Znc EDM Machine

CNC Series The first ISO 9002 approved & recognized EDM manufacturer in Taiwan. Friendly operation with quick start manual to shorten the operator training hours and increase operator efficiency.

...more

wire cut edm filter

Shape : Cylindrical

Usage : Industrial

tool room accessories

Solid carbide cutters • Grinding, EDM machine accessories • Clamping tools for CNC milling machine and lathe machine • Milling machine accessories • Boring tool, tapping chuck, spindle, revolving center, shank etc. • Tool holder, punch grinder, vises, mechanicalhydraulic vises • Chuck, electro magnetic chuck • Dividing head, angle block • Measuring instruments, etc. Matchling tooling co. can supply inspection instruments made in Swiss, Germany, Japan, Taiwan etc. Matchling’s philosophy: “We ensure high quality in our products at reasonable price towards our worldwide network, we build over the decades… attaining client’s satisfaction is our main priority.” Matchling can supply more than 10000 different kinds of products. Most of the items are kept in stock to satisfy the customer’s urgent need.

...more

Taiwan Make High Performance Vertical Machining Center

The Control System is Fanuc 0i MB Package 'B' type. • Linear Guide ways is provided for X, Y, & Z axes. • The Axes Motor and the Ball Screws are directly coupled. • MPG and Rigid Tapping are provided as standard. • For all the 3 axes ball screws is of C-3 class pretension. • Screw type Chip Conveyor is provided. • Automatic Chip Flushing System is provided. • Spindle is provided with 4 pieces of angular contact ball bearings and properly preloaded. • Heat Exchanger for Electric Cabinet is provided. • Fully enclosed Splash Guard is provided.

...more

profile grinders

Longitudinal slideways. High precision heavy duty spindle design . Automatic lubrication system. Stable feed , superior accuracy. Smooth and accurate wheelhead movement. Automatic wheel dressing with. Compensation . Computer-Aided engineering . Spindle head counterweight balance system. Hydraulic system temperature regulator

...more

Hydraulic Wire Cutting Machine

Hydraulic Surface Grinder Machine

600,000 Per Piece

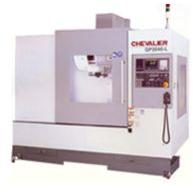

Brand Name : Chevalier

EDM Filters

Higher cutting speeds • Faster wire cutting to the final dimension • Reduction of secondary operation • High quality surface finish • Good reproducible workpiece accuracy • Stable conductance of the dieelectric fluid • Reduced consumption of hte ionisation resin • Reduced machine wera. • Reduced maintenance costs.

...more

die spotting press

Conventional Lathe Machine

Cnc Wire Cutting Machine

Versatile and economical for General Purpose High level of flexibility with low running cost, the ideal machines for any EDM work shop. Versatile and economical for General Purpose High level of flexibility with low running cost, the ideal machines for any EDM work shop.

...more

cnc wire cut machine

Designed by an experienced and passionate team of engineering experts, AMS is proud to present the new AW-Series -- the pinnacle of modern wire cutting. Built using the world's most advanced technologies and highest quality materials, the AW-Series provides your highest performance and best looking results yet. AMS's new AW-Series is a definite "must-have" for the wire-cutting expert!

...more

cnc edm machine

Versatile and economical for General Purpose High level of flexibility with low running cost, the ideal machines for any EDM work shop.Versatile and economical for General Purpose High level of flexibility with low running cost, the ideal machines for any EDM work shop.

...more

CNC Cylindrical Grinding Machine

1 Stable and Rigid Spindle Head (1) The spindle runs on precision bearings, assuring maximum spindle stability. It guarantees outstanding accuracy for external and internal diameter grinding and face grinding. (2)The spindle head swivels +90°~-30°. (3)The spindle head on the 20 series machines provides variable speed changed by frequency inverter. (4)The spindle head on the 32 and 42 series is driven by servomotor, providing variable speed. 2 Precision Wheel Head (1) The grinding wheel spindle is precision machined from high quality alloy steel SNCM-220, normalized, tempered, carburized and sub-zero treated, precision ground and mirror-effect treated. Hardness reaches to over HRC 62°. No deformation, maximum wear resistance and lifetime accuracy are assured. 3. Special Hydrostatic Bearing (1) The wheel spindle runs by using a special hydrostatic bearing and is especially ideal for precision grinding work. It features high speed, no friction between metals, no heat generation, deformation-free, extra high accuracy and continual use. 4. Advanced Hydrostatic Lubrication System (1) The slideways of the table and the wheel head are lubricated by an advanced automatic hydrostatical lubrication system. This provides various features, such as extremely smooth movement, added feed accuracy and superior grinding accuracy.

...more

Chevalier High Speed Compact Vertical Machining Centre

The Control System is Fanuc 0i MB Package 'B' type. • Linear Guide ways is provided for X, Y, & Z axes. • The Axes Motor and the Ball Screws are directly coupled. • MPG and Rigid Tapping are provided as standard. • For all the 3 axes ball screws is of C-3 class pretension. • Screw type Chip Conveyor is provided. • Automatic Chip Flushing System is provided. • Spindle is provided with 4 pieces of angular contact ball bearings and properly preloaded. • Heat Exchanger for Electric Cabinet is provided. • Fully enclosed Splash Guard is provided.

...more

wire cut filters

Higher cutting speeds • Faster wire cutting to the final dimension • Reduction of secondary operation • High quality surface finish • Good reproducible workpiece accuracy • Stable conductance of the dieelectric fluid • Reduced consumption of hte ionisation resin • Reduced machine wera. • Reduced maintenance costs.

...moreBe first to Rate

Rate ThisOpening Hours