Water Distillation Unit

manufactured distillation equipment provides high efficiency in the separation process which directly leads to the reduction in the column height and also in lowering the pressure drop. They are available in 45 and 60 degrees of cramp angles, up to 8.0m of diameter sizes and 60-1000 m2m3 of surface areas. Because of adopting special surface treatment in our manufacturing, we are proficient in delivering such distillation equipments which are known for their low pressure drop and exceptional wetting features. Our products are efficient in making high contact area with the rising vapor and the downwards coming liquid. We are moving our trade on a global scale through adopting the new advanced technology that helps in making this process more proficient and less labor oriented.

...more

waste oil recycling system

1 Set(s) (MOQ)

We are providing top class Waste Oil Recycling System. These projects are delivered in agreement with the clientsâ�� requisites to achieve client gratification. The Re-refining of Used Oil: Our job is to remove all the aforementioned contaminants and restore the oil to its original condition. The Process includes: Step 1 - Dehydration: The oil is stored to allow water and solids to separate out from the oil, then the oil is heated to 120 oC in a closed vessel to boil off any emulsified water and some of the fuel diluents. Step 2 - Diesel stripping/Gas oil Removal: The dehydrated oil is then fed continuously into a vacuum distillation plant for fractionation in exactly the same fashion as crude petroleum. The fractions obtained are as follows: · Light fuel and diesel. Oil produces enough diesel from the used oil feed stock to run all the burners and boilers, giving total self-sufficiency in fuel. · Lubricating oil. The bulk of the feedstock will distill off in the plant to produce a lubricating oil fraction. · Residue. The non-distillable part of the feedstock. This contains all the carbon, wear metals, degraded additives and most of the lead and oxidation products. This residue is successfully used as bitumen extender. Step 3 - Lube oil distillation and condensation: The lubricating oil fractions are then passed through an extraction tower in the presence of Methyl pyrrolidone NMP). The NMP is an aromatic selective solvent which, in addition to removing some color and odor, is able to extract all unwanted aromatic contaminants present in the paraffinic lubricating oil fraction, subsequent to fractional distillation. This is important as polycyclic aromatics are very carcinogenic. The base oil thus produced is chemically and physically indistinguishable from virgin base oils.

Brand Name : Hitek

Condition : Good

After-Sales Service Provided : Yes

Power : 30-40 kW

Working Pressure : Atomoaphere

Country of Origin : Mumbai

...more

Waste Oil Distillation Plant

Automatic Grade : Automatic, Semi-Automatic

Condition : New

Used Oil Re Refining Plant

1 Set(s) (MOQ)

Used Oil Re Refining Plant is a profitable opportunity since lube oil can be re-refined as many times as you like, therefore becoming a very attractive business opportunity while safeguarding the environment. Among the available today processes, Hitek Re-Refining Process offers a low energy high yield operation, high quality products and absence of noxious wastes or byproducts. A typical re-refining process is consisting of the following steps. Dehydration Gas Oil Removal Vacuum Distillation Solvent Extraction. RHEPL has developed most cost effective process for used oil re-refining for all type of used oil such as motor oil,base oil,used lubricating oil etc. Approx Price : INR 2000000 Per 1 Ton We Have Cover Following Markets :USA : Montana, Florida, New-Jersey, Alaska-Nevada, New-Mexico, South-Dakota, Texas, etc.Middle East : Jordan, Cyprus, Arabia, Egypt, Yemen, Israel, Kuwait, Saudi, Syria, Oman, etc.Europe : Austria, Finland, Sweden, Albania, Monaco, Croatia, Poland, Italy, Malta, Andorra, etc.Others : Maldives, Bangladesh, Pakistan, Myanmar, Bhutan, China, Nepal,etcIndian Areas : Rajasthan, Orissa, Assam, Haryana, Bihar, Delhi, Andhra-Pradesh, Himachal-Pradesh, Gujarat, Karnataka, Punjab, Mumbai, West-Bengal, Madhya-Pradesh, etc.

Type : Used Oil Re Refining Plant

Brand Name : Hitek

Condition : Good

Application : Re-refining for all type of used oil such as motor oil,base oil,used lubricating oil etc.

