water softner plant

Custom built water softner plants with flow Capacities ranging from 0.7m3 / Hr to 12m3 / hr with an output per regneration ranging from 8.1m3 to 20.3m3 max. working pressure 3.0 kg / cm2.

...more

water scrubber

The equipment is installed between the chemical purifier and the high-pressure compressor which helps to remove additional impurities from the gas if any.

...more

water level control

If excessive water enters the generator to cool it and the water level goes above the high level mark, the water-level control instrument will immediately discharge the excessive water thus maintaining the water between the acceptable high and low level marks.

...more

Valves for cylinders

Oxygen / Nitrogen / Acetylene / Argon Cylinder valves with SS304 spindle & Teflon. This cylinder valve is fixed to a gas cylinder by screwing & its essential functions are as under : – To enable filling of gas into the cylinder.– To ensure proper storage of the gas – inside the gas cylinder.– To release the gas as and when – required.– To act as a safety device for the cylinder if valves are provided with safety.

...more

psa plants

The oxygen generators, consists of two absorption vessels and filled with molecular sieves are alternatively charged with compressed air to absorb the nitrogen. Salient Features Substantially lower operation cost. Based on economical, reliable and proven technology. PSA Nitrogen Gas PlantIt’s easy to operate and produces nitrogen from atmospheric air and therefore the cost of nitrogen generation is minimal. Salient Features Start-up time only 5-minutes to get nitrogen of desired purity. No petroleum fuels required – only electrical power and cooling water needed for nitrogen generation. Fully automatic start-up by single push button. Very compact skid mounted units supplied, duly assembled from our factory. Life of molecular services guaranteed for 10 years on continuous operation basis.

...more

oxygen plants

Oxygen Plant

Oxygen / Nitrogen Liquid Pump

The liquid pump is a horizontal reciprocating pump. It can pump cryogenic liquids such as Liquid Oxygen, Nitrogen and Argon upto 165 Kgm/Cm2 pressure normally and 250 Kgm / Cm2 pressure in special cases. The pumps are simple and requires least maintenance.

...more

Oxygen Generator

nitrous oxide plants

Nitrous Oxide is produced by heating Ammonium Nitrate to a temperature of 2500C. Ammonium Nitrate is decomposed in the process to give a mixture of Nitrous Oxide & super heated steam. At the same time impurities are produced including Ammonium Nitrate fumes, Nitrogen & other oxides of Nitrogen. The steam & impurities are removed by scrubbing with water, caustic soda and sulphuric acid in sequence Nitrogen present in traces is removed by bleeding from the top of storage vessels where Nitrous Oxide is stored, after compression by a compressor

...more

Molecular Sieve Battery

This is a battery of two vessels filled with Molecular Sieve type 13-X to absorb Carbon Dioxide and Moisture from process air. One vessel will be online and the other will be regenerated by Dry Nitrogen. Regeneration Heater is also provided.

...more

liquid oxygen pump

The liquid pump is a horizontal reciprocating pump. It can pump cryogenic liquids such as Liquid Oxygen, Nitrogen and Argon upto 165 KgmCm2 pressure normally and 250 Kgm Cm2 pressure in special cases. The pumps are simple and requires least maintenance.

...more

liquid oxygen plants

Certification : BVI,SGS

Voltage : 415,380

After-Sales Service Provided : Engineers available to service machinery overseas

Condition : New

...more

Liquid Gas Cylinders

LGC’s are small liquid cylinders with in built pressure building & evaporating coil to allow both gas as well as liquid withdrawal. It can be transported to & from customers site with liquid filled in just like high pressure gas cylinder. This facilitates larger quantity of product transfer in liquid form than in Gaseous form. It is ideal for Liquid N2, Oxygen, Argon CO2 & N2O.

...more

Hydraulic Cylinder Testing Station

Gases like oxygen and nitrogen are filled in seamless steel cylinders at high pressure ranging from 150 to 200 bar. Such cylinders are also subjected tovarious weather conditions and andling during use at consumer’s place as well as transport, loading and unloading. Essentially, the cylinders are made of a material that has a flexibility of expansion and contraction during pressurization. For various reasons this flexibility of expansion and contraction begins to deteriorate over a period of time. Similarly, on account of other conditions such as filling, handling, transportation and shop floor conditions, there are chances of weight reduction over a period of times. It may also develop certain other defects normally rendering a cylinder unsafe for use. Globally such cylinders are required to be periodically tested for visual damages, weight loss of elasticity. In view of the dimension of damage,which can be caused by a bad cylinder, being known, most people prefer to test these high-pressure cylinders periodically. We provide a complete set-up of equipment for conducting a dependable and assured hydraulic test for such cylinders.

