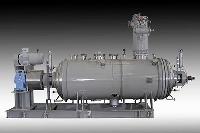

Rotary Vacuum Dryer

Get Price Quote

The drying in a Rotary vacuum dryer is a batch operation under vacuum. It is possible to dry heat sensitive materials at well below boiling points of water and solvents. Drying time depends on material being dried, amount of solvent or water to be removed, desired final moisture content, permissible jacket temperature etc. The dryer is available in sizes ranging from 100 liters to 20,000 liters gross volume. The volume of wet material loaded into the dryer is usually restricted to 40-45% of gross volume.Rotary vacuum dryer has some typical applications in pharmaceuticals, organic chemicals, pasty materials, insecticides, pesticides, solvent recovery, dye intermediates, dyestuffs and in others industries.Material of Construction (MOC) Offered : - CS (IS 2062 Gr A/B, SA 516 Gr 60/70, BQ), SS 316, SS 304, SS 316 L, SS 304 L. SS 310, MONEL, INCONEL, TITANIUM, HASTALLOY, PP/FRP ETC.Features : Equipped with different designs of agitators depending on the material to be dried. Unique quick opening discharge valve permits direct packing of dry product into bags or drums. Breaker rods are provided to prevent lump formation and allow quick and complete drying. Shaft sealing by mechanical seals is also available. N2 pulse jet dust filter (self cleaning type).

Rotary Cascade Dryer

800,000 Per piece

1 piece (MOQ)

The complete drying plant compromises Rotary Cascade Dryer, Air Heater, Dryer Inlet Hood, Exhaust Hood, Exhaust Air Fan & Ducting and all necessary Controls. Duty : To Dry about 750 Kg/hr. of Chilly Flakes from approximately 20% initial moisture to 8-10 % final moisture. Dryer Drum : 3 Ft Diameter X 28 Ft. long dryer drum fabricated in Stainless Steel plate SS-304 , with internal flights and lifters fabricated and bolted to Stainless steel angle sections welded to the shell plates to ensure adequate contact between the drying air and the material being processed. The drum is fitted with two cast or forged steel tyres, mounted on carbon steel spacer blocks fitted to a reinforcing band. The tyres run on four cast or forged steel support rollers shrunk fit on steel shafts with shaft mounted spherical roller bearing plummer blocks. A segmental cast steel chain ring is fitted around the periphery of the dryer drum. Support Frames: The complete dryer drum assembly is supported on two fabricated carbon steel roller support frames, the feed end support frame carrying the locating roller assemblies. Both roller support frames are fitter with safety guards. Drum Drive: The dryer drum is driven by a T.E.F.C. electric motor through V-belt drive, gearbox, pinion and chain to the drum drive chain wheel. Motor, gearbox and V-belt, etc. are mounted on a fabricated carbon steel baseplate. All drives are completely enclosed in suitable safety guards. Air Heater : The drying air is provided by means of Electrical Operated, firing into a refractory lined carbon steel combustion chamber connected to the dryer inlet end hood. It can also be operated with Electrical Heater of 30 KiloWatts rating. Inlet End Hood :The inlet end of the drum is totally enclosed with a Stainless steel fabricated enclosure, complete with labyrinth seal. and stainless steel material inlet chute. The inlet hood is supported by a suitable rolled steel section support structure. Outer End Hood : The outer end of the drum is totally enclosed with a carbon steel fabricated hood complete with inspection access door, exhaust air outlet chute. A labyrinth type flexible seal is fitted to the rear hood plates around the drum opening. The outlet end is supported by a suitable rolled steel section support structure. Exhaust Air Fan : The exhaust air is drawn from the dryer by a centrifugal fan, complete with electric motor, V-belt drive and drive guard. Exhaust Air Ducting : The exhaust air from the dryer is conveyed via a Stainless steel duct from the outlet end hood to the cyclone and from the cyclone to the exhaust fan. A manually operated butterfly type valve damper is fitted in the exhaust duct between the cyclone and exhaust fan. Control System : Inlet air temperature is measured by means of a thermocouple located in the inlet end hood connected to a temperature indicator/recorder. Exhaust air temperature is measured by a thermocouple located in the exhaust air duct connected to a temperature indicator/recorder. The Electrical output is controlled by means of a suitable Thermostat via a suitable transmitter from either of the two temperature indicator controllers. All necessary motor control gear, relays, overloads, etc. and temperature indicators/recorders are housed in a carbon steel control cabinet which will be prewired for correct sequential star-up and operation of the plant.