Country of Origin : Mumbai

...more

Used Lube Oil Re Refining Plant

Type : Lubricating Oil

Automatic Grade : Automatic, Semi-Automatic

Application : industrial

...more

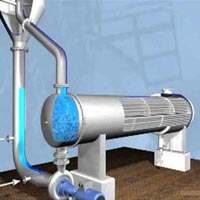

Thermosyphon Evaporator

Thermosyphon Evaporator is considered as the best evaporator in case of diluted feed streams. In our Thermosyphon Evaporator that source of heat is the heating media, which is placed on the shell side. The feed enters into the system through the bottom head than through the help of tubes, it moves to the upward position. Our Thermosyphon Evaporator is highly demanded by laboratories, manufacturing industries, etc. Thermosyphon Evaporator is highly in demand owing to its matchless performance. Features : Economic process Ensure constant operation Best for concentration applications Work well with heat sensitive materials Applications : Herbal extracts Concentration of dilute solution Concentration of fruit juices Solvent recovery from the contaminated solution We Have Cover Following Markets : USA : South-Dakota, Montana, Texas, New-Mexico, Alaska-Nevada, Florida, New-Jersey,etc. Middle East : Egypt, Oman, Syria, Cyprus, Yemen, Israel, Saudi, Arabia, Kuwait, Jordan,etc. Europe : Sweden, Poland, Monaco, Finland, Malta, Italy, Austria, Andorra, Albania, Croatia,etc. Others : Bhutan, Nepal, Bangladesh, Maldives, Myanmar, China, Pakistan,etc Indian Areas : Bihar, Orissa, West-Bengal, Gujarat, Mumbai, Assam, Himachal-Pradesh, Madhya-Pradesh, Punjab, Delhi, Haryana, Andhra-Pradesh, Rajasthan, Karnataka,etc.

Application : Herbal extracts,Concentration of dilute solution,Concentration of fruit juices,Solvent recovery from the contaminated solution,Laboratories, manufacturing industries etc

Brand Name : Hitek

Condition : new

Country of Origin : Mumbai,India

...more

TEG Gas Dehydration Technology

TEG Gas Dehydration Technology We have developed Glycol Dehydration Unit, which is suitably utilized for dehydrating glycol. Most natural gas producers use Triethylene glycol (TEG) to remove water from the natural gas stream in order to meet the pipeline quality standards. This process is required to prevent hydrates formation at low temperatures or corrosion problems due to the presence of carbon dioxide or hydrogen sulfide (regularly found in natural gas). Dehydration, or water vapor removal, is accomplished by reducing the inlet water dew point (temperature at which vapor begins to condense into a liquid) to the outlet dew point temperature which will contain a specified amount of water. Absorption of water vapor in the TEG is the common method. The wet gas is brought into contact with dry glycol in an absorber. Water vapor is absorbed in the glycol and consequently, its dew point reduces. The wet rich glycol then flows from the absorber to a regeneration system in which the entrained gas is separated and fractionated in a column and reboiler. The heating allows boiling off the absorbed water vapor and the water dry lean glycol is cooled (via heat exchange) and pumped back to the absorber. Features � Process guaranty � Efficient energy saving

Feature : Process guaranty,Efficient energy saving.

Application : Triethylene glycol (TEG) remove the water from the natural gas stream in order to meet the pipeline

...more

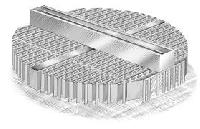

Structured Packings

Structured Packings is used where there is a requirement of azeotropic liquid separation. We have replaced conventional packings in a number of applications with our specially designed Structured Packings, radically altering the morphology of distillation, extraction and absorption systems. Structured Packings offered by us give optimum performance irrespective of the kind industry it is used at. We have a number of models in Structured Packings, each one tried and proven, developed and improved consistently by our technical team. As a reputed Manufacturer and Supplier of Structured Packings, we have satisfied our clients to the fullest. Not just this, we offer Structured Packings at reasonable prices. Range : Sheet based Structured Packings Wire-Web based Structured Packings Advantages : In comparison to Random Packings and Trays of Various types, Re-HI-TEK Packings offer following advantages : Higher Loading/Throughput of Columns, especially for larger diameter Columns. Lower Pressure Drop, especially for vacuum operations - Resulting in lower operating temperatures (important for heat sensitive materials). Low Packing Volume - especially for high number of stage requirement as in Isomers separation. Smaller hold-up Unchanged performance even at lower loadings Specifications PACKING CHARACTERISTICS "HI-PAK" TYPE Specific Surface Area: m2/m3 125 250 350 500 500 700 Voidage(%) 98.5 97.5 96.5 97 95 95.7 F-factor : m/sec (kg/m3)½ 1.0 - 3.0 0.8 - 2.5 1.0 - 2.5 2.0 - 2.5 0.6 - 1.8 1.5 - 2.0 1.8 Number of Stages /m ht. 01/01/05 02/05/03 02/04/12 05/08/12 3.8 - 4.2 07/12/12 Pressure Drop: Torr / m 0.2 - 2 0.4 - 3 2 - 4015 1 - 145 0.4 - 4 1 - 145

