Walk In Oven

Vibrating Dryer

CONTINEOUS FLOW VIBRATING FLUID DRYER-ROASTER COOKER Fluidization of wet materials such as tea, grated coconut, spices and any Granular / powder is not possible by air alone. The SAKAV VFBD uses a combination of Vibration and a Special Air Distribution plate to effectively fluidize such materials. Compact design of the SAKAV VFBD enables single pass drying, making it an ideal and fuel efficient drying equipment. SAILENT FEATURES Robust design / Long life Hygienic construction Minimum space requirement Suits any heater / fuel Easy to operate MACHINE DESCRIPTION :- The Machine consist of a Vibratory Conveyor over which is moulded either a gas fired infra red manifold. or an electrical manifold, or any other HotAir Media, steam, Gas etc. The material is fed onto the vibratory conveyor from a feed vibrator controlled by a rheostat. As the material pass under the infra-red burners they are subjected to a continuous vibration in order to turn the material over many times. This enables all the material to receive an equal amount of of infra-red burners can be varied so that the material can be dried, roasted or for various periods, in order that the materials may reach an internal temperature. The hot material are then immediately elevated into an insulated maturing holding bin. where they continue to cook with their own residual heat, for predetermined periods which can be varied as desired. Depending on the final reduction of moisture. A measured quantity of material is fed onto a specially designed stainless steel perforated vibrating plate mounted on an aerodynamically designed plenum chamber. The entire assembly of plenum chamber and perforated plate is suspended on spring and vithrealed with electric Balanced Meter. Hot air from the heat source is sucked in and forced through the plenum chamber by a hot air blower. The plant is complete with feed hopper, electrical control, cooler, insulated maturing holding bind, cooling fan. cyclone and airtrunking. GAS FIRED INFRA RED BURNERS AVAILABLE. OUTPUT :- Output from 25 Kgs. / Hr. to 2 Tones / Hr. Heating Capacity varies from machine to machine depending material, Drying Time & etc. CONSTRUCTION :- All parts in contact with the product are in Stainless Steel constructions. The entire vibrating bed assembly is encased in a rugged self-supporting casing of channel frame construction

...more

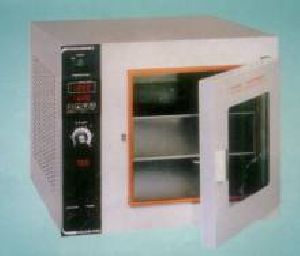

vacuum shelf dryers

Vacuum Shelf dryers provide rapid drying of heat sensitive, air-sensitive & pyrophoric materials, or materials that require drying without agitation. Heat sensitive materials can be dried at low temperatures under vacuum, since the environmental pressure is reduced below the vapour-pressure of the contained water or solvents. Oxidation or Contamination by Air is eliminated. Recovery of expensive solvents can be virtually complete. Hollow Fibers, Medical Devices, Chemical Salts, Fine Chemicals, Dyes, Glandular Products, Pharmaceuticals and Food Extracts (Gluten, Glues, Pepsin), Rubber Explosive, etc. are ideally suited for drying in this manner. Environment Principally, Drying under vacuum is environmentally friendly because the Evaporated Solvents can easily be re-condensed. These solvents can then either be recycled or disposed of without any problem. Drying of solvents in Ex-proof ovens may solve the safety problem in the oven but not the environmental aspect. The solvent vapour is blown out of the oven through the exhaust system Furthermore, there is a risk of uncontrolled mixture formation. Features : A major design feature incorporated in this series of vacuum dryers is the placement of all shelf and manifold connection outside of the chamber, avoiding the possibility that leaks might develop within a chamber and contaminate the product being dried. This feature also simplifies the maintenance of these connection by making access to them more convenient. Charge temperature measuring facility provides exact picture of the process. It measures the temperature directly at charge (material). A PT-100 Temp. Sensor enters the vacuum chamber via connection at the top Rear. "SANDWICH" Type High Thermal efficiency Stainless Steel Shelves with the heat transfer fluid circulation. Even heat distribution through whole shelf surface by baffles within shelves. Chamber walls are heated externally to prevent condensation on the internal walls. Rounded edges in walls shelves and product trays in order to facilitate cleaning and prevent accumulation of dry product residue and practical formation