Best Deals from Rotary Dryers

Rotary Cascade Dryer

Get Price Quote

1 Piece (MOQ)

The complete drying plant compromises Rotary Cascade Dryer, Air Heater, Dryer Inlet Hood, Exhaust Hood, Exhaust Air Fan & Ducting and all necessary Controls. Duty : To Dry about 750 Kg/hr. of Chilly Flakes from approximately 20% initial moisture to 8-10 % final moisture. Dryer Drum : 3 Ft Diameter X 28 Ft. long dryer drum fabricated in Stainless Steel plate SS-304 , with internal flights and lifters fabricated and bolted to Stainless steel angle sections welded to the shell plates to ensure adequate contact between the drying air and the material being processed. The drum is fitted with two cast or forged steel tyres, mounted on carbon steel spacer blocks fitted to a reinforcing band. The tyres run on four cast or forged steel support rollers shrunk fit on steel shafts with shaft mounted spherical roller bearing plummer blocks. A segmental cast steel chain ring is fitted around the periphery of the dryer drum. Support Frames: The complete dryer drum assembly is supported on two fabricated carbon steel roller support frames, the feed end support frame carrying the locating roller assemblies. Both roller support frames are fitter with safety guards. Drum Drive: The dryer drum is driven by a T.E.F.C. electric motor through V-belt drive, gearbox, pinion and chain to the drum drive chain wheel. Motor, gearbox and V-belt, etc. are mounted on a fabricated carbon steel baseplate. All drives are completely enclosed in suitable safety guards. Air Heater : The drying air is provided by means of Electrical Operated, firing into a refractory lined carbon steel combustion chamber connected to the dryer inlet end hood. It can also be operated with Electrical Heater of 30 KiloWatts rating. Inlet End Hood :The inlet end of the drum is totally enclosed with a Stainless steel fabricated enclosure, complete with labyrinth seal. and stainless steel material inlet chute. The inlet hood is supported by a suitable rolled steel section support structure. Outer End Hood : The outer end of the drum is totally enclosed with a carbon steel fabricated hood complete with inspection access door, exhaust air outlet chute. A labyrinth type flexible seal is fitted to the rear hood plates around the drum opening. The outlet end is supported by a suitable rolled steel section support structure. Exhaust Air Fan : The exhaust air is drawn from the dryer by a centrifugal fan, complete with electric motor, V-belt drive and drive guard. Exhaust Air Ducting : The exhaust air from the dryer is conveyed via a Stainless steel duct from the outlet end hood to the cyclone and from the cyclone to the exhaust fan. A manually operated butterfly type valve damper is fitted in the exhaust duct between the cyclone and exhaust fan. Control System : Inlet air temperature is measured by means of a thermocouple located in the inlet end hood connected to a temperature indicator/recorder. Exhaust air temperature is measured by a thermocouple located in the exhaust air duct connected to a temperature indicator/recorder. The Electrical output is controlled by means of a suitable Thermostat via a suitable transmitter from either of the two temperature indicator controllers. All necessary motor control gear, relays, overloads, etc. and temperature indicators/recorders are housed in a carbon steel control cabinet which will be prewired for correct sequential star-up and operation of the plant.

rotary vacuum dryers

Get Price Quote

As a celebrated Manufacturer and Supplier of Rotary Vacuum Dryers, we attempt to gain 100% customer satisfaction. Our wide range is manufactured using matchless raw material. We meet the highest parameters and norms of quality set by the industry. Designs are made by keeping several specifications in mind. The quality on offer, which is loaded with features such as high functionality and minimal maintenance, is available for economical prices.

