food plant pumps

Get Price Quote

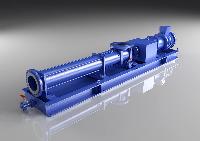

Low Pressure Screw Pump

500 Per Piece

Best Deals from Screw Pumps

Positive Displacement Single Screw Pump

Get Price Quote

If low-pulsation of flowing of liquids is needed, then this Positive Displacement Single Screw Pump is the best. We are among the reliable names that offer world-class Positive Displacement Single Screw Pump at rates that will not pinch the client at all. Why Our Positive Displacement Single Screw Pump? Excellent capacity Hassle-free operations Can easily convey abrasive mediums

Two Spindle Screw Pump

10,000 - 200,000 Per Piece

A pair of specially profiled screw, machined integral from solid stock and well supported on antifriction bearings run in precision bored interchangeable casing liners. Each screw set has one right hand and one left hand screw engaging with a similar but opposite hand screw pair. A pair of hardened and profile ground timing gears synchronize the screws to maintain a small but positive clearance between the flanks thus ensuring no metal to metal contact. The pumps can therefore run dry for sometime without any damage. This unique feature enables to run the pump even dry and handle fluids that do not have enough lubricating value and also very low or high viscous products. Consequently, since there is no metal to metal contact; wear and tear is reduced to the minimum, ensuring extremely long service life. With two pairs of screws running in the same casing, the internal velocities are very small - consequently the NPSHR is practically the lowest even when the pumps run at motor speeds and while handling viscous products. Opposed screw pitches totally eliminate axial thrusts. Relatively small diameters of screws enables the pump to operate at high speeds directly coupled to prime movers - without the need for speed reducers even while handling high sealing’s always under suction pressure, thus making use of simple, inexpensive seals. The axial flow without turbulence, rotation, churning, chewing guarantees gentle handling of products. Noise and vibration or ---- levels are about the lowest. Positive clearance between running parts makes it easier to construct the pump in different materials safely, especially in stainless steel, without the fear of seizing. Thus a variety of fluids can easily be handled by selecting the right materials of construction. Typical Parameters Temperature: -30 to +350°C Viscosity: 1 cSt to 50,000 cSt or more Capacity: 20 to 500 m3/hr Pressure: Normal 16 bar/ 24bar, with special designs up to 50 bar Specialties: Partial heating/ complete heating/ cooling arrangements Sealing: Stuffing box/ mechanical seal with or without quenching/ heating/ cooling Mounting: Horizontal foot mount/ vertical pedestal Accessories: Relief valves, base frame, coupling, coupling guard, companion flanges, pressure gauges, electric motor/ diesel engines, variable speed drives and as per customer requirements. Typical Applications Loading / unloading of fuel oil and other products from: Railway wagon rakes, Truck tankers, Barges, Ships and Tankers. Bulk cargo handling. Lubrication, circulation and cooling. Process pumping of high viscous products, bitumen, molasses, soap and similar products. Long distance pipeline pumping of viscous products.

Dry Screw Vacuum Pumps

Get Price Quote

The dry screw pump design is based on the operating principle of screw but with twin screws to achieve the required compression. Two single-piece, parallel, twin screws contained in a pump body, compresses & transfers the gas by rotating twin screws. The pump body is cooled by water circulating through a jacket, cooling the compressed gas to discharge at low temperature. The temperature of the pump can be adjusted for process requirements by controlling the water flow rate and temperature. This will raise or lower the overall operating temperature of the gases being pumped. The compression ratio of the pump varies little over the operating pressure range, giving constant absorbed power. This enables the condition of the pump to be diagnosed by monitoring motor current.

