woven sack printing machine

140,000 Per Piece

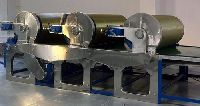

SIX COLOR FLEXO PRINTING MACHINES FOR WOVEN SACK

1,500,000 - 15,000,000 Per Piece

1 Piece (MOQ)

SIX COLOUR FLEXO PRINTING MACHINE FOR WOVEN SACK Features : Ribbed Anti Vibration MS IRON Body for vibration free printing at high speed printing. AC Digital frequency drive.(Optional HMI) Twin High speed Blower with drying system for high speed operation Repeat Print of Plate Cylinder 400mm ~1200mm as standard model. Printing Possibilities (Front + Back) 6+0, 3+3,4+2 Web Guide (Pneumo Hydraulic) - E.P.C Extended Unwinder (Optional) Deco 5 layer Paint for smooth touch Optional Online Gusseting device Surface Winder Optional Auto Tension Controller on Rewinding & Winding

Best Deals from Sack Making Machine

Automatic Woven Sack Bag Cutting and Stitching Machine

Get Price Quote

Automatic Woven Sack Bag Cutting and Stitching Machine manufactured /supplied/Exported by us is designed using latest technologies. Plant is fabricated with the high quality steel and tested before delivery for its performance. Plant performs efficiently for a longer period of time. KEY INFORMATION Production capacity of the machine is 30 to 40 bags/minute Operation of the machine is fully automatic grade Speed of the machine is about 4500 rpm Rated power of the machine is 2 hp Machine body is constructed with mild steel material

woven sack printing machine

Get Price Quote

Corona treater for woven fabrics-Corona treatment system is a very effective way to increase the surface tension of virtually any material. Surface treatment is required for plastic filmsfabrics whose normal surface tension is not sufficiently high to permit good wetting by flexo graphic inks. Corona treatment for woven sacks-PPHDPEWoven sacks fabrics has to be corona treated before printing on flexographic printing machine.

woven sack cutting machine

Get Price Quote

This machine suitable for conventional bag application and is designed for cutting the tubular fabric, bottom folding, sewing and stacking. This new generation machine with servo and PLC controls is designed for fabric width up to 850 mm and cut length up to 1400 mm with speeds up to 30 to 40 bagsmin. depending upon material, width of the fabric, length of bag, number of folds, stitches etc. This bag making machine is most appropriate for working with un-laminated fabric but can also be converted to use laminated fabric. Woven Sack Bag Conversion Line is recognized for delivering optimum support in meeting the production demands of woven sacks. Available under different models with change in specifications and operational features, these woven bag making lines are equipped with two Servo motors to deliver consistent performance support.

woven sack printing machine

Get Price Quote

Corona treater for woven fabrics-Corona treatment system is a very effective way to increase the surface tension of virtually any material. Surface treatment is required for plastic filmsfabrics whose normal surface tension is not sufficiently high to permit good wetting by flexo graphic inks. Corona treatment for woven sacks-PPHDPEWoven sacks fabrics has to be corona treated before printing on flexographic printing machine.

woven sack printing machine

Get Price Quote

Infeed and Outfeed system provided to maintain tension & good registration. Helical Gears for Smooth running and long life.Twin High speed Blower with drying system for high speed operation Repeat Print of Plate Cylinder 400mm ~1200mm as standard model.Optional Online Gusseting device, Surface Winder and Automatic polycut system, Optional Auto Tension Controller on Rewinding & Winding.

woven sacks printing machine

Get Price Quote

Corona treatment for woven sacks-PP/HDPE Woven sacks fabrics has to be corona treated before printing on flexographic printing machine. Corona treater for woven fabrics-Corona treatment system is a very effective way to increase the surface tension of virtually any material. Surface treatment is required for plastic films/fabrics whose normal surface tension is not sufficiently high to permit good wetting by flexo graphic inks. Application : Blown film extrusion single and multilayer for plastic film plants Woven sack roll on- line Flexo printing machine. Extrusion and lamination coating plant for paper industry Sheet line plant Plastic moulded articles Woven sack roll on line flexo printing machine Gum coating on PTFE coat fibre glass cloth PVDC coating on PVC film for pharmaceutical applications.

Woven Sack Sewing Machine

Get Price Quote

When looking to buy several types of machines; one of the most important facts that we, Manhattan Exports give you is to buy the best that you can afford. Giving this statement to our customers, we ensure that an extensive range of Woven Sack Sewing Machine, PP Woven Sack Sewing Machines, PP Bag Sewing Machine, FIBC Sewing Machine, Big Bag Sewing Machine, Jute Bag Sewing Machine, Belt Cutting Machine, Heavy Duty Machine, Heavy Duty Bag Closing Machine, and Note Book Sewing Machine is available with us only at cost effective solutions. We feel proud to be introduced ourselves as one of the top notch Exporters & Suppliers of the industry.

woven sack making machine

Get Price Quote

A prominent supplier of huge range of Woven Sack Making Machine.

Woven Sack Bag Printing Machine

Get Price Quote

Woven Sack Bag Printing Machine, Winders Spare Parts, Shade Card Winder

woven sack printing machine

Get Price Quote

woven sack printing machine, 8 Color Flexo Printing Press Stack Type

PP Woven Sack Machine

Get Price Quote

PP Woven Sack Machine, Blow Moulding Machine, Indenting Agents

woven sacks machinery

Get Price Quote

woven sacks machinery, lamination plants, Lamination Machinery

woven sack machinery

Get Price Quote

woven sack machinery, PP Mat Making Machine, warping machines