...more

Vacuum Oven

Warranty : 1 year

Tube Dryers

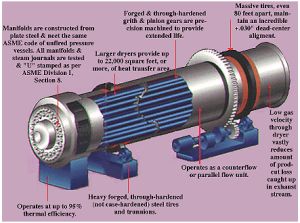

Steam Tube Dryers The Sakav Steam Tube Dryer was developed to dry high moisture organic by-products such as brewer's and distiller's spent grain. Today, this dryer serves thousands of applications, drying and processing inorganic and organic chemicals and other bulk solid materials. The steam tube dryer generally operates at a lower temperature than other dryers and rotates at a slower speed. Material tumbles gently around the tubes which rotate with the shell, unlike the friction forces required by other types of dryers to process material. Consequently, it enjoys a longer life than most dryers and requires very little maintenance. Sakav Steam Tube Dryers have proved superior to other types of indirect-heat dryer installations in which hot gas, rather than steam, is used as the heat source. Maintenance savings alone have often prompted replacement of other dryer systems with the Steam Tube Dryer The Sakav Continuous Seal Steam Tube Dryer offers tremendous advantages for solvent extraction or drying in an inert gas atmosphere. The CS unit's revolutionary design permits material to be processed in a positive or negative pressure atmosphere and alleviates product and gas leakage into or out of the dryer. The dryer is operated as a counterflow unit. Air moves in the opposite direction of material flow. Sweep gas flow is used only to exhaust vapor and other gases created by the heating process, not to dry material. Low sweep gas velocity through the dryer vastly reduces the amount of product entrained in the exhaust stream. During solvent extraction, this not only means significant savings in the size and cost of recovery equipment, but simplifies dust collection requirements and reduces the cost of equipment required to handle the task.

...more

Tray Dryer

Warranty : 1 year

Hot Water Dryers

Gas, Electric, Steam And Hot Water Dryers. Batch Type And Conveyor Dryers. Ideal for shelf processing applications such as Drying, Dehydrating, Pre-heating or any other heat processing of large or numerous parts at 1500C Applications The SAKAV Dryer has been developed to offer an economical answer to a wide range of applications like Animal Feed Calcium Carbonate Catalysts Ceramic paper and board Cereals Charcoal Briquettes Chemicals Clays Collagen Casings Extruded Products Fertilizers Food and Ingredients French Fries Glue Natural and Synthetic Fibres Polyurethane Foam Silica Gel Soap Starch Synthetic Rubber Vegetables SAKAV offers Dryers in standard sizes or can be custom built to suit specific requirement Dehydrators De-watering Dryers High Speed Suction Dryers Pre-dryers for the food industry Product assessment Services & Spares Test Equipment Training of Customer Staff Single Conveyor Dryer Multi-Stage Single Conveyor Dryer Multiple Conveyor Dryer Heavy Duty Conveyor Dryer Multi-Purpose Vegetable Dryer FEATURES Hygienic and Powerful Fan Units Case less Plug type Fans to specific design Guarded for Safety yet Fully Cleanable New HIFLO direct coupled fans upto 55 kW Band Cleaning - enables a wide range of coated products to be handled (Optional) Variable Drive Speed - controls the product residence time accurately. Band speeds from 1.5 to 4.5 metres /min Hygienic Design - achieved through ample access doors for cleaning and maintenance together with stainless steel contact parts Efficient Design - has been achieved by the re-use of air. Lower air velocities can be used to minimize product damage Variety of Belt Types - means a greater range of product shapes and sizes can be handled whilst allowing maximum airflow External Infeed Section - helps to remove fines before product enters the dryer Construction - typically manufactured in painted mild steel with stainless steel contact parts, a totally stainless steel option is available. Insulation is 50mm thick rockwool Product Tumbling Action - as product transfers from a one conveyor to the next, assists even drying. Air/ Vapour Tight Construction Excellent Air Flow Control Multizone Temperature Profiles Flexible Feed Rates Gentle Handling of Materials Integral Cooling Options DESIGN - MANUFACTURE INSTALLATION AND TESTING Design: Fully experienced design engineers using the latest AutoCAD systems Process Development: Design and Product development for individual customer requirements. Dedicated Commitment We are committed to supply the right equipment for the individual need of our clients, on the basis of our continuous development and improvement strategy. SAKAV is capable of supplying the most efficient drying systems, and continually upgrade and extend the range of applications and processes. High priority is given to system control, ease of access for cleaning and maintenance. Our scope of services comprise, process technological dimensioning on the basis of product examination, in many cases carried out at our premises using one of demonstration dryers available

...more

Thermostatic Water Bath

Double walled construction, inner and outer chamber made of stainless steel with concentric rings and lids, with thermostatic control. Temperature range: 50C above ambient to 950C Accuracy: + 20C The bath can be raised to boiling temperature with thermostat set at maximum. Universal Water Bath Construction : This water bath made from single wall made of stainless steel. It is designed to meet almost all requirements of Pathological, Microbiological, Chemical, Physical and other Laboratories.