Rotary Dryers

120,000 Per Piece

1 Piece(s) (MOQ)

Micro processor based temp. control 22 RPM Heating Medium – Water (99 ° C max) Available in standard two models: 12X250 ml. and 18X250 ml. and custom design also

Rotary Cascade Dryer

Get Price Quote

ROTARY CASCADE AND ROTARY LOUVRE DRYER AND COOLER 1500 KGS.lHR. BONE MEAL COCURRENT ROTARY DRYER SAKAV DRYERS handle all types of materials. Recognising that virtually every drying application is unique. Each Rotary Cascade Dryer is purposely designed to meet specific matenal characteristics by analysing the client's process requirement. the correct design solution is assessed & selected by. Designed for Bulk drying of: Minerals· Metal Ores - Fertilisers· Foodstuff - Chemicals -Industrial & Domestic waste. WIDE RANGE OFF GRANULAR MATERIAL Aggregates' Aluminium Oxide' Ammonium nitrate' Ammonium sulphate' Andalousite Animal manure Barium Carbonate' Basic Slag' Bauxite' Benlonil - Blanose Bone meal Bone Powder' Borates Calcium Chloride' Carbon Black pellets' Cement Raw meals' Chicken waste' Chrome Ore' Citric Acid Clay earth' Clays' Coal' Cobalt oxide' Coke Breeze Copper Concentrates' Copper Lead tin alloy· Copper Slag· Copper Sulphate' Copper wastes Cotton seed' Crushed Glass' Crushed Marble' Crystals' Dextrose monohydrate' Dicalcium Phosphate' Egg shell' Feldspar- Ferrile Ferronickel Fertilisers Flint Chips' Garbage wastes Gypsum' Gypsum' Heamatite Herbicides' Herbicides' Ilmenite' Industrial wastes' Kaolin Lardstone Limestone' Maqnesiurn Sulphate' Maize germs' Montmorillonite clay· Nickel Oily chlorate' Potassium Nitrate' PPT Silica' Quartz' Rawa Refractories' Rock Phosphate Rubber' Salt· Sand' Sludges' Sodium Chloride' Sodium monoglutamate Spath fluor' Sugar Talc' Titanium Dioxide' Titanium oxide Urea' Wine tarter' zince oxide. FEATURES • HIGH AUTOMATION • LOW MAINTENANCE • CONTINUOUS OPERATION • LOW OPERATING COST OPERATING TEMPERATURE :- 60°C to 1OOO°C. CAPACITY :- 5 TPD TO 150 TPD SIZE & MOISTURE :- Capable of Handling different product particle size & moisturecontent. SYSTEM Drying / cooling is achieved by passing the material to be processed through a rotating cylinder through which also passes a current of tempered air. Lifters/flights or louvres in the case of rotary louvre dryer, are fitted to the Internal surface of the cylinder to give intimate contact between product and drying or cooling air stream. In Rotary Louvre dryers the material IS not lifted and dropped through the drying air stream, therefore less product breakdown occurs. Rotary Louvre dryers can also be arranged for multi-stage drying, or drying and cooling in one Unit. DRYER PRINCIPLE Co-current Flow Rotary Cascade Dryers, sticky and heat sensitive materials, since the wet material IS exposed to the highest temperature gases, the initial heat transfer rate is very high, rapidly evaporating surface moisture. The Immediate and dramatic fall in gas temperature prevents a sudden Increase in the matenal and shell temperatures. The final product is in contact with the lower temperature gases enabling the moisture content to be readily controlled thereby avoidrnq over-drying. Counter-Current Flow drying in a Rotary Cascade Dryer gives lower product moisture than co-current flow for a given inlet temperature. However, its use with heatsensitive rnatenals IS limited since the dryed product comes into contact with the heating medium at its highest temperature. It is suitable for application where an extremely low moisture content is required or where a higher product temperature is anadvantage. HEATING MEDIUM Gas. Diesel, oil, electric, stream. The drying gas are provided from either a direct fired furnace or an indirect heat exchanger within the range 100 to 1000 C using solid, gaseous or liquid fuel. Only products of combustion or indirectly heated gases enter the Rotary Cascade Dryer. This prevents surface contamination while reducing the risk of damage or fire when handeling more sensitive materials. A two fan balanced draught system IS used to provide the maximum degree of control & flexibility. In arrangements and the drying gases are provided by a locally mounted burner projecting the flame down the centre of the dryer through which the material cascades. This design gives even greater thermal efficiency due to the higher temperature differential, the direct flame contact and the radiation effect, when processing materials which can withstand high gas temperatures without deterioration. CONSTRUCTION Carbon, Stainless or custom alloy steel plate, with external reinforcing bands for fitting of tyres and drive rings. Flights and lifters or louvres are welded or bolted internally. Confifuration is determined by application. DRIVE Drum is rotated by an electric motor through V-belts, gearbox, pinion and either heavy duty chain to a chainwheel or spur gear drive ring bolted around the dryer drum. For high temperature operation, tangent plates are utilized to allow for differential expansion. CLOSURES & SEALS Ends of drum may be enclosed by carbon or alloy steel fabricated end plates or hood With Inlet/outlet chutes and suitable seals Note : Dimensions and the other data of the Rotary Dryers depend on the material properties, water content. dryness, drying capacity, etc. The values of motor horsepower given in the table are those required to rotate the rotary dryer alone. The figures do not Include the horsepower requirements to operate the exhaust, burner material feeder etc.