...more

static mixer reactor

Static Mixer Reactor is extensively used in all types of reactions whether it is explosive or exothermic. Our Static Mixer Reactor is also utilized in such cases where a constant heat transfer is required. The structure of our Static Mixer Reactor is specifically designed in such a way in order to make radial mixing feasible. It is also suitable for the processes of mixing viscous fluids. Our Static Mixer Reactor is immensely appreciated for features like heat transfer, static mixing, and reaction engineering. We provide Static Mixer Reactor in all sizes and ranges. There Are Some Assumptions Like : Single reaction Plug flow Constant density Controlled environment Main Characteristics : Innovative technique Superior design quality Short residence time Constant distribution We Have Cover Following Markets : USA : Florida, Alaska-Nevada, Texas, Montana, South-Dakota, New-Mexico, New-Jersey,etc. Middle East : Kuwait, Israel, Saudi Egypt, Cyprus, Syria, Jordan, Arabia, Oman, Yemen,etc. Europe : Austria, Poland, Finland, Italy, Andorra, Albania, Sweden, Croatia, Monaco, Malta,etc. Others : Bangladesh, Maldives, Myanmar, Bhutan, China, Pakistan, Nepal,etc. Indian Areas : Assam, Himachal-Pradesh, Punjab, Delhi, Karnataka, West-Bengal, Gujarat, Mumbai, Bihar, Andhra-Pradesh, Orissa, Madhya-Pradesh, Haryana, Rajasthan,etc.

Type : Hitek Standard

Brand Name : HItek

Application : Any Suitable application

Condition : Good

After-Sales Service Provided : Available

...more

Static Mixer Heat Exchanger

Material : Carbon Steel, Stainless Steel, High Alloys and metals, Hastelloy, Tantalum

Solvent Recovery System

Material : metal

Brand Name : Rufouz Hitek

Automatic Grade : Automatic

Application : industrial

...more

Solvent Extraction Plant

Solvent Extraction Plant that we offer is also known as liquid-liquid extraction. Solvent extraction is a method by which different components are extracted from one liquid phase into liquid phase. It can also be said as a process to separate components from the mixture by dissolving it in a solution. Solvent Extraction Plant makes use of such materials that are different chemically and can thermally decompose at higher temperatures. It is suitable for such materials that have same vapor pressures. The product can be easily recovered from the mother liquor without making use of any moving components inside the system. The method is ideal for those materials that can possibly create problems owing to their marginal difference in the specific gravity. Our Solvent Extraction Plant works upon the super class of solvent extraction theory. Also, we provide organic solvent extraction equipment. Featurers Of Solvent Extraction : Most Widespread Technique Speedy Latest Design Good Output Easy Handling Multipurpose Our manufactured products are made up of finest quality of raw materials due to which it ensures durability in the product nature. There are mainly three factors in our designed products which are the main keys of our success and these are quality designs, competitive price and timely delivery. We Have Cover Following Markets : USA : Montana, Florida, New-Jersey, Alaska-Nevada, New-Mexico, South-Dakota, Texas,etc. Middle East : Yemen, Syria, Arabia, Oman, Israel, Kuwait, Jordan, Saudi, Egypt, Cyprus,etc. Europe : Malta, Austria, Italy, Albania, Finland, Croatia, Andorra, Sweden, Poland, Monaco,etc. Others : Bhutan, Nepal, Pakistan, China, Myanmar, Maldives, Bangladesh,etc Indian Areas : Orissa, Bihar, Rajasthan, West-Bengal, Andhra-Pradesh, Punjab, Assam, Gujarat, Himachal-Pradesh, Karnataka, Mumbai, Haryana, Madhya-Pradesh, Delhi, etc.