...more

Tempering Furnaces

Warranty : 1 year

Frequency : 50 HZ

Tempering Bench Furnaces

Electric Tempering Furnace can be combined with Electric Bench Furnaces or Inert Atmosphere Bench Furnaces to produce a space saving, over and under, heat treating and tempering furnace combination. The top chamber with its manually operated vertical lift door can be selected from among four sizes of 11000F and 12000C Bench Furnaces described on Bulletin BF-710 or Inert Atmosphere Bench Furnaces described on Bulletin BF-720. The Quench Tank is a free standing unit available with electric heat. STANDARD FEATURES Controls - Digital, microprocessor based, thermocouple actuated, indicating temperature controller - On-off heat switch - Easy-to-see pilot light Safely Equipment Adjustable, thermocouple actuated, manual reset excess temperature controller Separate heating element control contactor Door interlock switch turns off power to heating elements and blower when door is opened; restores power when door is closed Construction Recirculation blower located in back wall Heavy gauge aluminized steel cabinet with enamel finish Brushed stainless steel control panel face Designed to support heat treating furnace Well insulated, side-hinged door High temperature alloy heating elements supported by rugged ceramic plates Energy-saving lightweight ceramic fiber insulation reduces operating costs Fast heat-up Heating elements located on sidewall and roof for excellent temperature uniformity throughout workspace Ceramic hearth tray 1 year limited warranty Optional Quench Tank Expanded metal loading basket Use with water, oil or synthetic solutions ½ HP direct subway grate basket support Optional electric heat All equipment fully assembled and individually factory tested STANDARD EQUIPMENT Standard Electrical Characteristics -230 Volts, 3-phase, 60 Hz -Other electrical characteristics available Wall insulation, 7" thick, consisting of -1" of 12500C,8 lbs /ct ceramic fiber blanket -2" of 9250C, 4 lbs /CF ceramic fiber blanket -2" of 10500C 15 lbs/CF block insulation -2" of 6750C rockwool insulation Floor insulation, 6 ½ " consisting of: - 4 ½" of 12500C insulating firebrick - 2" of 6750 C 18 ½ lbs/ cf. block insulation Electric Models Safety devices as listed on the front of this bulletin. Heating element contactors electrically interlocked with door to shut off power to heaters as door opens and restores power when closed. High temperature alloy coiled wire-heating element supported in alloy rack, Heating elements located in heat chamber upstream of the recalculating blower. Exhaust outlet 4'" diameter. Gas Models - 1,000 BTU natural gas at 2-psig pressures. 1" NP inlet up to 800,000 BTU/HR - Other gas characteristics available Safety devices as listed on the front of this bulletin. Automatic preignition purge period and push button electric ignition contributes to ease of operation. Modulating gas burner fires into chamber upstream of the re-circulating blower. Gas burner protected with electronic flame safety relay. Door interlock switch drives main burner to low fire when door is opened and restores control when door is closed. Exhaust outlet 6" diameter. Furnace shell is made of 3/16" thick steel plate reinforced with structural steel. Doorsill constructed from firebrick to protect furnace during loading. Stainless steel grid at bottom of workspace to distribute loading. Soft insulation on door provides an excellent heat seal by pressing against the vestibule refractory and ½" thick steel front plate. Exterior painted with Trilite Green enamel. Each features completely wired side access control panel assembled on the furnace enclosing terminals for incoming power, temperature controllers, push buttons and pilot lights. Electric Door Door pivots upward above furnace, clearing front for easy loading. In the closed position, full door weight seats door firmly against furnace face. Structural steel pivot arms are supported at furnace sidewalls by bearings and connected to a heavy-duty electro-mechanical actuator. The door is controlled by a switch at the furnace control panel. Air Door Door rises vertically in front of the furnace hanging from heavy-duty roller chain, sprockets, shaft and pillow block bearings. In the closed position, rollers at the sides of the door engage support brackets to force the full door weight against the furnace face. Large diameter air cylinder rotates support shaft to lift the door. The door is controlled by a manual air valve with supply filter, lubricator and regulator. ADDITIONAL EQUIPMENT AVAILABLE Programmable Temperature Controller, microprocessor based, digital indicating, thermocouple actuated, in lieu of standard controller.........................................................PTC3 Recording Thermometer, thermocouple actuated, 24-hour, 10" diameter circular chart used in conjunction with standard controller.............RT Programmable Recording Temperature Controller, microprocessor based, thermocouple actuated, digital display, 24-hour, 10" diameter circular chart, in lieu of standard controller ....................PRTC3 Digital Timing System, incorporated into standard temperature controller, 99 hour 59 minute range, starts timing at temperature set point and shuts down furnace at end of set time .........................DTS3 Shut Down Timer, with continuous "hold" feature 1,5, 10 or 30 hour range.............SDT Batch Timer, for uniformly timing batch operations. Continuous alarm with door interlock; alarms at end of preset time period until door is opened or timer reset. 1,5,10 or 30 hour range........................ BT Inert Atmosphere Construction, available on electric furnaces only, includes continuously welded furnace shell, inert atmosphere gas inlet and outlet, sealed terminal boxes, high temperature door gasket....IAC Inert Atmosphere Inlet Piping, complete with indicating flow control and gas valve. Specify atmosphere...IA