Progressive Cavity Pumps

Get Price Quote

We deal in range of progressive cavity pumps that are built with rugged gear-type universal joint which is the effective solution to handle heavy radical thrust loads. This design ensures best performance with very minimal maintenance, low wear & tear rotating parts and longer life of pump. Unique fitment of pumping elements a. Precision machined rotor and elastomer stator design reduces slippage for higher efficiency and improved volumetric effeciency. B. Hard chrome plated rotors provide high abrasion resistance and longer service life. c. Wide variety of elastomers available for every applications with proven qualities sailent features of hydro prokav km 2000 progressive cavity pumps ⷠlow total cost of ownership ⷠpositive displacement ⷠnon-pulsating flow ⷠaccurate, repeatable flow ⷠhead independent of pump speed ⷠlow npsh requirement ⷠself-priming ⷠhigh suction lift upto 28 feet ⷠlow shear ⷠparticles upto 2.8 � in diameter ⷠreversible ⷠviscosities up to 1,000,000 cps ⷠsimple pin-type universal joint drive assembly for easy maintaince ⷠmodular design ⷠwide selection of materials of construction special designs available confirming to api 676.

Screw Pump

Get Price Quote

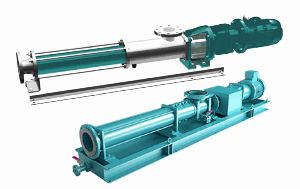

Progressive Cavity Screw Pumps

65,000 Per Set

1 Set(s) (MOQ)

We are offering progressive cavity screw pumps. Seal proof make progressive cavity screw pump this positive displacement screw pumps works very fast and provides excellent performance. These pumps are easy in operating and take repairs. These pumps are fabricated using advanced technology and highly cherished by the customers for their features. We manufacture and export positive displacement screw pumps to the customers in a vast range.this value progressive cavity pumps are of heavy duty construction and are designed to pump ‘tough – to – handle’ fluids with ease. These pumps are used in many areas of industry. The construction of these pumps is based on the modular concepts and incorporate next generation pumping elements (molded to metal) stator, solid shaft and double sealed cardan universal joints for improved performance and longer service life. These pumps are available in bare shaft and close coupled configuration. 6 and 8 stages in select sizes. A variety of material of construction, shaft sealing options are also available.

PC 12B Mini Condensate Drain Pump

Get Price Quote

PC – 12B Mini Condensate Drain Pump Low noise control Compact modern design High flow rate Built – in alarm circuit Suitable for all kinds of air conditioners Voltage : 100 ~ 230V, 50/60 Hz Suction lift : Max.2m(6.5ft) Discharge head : Max.10m (26ft) Flow rate : Max.12L/H (3.2GPH) Tank capacity : 35ml

Screw Pump

Get Price Quote

Progressing Cavity Pumps are rotary positive displacement pumps. The main component, a metal rotor, which is in the shape of a single external helix, rotates around its on axis in the direction of rotation (say clockwise); while the axis of the rotor, revolves in the opposite direction (say anticlockwise) around the axis of the stator. The stator is made of and elastomeric bonded to end alloy steel tube. The stator itself is in the shape of an internal double helix. The rotor is contained within the stator and forms a continuous seal along the length of the stator. The above movement produces cavities at reduced pressures which move axially from the inlet to the outlet conveying the fluid at fixed flow rate proportional to the rotational speed. Features : > Abrasion resistant chrome plated rotor > Stator elastomers to suit specific requirement > Wide range of material of construction > Hardened bush pin type universal joint sealed and grease lubricated > Heat treated, hard chrome plated drive shaft Specification : UBH Series: Standard S SeriesCapacity: upto 250 m3/hr Head 12 kg/cm2Capacity: upto 72 m3/hr Head 24 kg/cm2UBH AG Series: Sugar Type S SeriesCapacity: upto 250 m3/hr Head 12 kg/cm2Capacity: upto 72 m3/hr Head 24 kg/cm2UBH VT Series: Vertical Type S SeriesCapacity: upto 72 m3/hr Head 24 kg/cm2