Brand Name : Hitek

Material : Finest quality raw material

Condition : Good

Features : Most Widespread Technique,Speedy,Latest Design,Good Output,Easy Handling,Mul

Country of Origin : Mumbai

...more

solvent extraction equipment

Solvent extraction process is also known as liquid-liquid extraction. Solvent extraction method is the practice of extracting component from one liquid phase into liquid phase. This term can also be used as a process of separation of a component from the mixture by dissolving it in a solution. They are mainly utilized for materials which are different chemically or can thermally decompose are higher temperatures. They are much suitable for such materials which have usually same vapor pressures. You can easily recover product from the mother liquor without using any kind of moving components inside the system. It is the best technology for those materials which create problems due to marginal difference in the specific gravity. It is also proficient in shifting the batch to continuous type. Within few years we have installed highly developed solvent extraction plant, which runs on the foundation of the super class of solvent extraction theory. Rufouz Hitek Engineers Pvt. Ltd. also supply Organic Solvent Extraction equipments.

...more

Sodium Methoxide Production Technology

Sodium Methoxide Production Technology We have developed a cost effective & energy efficient technology for the production of Sodium Methoxide. Sodium methoxide is used as an initiator of anionic addition polymerization with ethylene oxide, forming a polyether with high molecular weight. Biodiesel is prepared from vegetable oils and animal fats, that is, fatty acid triglycerides, by transesterification with methanol to give fatty acid methyl esters (FAMEs). This transformation is catalyzed by sodium methoxide. Sodium methoxide is a chemical compound with the formula CH3ONa. This colorless solid, which is formed by the deprotonation of methanol, is a widely used reagent in industry. Sodium methoxide is prepared by carefully treating methanol with sodium hydroxide. The reaction is so exothermic that ignition is possible. Initially feed solution will be prepared as 75% Methanol and 25% Caustic in feed tank. This feed from storage tank will fed to the Reaction Column where reaction of caustic takes place with methanol with moisture. After reaction completion, the methanol vapors along with water generated during reaction coming out from the top of the column. The temperature of the First column is maintained through Reboiler (RB- by re-circulation of methanol vapors. 28 - 30% SMO solution coming out from the bottom of the column) will send for stored in the product storage tank. If SMO flakes are required, then bottom product can be send to the dryer/ATFE first from where we will get SMO powder. Methanol separation column is provided separately. We have successfully installed & commissioned SMO plants for 5 tons/day capacity.

Type : Sodium Methoxide Production System

Purity : 100%

Formula : CH30oNa

Form : Deprotonation of Methanol

Brand : Hitek

Country of Origin : Mumbai

...more

Rising Film Evaporator

Rising Film Evaporator that we offer is widely known for providing superior performance in terms of diluted feed streams. Our Rising Film Evaporator features simple construction design and offer cost-effective solution to the user. The processing of the liquids takes place inside the tubes. The evaporator is equipped with a heating media on its shell side. The feed liquid comes into the evaporator through the bottom head and move into an upward position through the tubes. Our Rising Film Evaporator can be used in a variety of applications. Features : Economic process Ensure constant operation Best for concentration applications Work well with heat sensitive materials Applications : Concentration of dilute solution Concentration of herbal extracts Concentration of fruit juices Solvent recovery from the contaminated solution We Have Cover Following Markets : USA : Texas, South-Dakota, Alaska-Nevada, New-Jersey, Florida, New-Mexico, Montana,etc. Middle East : Syria, Cyprus, Saudi, Yemen, Israel, Egypt, Jordan, Oman, Kuwait, Arabia,etc. Europe : Croatia, Andorra, Sweden, Malta, Austria, Albania, Monaco, Italy, Poland, Finland,etc. Others : Bangladesh, Myanmar, Maldives, Bhutan, China, Nepal, Pakistan,etc Indian Areas : Himachal-Pradesh, Gujarat, Bihar, Delhi, Madhya-Pradesh, West-Bengal, Mumbai, Assam, Rajasthan, Punjab, Haryana, Andhra-Pradesh, Orissa, Karnataka,etc.

Feature : Economic process,Ensure constant operation,Best for concentration applications,Work well with heat sensitive materials

Condition : New

Application : Concentration of dilute solution,Concentration of herbal extracts,Concentration of fruit juices.