...more

Temperature Control

A thermostat controls temperature at any point from 50C above ambient 950C. The accuracy of control is + 10C upto a temperature of 600C and + 20C at a higher temperature and is provided with a pilot lamp. The heating element and the thermostat stem are protected by a perforated false bottom. Available in two Sizes : 30.0 x 22.5 x 17.5 cm 45.0 x 30.0 x 17.5 cm Accessories at extra cost: (a) Pyramidal Limited (b) Drop-on-Lid 1. 4 holes of 7.5 cm 2. One hole of 12.5 cm (Central) 3. Double of the above Racks (S.S. Plated) • Kahn Racks - 40 tubes • Wassermann Racks - 48 tubes • Agglutination Rack - 42 tubes

...more

spray drying systems

A DECADE OF EXPERIENCE SAKAV, established in 1985, has developed and supplied a wide range of SPRAY DRYING SYSTEMS to the Chemicals, Dyestuffs, Ceramics, Food, Polymers and Pharmaceutical Industries in India and Abroad. With its vast specializes experience, resources and innovative technical know-how, SAKAV offers the most appropriate systems for all Spray Drying requirements designed and delivered by Sakav incorporate practically every conceivable combination of system components to meet a variety of product requirements. THE SPRAY DRYING OPTION A spray drying system employs a single process to convert a solution/slurry into a powder. The liquid is atomized, in a specially designed Drying Chamber, into a stream of hot air to evaporate the solvent. The dry powder is then separated from the air stream. Sakav custom designs a system to suit the product quality, feed conditions, heating source available and the local environment norms. The chamber geometry, spray pattern and the air flow distribution have a decisive influence on the product characteristics. Each system is a harmonious combination of individual process sections of Air Heating, Feeding, Atomization, Powder Collection and Dust Separation. The wide variation of combinations handled by SAKAV are given in the table below - ROTARY ATOMISER SAKAV with its in-house design capabilities ha built and supplied a range of Rotary Disc Atomizer. These are belt driven units with standard electrical motors. A number of models are available with wheel diameters of 100mm to 350mm and are suitable for capacities from 5 lit/hr to 10,000 lit/hr Various configurations such as orifice, pin, vane with stainless steel and ceramic wear parts are available. A variety of lubrication systems starting from continuous drip to fully automatic forced lubrication systems can be provided. Speed variations are achieved by changed pulleys or variable frequency drivers. TEST FACILITY Fully equipped dedicated Pilot Spray Dryers are available for conducting trials on customers samples and simulation of ideal drying parameters for individual products. Assessment of their physical properties such as moisture content, approximate particle size distribution and bulk density. Testing is an on-going process and SAKAV has, over the years, built-up a large data base for a wide variety of products. THE CHAMBER OPTIONS The chamber configuration plays an important part in meeting the end product requirements. As is apparent from the table there is an endless number of possible combination. Some of these have been depicted below. FLAT ROOF This is the most widely used configuration of spray chamber with flat roof construction. Co-current swirling air flow pattern is used in conjunction with centrifugal atomization. Generally used for producing a uniform fine powder. Dry powder can be collected partly under the chamber and the fines from the cyclone. Alternatively a single point collection under the cyclone can be provided. Can be adapted for nozzle atomization with an add-on air distributor. TALL FORM - BUSTLE The standard Tall Form Bustle construction with co-current linearized air flow pattern is sued with pressure nozzle atomization systems. The dry product is usually coarser than centrifugal disc atomized product. The bustle construction enables separation of coarse fraction below the chamber and the fines can be collected from the cyclone. This configuration is deal where fines recycle is used for product agglomeration. TWO STAGE A configuration consisting of Tall Form Spray Chamber with a second stage Fluid Bed Dryer is used for special applications. This configuration is used for products requiring longer drying times which cannot be provided in Spray Chamber. This occurs when a coarse product has to be dried to a very low moisture content or when the product to be dried is hygroscopic in nature