Rotary Vacuum Dryer

Get Price Quote

Rotary Vacuum Dryer

Get Price Quote

Rotary Vacuum Paddle Dryer The Rotary Vacuum Paddle Dryer is a high efficiency dryer, specially designed for products with high viscosity during drying phase, with high torque requirements. The principle of the Paddle vacuum dryer is its operation through a body, shaft and blades which is fully heated to maximize heat exchange with its blades rotating very close to the wall at low speed for a continuous renewal of the product in direct exchange with the wall.

Rotary Dryers

Get Price Quote

The Rotary dryers are made up of a large, rotating cylindrical tube, usually supported by concrete columns or steel beam, it represents the oldest continuous and most common high volume dryer used across industries. KERONE is having more than 40 years experience in desinging, manufacturing , erection and commissioning various type of Rotary dryers. The typical arrangement of the rotary dryers are the feed materials passing through a rotating cylinder termed a drum. The cylindrical shell usually constructed from steel plates, slightly inclined, typically 0.3-5 m in diameter, 5-90 m in length and rotating at 1-5 rpm. It is operated in some cases with a negative internal pressure (vacuum) to prevent dust escape. The drum is mounted to large steel rings, termed riding rings, or tires that are supported on fixed roller assemblies. The rotation is accomplished by either a direct drive or chain drive, which demand a cinch gear or cog gear, severally, on the drum. As the dryer rotates, solids are picked up by the flights, lifted for a certain distance around the drum and showered through the air in a cascading curtain. Most of the drying occurs at this time, as the solids are in close contact with the gas. Flight action is also partly responsible for the transport of solids through the drum. Feature of the Rotary Dryer Efficient dryer for drying of materials with high moisture contents. Handles a wide size range of materials with extended residence times. Design permits highest possible drying temperatures. Drying, cooling or calcination. High thermal efficiency.

Rotary Dryer

500,000 - 50,000,000 Per piece

Rotary Dryers are used for drying wet powders, chemical, cakes, etc, which are easily breakable and dispersible. The rotary dryer consists of a rotating drum with angle lifting blades which lift the feed as the drum rotates and showers it in the stream of hot air flowing through the drum.

Rotary Dryer

Get Price Quote

We are a leading rotary dryer manufacturer and exporter, brings to you its wide range, which is classified as direct or indirect (air heating method), current or counter current (material air contact). While the rotary dryer is in use, the material should be dried and uniformly dispersed over the entire cross-section. Widely used in various industrial purposes, our rotary dryer can also be customized based on the properties of the material. salient featuresmaterial is passed through heated airdryer is operated through a girth gear and tyre arrangementleast air leakagelow operating and maintenance costsperfectly suited for high volumeshigh thermal proficiency these dryers are used to handle following materialclaysmaize germscoaloresandindustrial sludges

Trunion Rotary Dryer

Get Price Quote

We offer high quality trunnion rotary dryer for our client's. Trunnion rotary dryer are made by using very high quality raw material which ensures hassle free work performance at its user end. We offer trunnion rotary dryer at most affordable prices. Cwt : 1530 kg. Material : cast steel shaft : shrunk fitted.

Rotary Dryers

Get Price Quote

Directly heated with hot air as well Indirectly Heated Dryers. Temperature Range: 50oC – 400oC.Hot Air :By Liquid Gaseous Fuel Electrical. Purpose :Drying, Roasting, Pre-heating, Low Temperature reactions. Capacity :50 kghr. – 25000 kghr.Sizes:Diameter : 0.4 mtr. – 3 mtr. Length : 3 mtr. – 45 mtr.Application :Mineral Processing Chemical Processing Food Processing Pharmaceutical Industries.