Brand Name : Hitek

Country of Origin : Mumbai,India

...more

plug flow reactor

Material : metals

NMP Solvent Extraction System

1 Set(s) (MOQ)

We have developed our own technology by continuous research & development. Re-refining of used lube oil is an economically attractive recycling method in terms of resources conservation and environment protection when can be done with help of NMP Solvent Extraction System. Lube extraction is carried out to remove poly aromatic hydrocarbons from the feed stocks to improve Viscosity Index, Color, Oxidation Stability through the action of NMP solvent. Oil and extract stripping, to allow recovery of the last fractions of NMP from both the oils and extract. Solvent Purification by Flash and Dehydration of solvent through distillation. The Feed Oil is fed at the bottom of the extraction column, while the NMP� Solvent mixture is fed to the top of the extraction column. Addition of 20-30% co-solvent along with minimum or no water addition can result in 2-3 wt.% raffinate yields without compromising the raffinate quality.

Type : NMP Extraction System

Condition : Good

Brand Name : Hitek

Grade : A Grade

...more

Multiple Effect Evaporator

Multiple Effect Evaporator Multi-Effect Evaporation is an important procedure adopted to economize the consumption of energy. The Multi Effect Evaporators are designed to economize the consumption of energy. These are designed in such a way that the steam from an outside source is condensed in the heating element of first effect. Further for second effect the boiling temperature of first effect is just too high that evaporated water can serve as the heating medium. The formed vapors than send to condenser, if it is the double effect evaporator. But in the multi effect evaporators, the feed is generally transferred from the one effect to another, which leads to ultimate product concentration which further reaches to one effect of evaporator. Operation can be carried out backward feed or operation forward feed operation.Features : Economized consumption of energy Excellent evaporation from one effect to another Suitable for viscous solutions Excellent heat transfer coefficient Applications : Concentration of sugar solutions to extremely high solids content Removal of water from soaps Finishing concentrator on certain fruit purees Removal of solvents from vegetable oils Sugar beet factories Pharmaceutical industries

Brand Name : Hitek

Application : Concentration of sugar solution to extremley high solids content,sugar beet factories,pharmaceutical

Condition : Good

After-Sales Service Provided : Available

Feature : Economized consumption of energy,Excellent evaporation from one effect to another,Suitable for viscous solutions Excellent heat transfer coefficient.

Country of Origin : Mumbai

...more

microwave equipment

Microwave Dryer is the best suited technology for industries related to pharmaceutical formulations. Thus people are highly preferred this technology over others. Rufouz Hitek Engineers prepare such Microwave Dryer System which can go well with your manufacturing specifications. Recently we have formulated a Dielectric Microwave Dryer in association with SAMEER- which is one the outcome of the Tata Institute of Fundamental Research. The term microwave itself refers to the frequency which lies in the electromagnetic radiation. They are the most commonly used technique that used in our day to day lives. Drying is one of the operation where a big amount of energy is needed for changing the phase. Heat in the microwave is generated through the interaction between the microwave and the part where electromagnetic energy is degenerated.

...more

Lube Oil Re Refining Plant

Type : Lubricating Oil

Automatic Grade : Automatic, Semi-Automatic

Liquid-Liquid Extraction Column

We offer Liquid-Liquid Extraction Column for any type of extractor and highly demanded for those substances which are chemically dissimilar and have chances to undergo thermal decomposition even at the high range of temperatures. Our Liquid-Liquid Extraction Column meets all the requirements of purification. Liquid-Liquid Extraction Column that we offer is easy-to-install and has proper mechanical support as well as low energy rate. It is a mass transfer process in which a direct contact is made by liquid solution with an immiscible or near to immiscible solvent to display the selectivity towards the one or more components of the substance. The process results in two output forms, one is extract that is carrying solvent rich solution and other raffinate, holding the residual feed solution with little bit solute. Network Area : Our manufactured products are made up of finest quality of raw materials due to which it ensures durability in the product nature. There are mainly three factors in our designed products which are the main keys of our success and these are quality designs, competitive price and timely delivery. We Have Cover Following markets : USA : Montana, Florida, New-Mexico South-Dakota, Texas, New-Jersey, Alaska-Nevada, etc. Middle East : Oman, Arabia, Saudi Cyprus, Egypt, Jordan, Kuwait, Yemen, Syria, Israel, etc. Europe : Monaco, Andorra, Albania, Malta, Poland, Croatia, Austria, Sweden, Italy, Finland, etc. Others : Maldives, Bhutan, Nepal, Pakistan, China, Bangladesh, Myanmar, etc. Indian Areas : Haryana, Madhya-Pradesh, Gujarat, Himachal-Pradesh, Mumbai, Assam, Bihar, Andhra-Pradesh, Punjab, Delhi, Karnataka, West-Bengal, Orissa, Rajasthan, etc.