...more

High Pressure Control

If all the gas generated cannot be drawn in by the compressor and passed on to the filling manifold, either due to low capacity of the compressor or fast generations, gas pressure will gradually build in the generator. When the gas pressure reaches a predetermined level (about 0.5 kg /cm2) carbide charging will be cut off automatically and further generation of gas is stopped. There is no expensive gasholder with the SANGHI Acetylene Generator. This item alone will reduce the investment on such a plant. Further, as the gas generated is always at a positive pressure, the pumping cost is also reduced. Since the generator is constantly at a positive pressure, (once the plant has been purged with Nitrogen) no air enter the system,and it is this feature which makes “SANGHI” Plant inherently very safe.

...more

Gas Cylinders

We offer gas cylinders for various gases – Oxygen, Nitrogen, Argon, Carbon Di-Oxide, Hydrogen, Helium etc. with working pressure from 150 bar to 250 bar.

...more

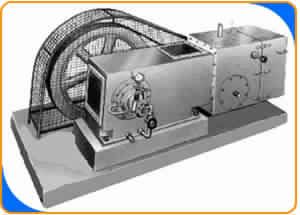

gas compressors

This is a reciprocating machine, with crank gear, piston rod, piston, cylinders. The machine is used for building up pressure of Oxygen, Nitrogen, Nitrous Oxide gas for filling the gas into Cylinders. These are available in various capacities and consist of following : Control Panel consisting of Pressure Gauge for All the Stages and Oil Pressure, and manual unloading Valves, Gas Coolers after all the three stages, Safety Valves for all the three stages, N.R.V. at Delivery, Belt Guard, Tool Box, Flywheel, Fiber Buckets for all the three stages, Motor Pulley.

...more

Foot Mounted Air Compressor

Air Compressor – Type – Reciprocating, Horizontal, Balance opposed, water jacketed, 3 / 4 / 5 stages, depending upon operation cycle. The air compressor is complete with interstage coolers, separators, motor and starter.

...more

Filling Manifold

This consists of a battery of 60 filling connections to connect to the gas cylinders. Non- return valves are provided in various sections of the pipeline to the filling manifold. These non- return valves are extremely important for the safe operation of the plant and should be periodically cleaned to remove rust and scales, (iron cause fire). The cylinder filling pig tails (flexible hose pipes) should also be periodically cleaned to ensure that they; do not burst during filling operation, (if they do burst, a fire would ensure due to sudden discharge of Acetylene).

...more

expansion engine

Expansion Engine is a vertical reciprocating machine which can expand air adiabatically from operating air pressure to 5 Kgm / cm2 to produce the required cold for the Oxygen / Nitrogen plant. It greatly helps to reduce power consumption.

...more

Chemical Purifier

This consists of two layers of regenerative chemicals,which remove additional impurities. The purifying agent may be reactivated for re-use by the atmosphere air. For continuous operation one extra charge of chemicals can be kept in open wooden trolley.

...more

carbon dioxide plants

The process of purifying CO2 is obtained from burning of fuel, using MEA (Monoethanolamin) in a aqueous solution which has been known for quite some time. The plant uses a modernized process by which high purity and food quality CO2 can be obtained. The plant has the latest automatic control equipment and is easy to operate and requires very little maintenance. The CO2 containing combusion gases passes through a pre-cleaning stage and is brought into contact with an aqueous MEA solution which absorbs CO2. Afterwards, the CO2 gas is desorbed from this solution and compressed to the required pressure using special compressors. This is followed by cleaning, drying and final cleaning stages of CO2 gas which is then liquified and filled in a storage tank.

...more

Air Seperation Unit

Air Seperation Unit / Cold Box consists of Distillation Column with Heat Exchangers for heat transfer between the incoming air and the out going cold Nitrogen and Oxygen. It is equipped with Expansion valves for controlling the operation of the plant. Control panel for the cold box is provided with the plant. Defrost heater for thawing plant is also provided on the cold box. It is also equipped with liquid oxygen pump which is a single cylinder equipment and delivers Bone-dry Oxygen upto pressure 165 Kg/Cm2. Cold box is insulated withperlite for minimizing cold losses and reducing power consumption.

...moreBe first to Rate

Rate ThisOpening Hours