Rotary Vacuum Dryer

Get Price Quote

Rotary Vacuum Dryer has some usual applications in organic chemicals, pharmaceuticals, pasty materials, insecticides, pesticides, solvent recovery and in others industries. We are a noteworthy Rotatory Vacuum Dryer Manufacturer, Exporter and Supplier in Maharashtra (India). We produce a highly functional and precision based range of Rotatory Vacuum Dryer by using high quality construction materials and advanced technology in compliance with the set industrial norms and standards. Customers can avail our product at the most reasonable prices.Working : The drying in a rotary vacuum dryer is a batch operation under vacuum. It is possible to dry heat sensitive materials at well below boiling points of water and solvents. Drying time depends on material being dried, amount of solvent or water to be removed, desired final moisture content, permissible jacket temperature etc. The dryer is available in sizes ranging from 100 liters to 20,000 liters gross volume. The volume of wet material loaded into the dryer is usually restricted to 40-45% of gross volume. Features : N2 pulse jet dust filter (self-cleaning type) Equipped with different designs of agitators depending on the material to be dried. Unique quick opening discharge valve permits direct packing of dry product into bags or drums. Breaker rods are provided to prevent lump formation and allow quick and complete drying Shaft sealing by mechanical seals is also available Material of Construction (MOC) Offered : CS (IS 2062 Gr A/B, SA 516 Gr 60/70, BQ) SS 316, SS 304 SS 316 L SS 304 L. SS 310 Monel Inconel Titanium Hastalloy PP/FRP etc

Rotary Cone Vaccuum Dryer

Get Price Quote

Salient Features Location of Gland sealing arrangement right next to the shell. Positive circulation of Hot Water is ensured with no chances of by-pass or short circuiting. No Rotary Pressure Joints are used (which are the potential source of leakages). Inert gas purging / pulsing is possible with vacuum "ON" (No need to shut-off Vacuum for Nitrogen admission).

Rotary Vacuum Dryer

Get Price Quote

They are, however, suitable for only free flowing materials, which are readily converted from slurry or wet cake to free flowing powder without exhibiting sticking or lump forming properties during the course of drying operations.

rotary vacuum dryers

Get Price Quote

We are offering rotary vacuum dryers. Rotary vacuum dryers offer clean, simple and effective method of drying wet cake, powder and even slurry. Labor and energy costs are minimal compared to tray dryers and product losses during handling are also negligible. Additionally valuable organic solvents can be conveniently condensed and recovered.

Rotary Venuelather Dryer

Get Price Quote

as per requirement Piece (MOQ)

Rotary Venuelathe Dryer: Salient features: Most efficient batch dryer for lower drying temp. Lowest drying time Good for hard, lump forming solild High solvent recovery Suitable for pastes, slurries Can be used for Reaction, crystallisation, Extraction and Concentration

Rotary Louvre Dryer

Get Price Quote

We are offering rotary louvre dryer. We are well known manufacturing and supplying company of rotary louvre dryer. Special features: high thermal efficiency - continuous operation - compact installation

Rotary Dryer

Get Price Quote

Voice Engineers is Rotary Dryer Manufacturers. It is classified as direct or indirect (air heating method), current or counter current (material air contact). Direct Rotary Dryer Manufacturers operates on the principle of lifting and showering the product through a hot gas stream moving either in parallel or counter flow. The indirect is more useful to small dusty materials. In indirect dryer, there is little or no contact between the product and drying gases as they are heated from the outside the chamber through a stationary jacket fitted with either multiple burners or other external heat source. Rotary Dryer Manufacturers not only reduces moisture content in the product but is also able to heat up the material, stimulating a reaction between two or more materials. This type is known as Rotary Kiln or Rotary Calciner. TheRotary Dryer Manufacturers is driven through a girth gear and tyre arrangement. Seales are provided at the ends to ensure minimum air leakage. The advantages of rotary dryers are: Low operating costs Low maintenance costs High thermal efficiency Typical products handled: Sand Clays Maize germs Coal Ores Industrial sludges Rotary Dryers fall into three main categories: Rotary Cascade Dryers, where material is lifted and cascaded through a hot air stream. Rotary Louvre Dryers, where the hot air stream is passed through a 'rolling' bed of material. Rotary Steam Tube Dryers, where material is lifted and cascaded through a rotating steam tube bundle Rotary Dryers have a similar construction, consisting of a rotating shell fitted with tyres running on a set of support rollers, with a chain or spur gear ring drive.