...more

shrink packing ovens

professional packing for your product. Easy to operate, low maintenance, economical cost of operation. features high effiecncy heaters cooling blower simple and efficient speed control perfect temp.control custom built shrink wrapping system avalible . optional extended tunnel infeed/outfeed pressure rollers above extened tunnel outfeed. teflon netting belt conveyor. adjustable clearance in height.

...more

sesame Roaster Machine

65,000 Per Piece

01 Piece (MOQ)

Automation Grade : Automatic

Fuel : LPG

Serological Water Bath

This is a double walled serological bath with outer and inner wall made of stainless steel. The gap between the walls is filled with glasswool to minimize loss of temperature. A thermostat, at any point from 50C, controls the temperature automatically above room temperature to 600C with an accuracy of + 0.50C and operates on single phase AC current. A built-in pilot lamp is also provided indicate the working of thermostat. Kahn racks to hold 40 tubes, are available at extra cost. The racks are made of stainless steel or brass.

...more

Rectangular Water Bath

Rectangular Water Bath Single walled made of stainless steel with concentric rings and a lid are provided on hole. The bath has a built-in constant level arrangement. Suitable for use on 230 Volts AC single phase supply

...more

Rotary Dryer

Rotary Cascade Dryer

ROTARY CASCADE AND ROTARY LOUVRE DRYER AND COOLER 1500 KGS.lHR. BONE MEAL COCURRENT ROTARY DRYER SAKAV DRYERS handle all types of materials. Recognising that virtually every drying application is unique. Each Rotary Cascade Dryer is purposely designed to meet specific matenal characteristics by analysing the client's process requirement. the correct design solution is assessed & selected by. Designed for Bulk drying of: Minerals· Metal Ores - Fertilisers· Foodstuff - Chemicals -Industrial & Domestic waste. WIDE RANGE OFF GRANULAR MATERIAL Aggregates' Aluminium Oxide' Ammonium nitrate' Ammonium sulphate' Andalousite Animal manure Barium Carbonate' Basic Slag' Bauxite' Benlonil - Blanose Bone meal Bone Powder' Borates Calcium Chloride' Carbon Black pellets' Cement Raw meals' Chicken waste' Chrome Ore' Citric Acid Clay earth' Clays' Coal' Cobalt oxide' Coke Breeze Copper Concentrates' Copper Lead tin alloy· Copper Slag· Copper Sulphate' Copper wastes Cotton seed' Crushed Glass' Crushed Marble' Crystals' Dextrose monohydrate' Dicalcium Phosphate' Egg shell' Feldspar- Ferrile Ferronickel Fertilisers Flint Chips' Garbage wastes Gypsum' Gypsum' Heamatite Herbicides' Herbicides' Ilmenite' Industrial wastes' Kaolin Lardstone Limestone' Maqnesiurn Sulphate' Maize germs' Montmorillonite clay· Nickel Oily chlorate' Potassium Nitrate' PPT Silica' Quartz' Rawa Refractories' Rock Phosphate Rubber' Salt· Sand' Sludges' Sodium Chloride' Sodium monoglutamate Spath fluor' Sugar Talc' Titanium Dioxide' Titanium oxide Urea' Wine tarter' zince oxide. FEATURES • HIGH AUTOMATION • LOW MAINTENANCE • CONTINUOUS OPERATION • LOW OPERATING COST OPERATING TEMPERATURE :- 60°C to 1OOO°C. CAPACITY :- 5 TPD TO 150 TPD SIZE & MOISTURE :- Capable of Handling different product particle size & moisturecontent. SYSTEM Drying / cooling is achieved by passing the material to be processed through a rotating cylinder through which also passes a current of tempered air. Lifters/flights or louvres in the case of rotary louvre dryer, are fitted to the Internal surface of the cylinder to give intimate contact between product and drying or cooling air stream. In Rotary Louvre dryers the material IS not lifted and dropped through the drying air stream, therefore less product breakdown occurs. Rotary Louvre dryers can also be arranged for multi-stage drying, or drying and cooling in one Unit. DRYER PRINCIPLE Co-current Flow Rotary Cascade Dryers, sticky and heat sensitive materials, since the wet material IS exposed to the highest temperature gases, the initial heat transfer rate is very high, rapidly evaporating surface moisture. The Immediate and dramatic fall in gas temperature prevents a sudden Increase in the matenal and shell temperatures. The final product is in contact with the lower temperature gases enabling the moisture content to be readily controlled thereby avoidrnq over-drying. Counter-Current Flow drying in a Rotary Cascade Dryer gives lower product moisture