Brand Name : Hitek

Condition : New

Country of Origin : Mumbai,India

Application : Chemical Industries

...more

liquid extraction systems

Brand Name : Rufouz Hitek

Application : industrial

Inline Static Mixer

15,000 Per Piece

1 Piece (MOQ)

Feature : Low-Pressure Drops,Minimum hold-up,

Material : All metals and non-metals

Application : industrial,Mixing of gases, Mixing of pump able fluids

Country of Origin : Made in India

...more

inline mixers

Inline Mixer manufactured by Rufouz Hitek Engineers serve in all major industries related to the engineering fields. They are extensively used to smooth the progress of heat as well as mass transfer. The technique of gashing and reunification helps this device to becoming a great mixing equipment. They are able to ensure complete interruption free process. In such mixer fluids flow rapidly either from clockwise or anticlockwise direction to give consistency in product quality. All the internal parts are well attached so that internal pressure remains constant. We made such types of internal parts that aids in ideal mixing and increase the quality of the product by adding realistic results. According to the different needs of various clients, they come in a wide range, so try to choose that design which suits best to you. Inline mixers are applied in various applications to get the desired output. They are highly preferred for facilitating the process of reaction engineering, heat transfer and mass transfer. We offer the variety of ranges to meet different purposes with their own unique flow patterns. Along with this Rufouz Hitek Engineers Pvt. Ltd. also offer Static Inline Mixer designs to our clients. Degree of mixing required, ability to be cleaned, appropriateness of scale-up, pressure fall, shear rate, residence time allotment, heat transmission and hold-up volume are some essential factors that actually decided the efficiency of the inline mixers.

...more

Turnkey Systems

We have core competence, diligent team, experience and tested knowledge of site dynamics which enables us to handle the complexities of turnkey engagements. We have a proud track record of effectively executed composite projects involving diverse challenges like Designing & fabrication of plants Designing & fabrication of equipments Site work comprising civil, electrical, piping, controls etc. Instrumentation related jobs, Installation, integration and commissioning of the entire plant and operating system. The most recent turnkey assignment, successfully effectuated bys us, has been for the Solvent Extraction System for the Indian Oil Corporation Limited, at Taloja in the state of Maharashtra. The multi - functional task force we have, ensures professional planning, organising, co-ordination and systematic execution of turnkey Systems. Each turnkey project managed and executed by us carries our stamp of guarantee. At Rufouz Hitek Engineers, Turnkey Systems are given best attention and highest priority because they demand the highest level of professionalism and dedication along with cross - functional capabilities.

...more

chemical process services

� Engineering Services � R & D trial services Engineering Services At Rufouz Hitek Engineers we provide full scale plant engineering services from concept till start-up of a project with comprehensive involvement and support under one roof whether the project is large or small, greenfield or brown-field, re-vamp or modification. With years of domain expertise and experience RHEPL provides end-to-end integrated engineering services to manufacturers & industrial clients globally. Our innovative approach, specialized knowledge on process engineering, exposure to various industry domains and with use of various engineering tools & techniques, we deliver comprehensive solutions for engineering, procurement and construction. Our key engineering design services portfolio includes: PROJECT MANAGEMENT Basic Engineering Detail Engineering Project Engineering Conceptual Design Equipment Fabrication Erection & Commissioning assistance In house Analytical & Data Analysis Design Manual Process Guarantee R & D trial services After extensive R & D and on building collaborations, we have recently diversified into providing process technologies for Oil & Gas Processing, Fractional Distillation, Used Lube Oil Refining Systems etc. On small scale basis we can provide R & D trial for various process like extraction, distillation. Hitek has its own specialty in providing pilot plant for reaction system include plug flow rector for efficient mixing. We have our own set up of extraction pilot plant & others. Pilot Trials Skid Mounted Pilot Plants (Distillation, Extraction etc.)

...moreOpening Hours