents for cleaning various components. Although solvent based cleaning system like ultrasonic vapor degreasing systems does give good cleaning results but adopting new technology has become imperative to avoid use of highly chlorinated solvents due to strict environmental regulations worldwide.

...more

ultrasonic cleaning components

The success of a large cleaning system depends mainly on Ultrasonic Generators and Transducers. We offer efficient ECO-Generators. Due to their compact design they require less space and are usable in a raw environment. This is allowed by an indirect cooling which ensures that the cooling air does not get in contact with the electronic components.

...more

Ultrasonic Bath

Ultrasonic bath works on the principle of Ultrasonic cavitation i.e. high frequency vibrations, generate agitation in liquid resulting into rapid formation and collapse of minute bubbles in liquid. Implosion of bubbles with high pressure on exposed surface of component dislodges and removes contamination like dirt, dust, oil, grease, chips, wax, lapping paste, carbon etc.

...more

Spin Welding Machine

Spin Welding as the name implies, is a friction welding technique to join thermoplastic parts. It is essential the parts to be joined or atleast their joint areas must be circular for this method of joining to be used. A shallow Machining groove (tongue & groove) is desirable to index the two parts and to provide a uniform bearing surface.

...more

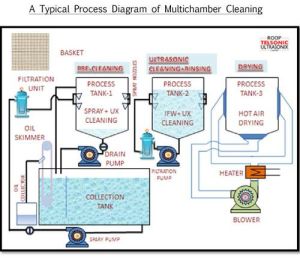

Multichamber Cleaning Systems

Pre-cleaning. Ultrasonic-cleaning. Rinsing. Anti-rust coating. Hot air drying. Vacuum drying. Selection of number of stages depends upon the desired cleanliness level. Available systems: - 3 to 10 chambers.

...more

metal welding

To join wired connections and to create connections in small, delicate circuits. Junctions of wire harnesses are often joined using ultrasonic welding.

...more

Linear Ultrasonic Plastic Welding Systems

As a joining process for industrial thermoplastics, the ultrasonic method is very well proven in practice. Particularly in the production of mass- produced parts, the process offers definite advantage over previous methods such as for instance high strength, clean weld seams, fast processing time, extremely low rejection rates and low energy consumption. In addition,this technique can be used successfully for riveting, forming, stacking as well as embedding of metal parts into thermoplastic materials.

...more

Industrial Tanks

The demand for industrial cleaning has been ever increasing as highly cleaned components are in-dispensable for various production units. This is not only to create conditions for trouble free manufacturing but also decides the quality and service life of the product. Which cleaning should be applied for demand will depend on various aspects: type of component, material, surface quality, type of contamination and required cleanliness.

...more

High Precision Industrial Ultrasonic Cleaning Systems

Cleaning is, almost by definition, a part of any manufacturing process for the removal of sufficient surface contamination to make something suitable for the next phase of its use. It may come in at the raw material prep stage, some intermediate manufacturing stage, and prior to surface finishing such as plating or painting or before final packaging. Industrial cleaning system plays a key role during final manufacturing stages for the cleaning of various components .it's demand has been ever increasing as highly cleaned components are needed for various production units in reducedless time. This is not only to create conditions for trouble free manufacturing but also decides the quality and service life of the end product. The cleaning sequence depend on various aspects like: type of component, material, surface quality, type of contamination and required cleanliness level in terms of millipore as well as particle size.

...more

Customized Welding Projects

Building of special purpose customized machines is rtul's speciality (especially for the automobile sector). For many years, we have designed and built systems, which cater to the precise demands of the customer.

...more

Continuous Metal Welding

Ultrasonic has been well accepted as a cold welding technique for continuous welding of solar thermal components which unchanged the basic property of the copper tube and the copper sheet.without using any external solder or adhesive, the metallurgical bond between the two coppers aluminum is achieved by ultrasonic technique. This ensures a very high degree of thermal efficiency. The resultant weld is continuous and there are no dry spots. The ultrasonic bond is achieved at a molecular level and as there is no external material, even the small width of the weld provides good transfer of the heat.

...more

Ultrasonic Hand Welder

The Ultrasonic hand welder "Handystar" is ideal for small welding, riveting and inserting operations using thermoplastic materials; where manual assembly is required. The very compact instrument is suitable for small series application and laboratory.

...more

ULTRASONIC TEXTILE SEALING

Ultrasonic energy has found extensive use in cutting of textiles, woven sacksplastic etc and their downstream processing. Many of these uses are based on the ability to use ultrasonic energy to induce heat and pressure by vibratory action.

...more

Ultrasonic Machining

Ultrasonic machining is a process wherein a vibrating tool oscillates at ultrasonic frequencies and removes material from the workpiece, aided by an abrasive slurry which flows freely between the workpiece and the tool.

...more

Ultrasonic Concrete Tester

All four models are fully portable instruments for assessing the quality of concrete either as in situ or precast. These are designed with field conditions in mind and are very simple to operate. Accuracy and stability is unmatched. Equipment generates low frequency pulses and measures the time of flight in the material. The time is displayed on screen. The time of flight and the velocity of sound in the material are correlated to estimate the mechanical strength of concrete.

...moreBe first to Rate

Rate This