than co-current flow for a given inlet temperature. However, its use with heatsensitive rnatenals IS limited since the dryed product comes into contact with the heating medium at its highest temperature. It is suitable for application where an extremely low moisture content is required or where a higher product temperature is anadvantage. HEATING MEDIUM Gas. Diesel, oil, electric, stream. The drying gas are provided from either a direct fired furnace or an indirect heat exchanger within the range 100 to 1000 C using solid, gaseous or liquid fuel. Only products of combustion or indirectly heated gases enter the Rotary Cascade Dryer. This prevents surface contamination while reducing the risk of damage or fire when handeling more sensitive materials. A two fan balanced draught system IS used to provide the maximum degree of control & flexibility. In arrangements and the drying gases are provided by a locally mounted burner projecting the flame down the centre of the dryer through which the material cascades. This design gives even greater thermal efficiency due to the higher temperature differential, the direct flame contact and the radiation effect, when processing materials which can withstand high gas temperatures without deterioration. CONSTRUCTION Carbon, Stainless or custom alloy steel plate, with external reinforcing bands for fitting of tyres and drive rings. Flights and lifters or louvres are welded or bolted internally. Confifuration is determined by application. DRIVE Drum is rotated by an electric motor through V-belts, gearbox, pinion and either heavy duty chain to a chainwheel or spur gear drive ring bolted around the dryer drum. For high temperature operation, tangent plates are utilized to allow for differential expansion. CLOSURES & SEALS Ends of drum may be enclosed by carbon or alloy steel fabricated end plates or hood With Inlet/outlet chutes and suitable seals Note : Dimensions and the other data of the Rotary Dryers depend on the material properties, water content. dryness, drying capacity, etc. The values of motor horsepower given in the table are those required to rotate the rotary dryer alone. The figures do not Include the horsepower requirements to operate the exhaust, burner material feeder etc.

...more

pit furnaces

Warranty : 1 year

Voltage : 230 volts

Muffle Furnace

Low Temperature Incubators

Whether in biotechnology, zoology & botany, whether in the pharmaceutical, cosmetic, food industry, or medicines, test at temperatures between room temperature & ±0°C are gaining importance. Here it is not only a question of excellent thermosetting accuracy but only a unrestricted time - dependent programming, of optimum, reproducibility & of documentation of the important test processes. In close co-operation with discerning users we have included these set new standards but also impress with a particularly high level of functionality. CONSTRUCTION The outer cabinet & inner chamber is manufactured from High Quality Polished Stainless Steel & regular models from quality mild steel finished with hardwearing powder coated. The cabinet is insulated with best quality fiber glasswool or polyurethane foam. Double walled insulated door allows full access to the working chamber HEATING AND COOLING Heating is achieved by Low Surface Temperature Heaters. And they are located in side duct close to circulation fan. Hermetically sealed compressor coupled with evaporation coil and fan cooled condenser provides cooling below ambient temperature. CONTROL SYSTEM State of the Art Microprocessor based temperature controller controls temperature. Temperature is independently sensed by PT-100 Sensor. Microprocessor takes care of any overshooting or undershooting of temperature. Control system also controls automatically cooling and heating devices i.e. Heaters and Compressors. Cyclic Temperature Programming is also available as an option. The Controller Optionally allows taking printouts of temperature with real time clocks. AIR CIRCULATION A powerful fan located in the side duct of the working chamber re-circulates the internal atmosphere. A perforated false floor ensures an even vertical airflow throughout the working chamber. The air traveling upwards is extracted by a Fan and is guided through the side duct comprises of an electric heater, a heat exchanger (cooling coil). Day - Night Simulation

...more

Loading Trucks and Shelves

INSULATED FLOOR AND TRUCK TRACKS Standard Walk-In Ovens include a steel plate floor and provisions for a custom installed insulated floor. Floor plate is " thick in ovens up to 72" wide x 120" long; thick on wider models. A doorsill at the front edge of the floor plate maintains doorway rigidity and provides sealing surface for the oven doors. The doorsill is 2" high on 2750C and 3500C ovens; 3" high 4000C ovens. At no charge, the doorsill can be eliminated, door lengthened and equipped with drag seals. This arrangement provides a floor level entrance to allow loading by hand truck, fork lift truck or by loading equipment to varying wheel spacing. When loading with an over truck, installation of truck wheel guide is recommended. This allows the doorsill to remain across the work space opning. Floor level truck wheel guide track openings beneath the doors. Truck wheel guide track width and centerlines may be specified to suit existing equipment or to be used with a loading track from the front of this bulletin. Guide tracks are generally wider than track wheel width. If not specified, tracks are provided 2 wide on centerlines 12" less than work space width. Truck Tracks to allow loading at factory floor truck loading limited to distributed floor loading of 100 Ibs per square foot level, flared at the front for easy entrance of wheels, includes truck track seals on door to close off track opening ..........................TT Insulated Floor with Recessed Truck Tracks provides reduced heat loss and improved temperature uniformity of insulated floor plus allows loading at factory floor level.......................................................................................................................IFRTT Insulated Floor with steel plate over, 2" for 2750C and 3500C, 3" at 4000C, minimizes heat loss and improves temperature uniformity near floor level, rated at 100 Ibs per square foot distributed loading..........................................................................IF Insulated Floor with Surface Truck Tracks use where oven will be recessed into the factory floor or loading with an extended ramp, includes drag seals on the oven door. Total........................................................................................................................IFSTT ADDITIONAL EQUIPMENT AVAILABLE Programmable Temperature Controller, microprocessor based, digital indicating, thermocouple actuated, in lieu of standard controller......................................................................................................PTC3 Recording Thermometer, thermocouple actuated, 24-hour, 10" diameter circular chart used in conjunction with standard controller..........................................................................................................RT Programmable Recording Temperature Controller, microprocessor based thermocouple actuated, digital display, 24-hour, 10" diameter circular chart, in lieu of standard controller..........................................................................................................PRTC3 Digital Timing System, incorporated into standard temperature controller, 99 hour 59 minute range, starts timing when temperature reaches set point and shuts down oven at end of set time ..............................................................................DTS3 Shut Down Timer, with continuous "hold" feature, 1,5,10 or 30 hour range............................................................................SDT Batch Timer, for uniformly timing batch operations, Continuous alarm with door interlock, alarms at end of preset time period untill door is opened or time reset. 1, 5, 10 or 30 hour range....................................................................................................BT Automatic Door Switch, turns off blower and heat when door is opened. Restores blower and heat on electric models, blower only on gas models, when door is closed................................................................................................................ADS Powered Forced Exhauster

...more

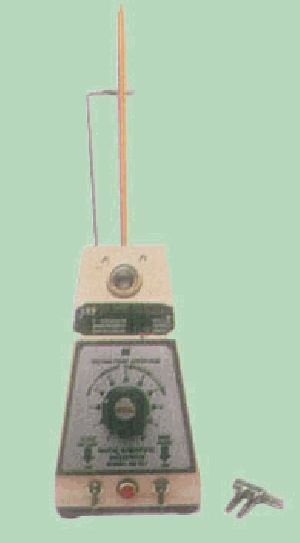

Melting Point Apparatus

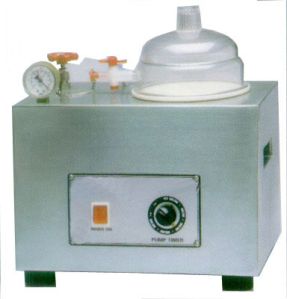

leak test apparatus

Be first to Rate

Rate ThisOpening Hours