TRIPLE SCREW PUMPS / THREE SCREW PUMPS

Get Price Quote

GENERAL INFORMATION (TH 1X PUMPS) WORKING PRINCIPLE Triple Screw Pumps are positive displacement pumps of very simple design They consist of three rotating parts only the rotors" which turn in their precisely machined housing bores. The rotors are of double start screws, continuously meshing to form delivery chambers, which move constant y from the suction to the pressure / discharge side. Constant volume oi the chambers and the uniformity of the movement allow an even flow The pumps remain therefore near silent in operation and almost free of pulsation, even at high speed The Principle of screw pump and its accurate profiles warrant high suction power. Axial loads on the rotor are compensates by adequate design of the bearing part. All the radial loads are self-compensated. APPLICATION Triple Screw Pumps, type TH are used for die transfer of fluids with lubricating properties, as well as for generating pressure in hydraulic units or overcoming pressure in the hydraulic circuits. Main Industrial uses are in: Power Hydraulics Power Generation Lube industries Machine Tools Windmill Oil & Gas Compressor Lubrication Presses Marine Filtration TYPICAL LIQUIDS All kind of Bunker Oil, Engine oil, Furnace oil, Heating oil, Hydraulic Oils, High Viscosity Lubrication Oil, Mineral oil, Synthetic Oil, 0il Water Emulsions and Fuel 0ils, Diesel Oil, LSHS, LDO. MATERIAL OF CONSTRUCTION Pump Housing : Carbon Steel, Cast Iron, Stainless Steel Liner : Alluminium Alloy / Cast Iron / Copper Rotors : Main Screw : Alloy Steel, Hardened Steel and Surface Treated Steel Idler Screw : Hardened Steel, Surface Treated Steel Shaft Sealing : Mechanical Seal / Lip Seal with Elastomers in Viton, EPDM & Nitrile / Gland Pack/Graphoil Rings Mounting Frames : Fabricated Steel Relief Valve Parts : In Steel & Cast Iron EXECUTION The pumps here described may be incorporated in various housings and supplied as Foot, Flange or Pedestal Pumps. We also supply cast or welded housings to your specifications. To adapt the pumps to various applications, they can be fitted with the following seal variations: Radial shaft seals Gland packings (stuffing box) Mechanical seals PRESSURES Upto 120 bar are admissible. INSTALLATION Screw-Pumps work perfectly in any position, provided suction and pressure lines are arranged in a way that prevents emptying of the pump when at a standstill. DIRECTION OF ROTATION Clockwise from the Shaft End of the Pump (Standard) Anticlockwise from the Shaft End of the Pump (On Request / Non Standard) DRIVE In general the pumps are connected with a flexible coupling to a foot or flange mounted motor. Radial loads onto the shaft end are not permissible, unless when absorbed by an additional external bearing, e.g. in case of pump drive by belts or gears. SPEED OF ROTATION Shaft Speed Ranging from 500-3600 RPM Do not exceed 1500 RPM when pumping residual fuels, crude oil due to the presence of abrasives and contaminants. VISCOSITY Normal range 21,5 to 385 cSt. Depending on type, pressure, speed and suction conditions, fluids with viscosities ranging from 6 to 3800 cSt may be pumped. Regarding viscosities outside the normal range. Please consult us! TEMPERATURE RANGE When fitted with standard radial shaft seals, up to 90 Deg C. Depending on operating conditions, temperatures as high as 180 deg C are permissible. Please ask us! Cooling Jacket & Heating Jacket for the pump body & covers can be provided for easing the cold start of the pump and for continuously pumping liquids at high temperature. SUCTION LIFT OR INLET PRESSURE For speed between 1000 and 1700 r.p.m and viscosities below 385 cSt you may reckon with an absolute manometric suction lift of maximum 0,5 bar. For other speeds or viscosities. Please contact us! The inlet pressure should not exceed +0,5 bar, when radial shaft seals are used. For higher inlet pressures we offer gland packings or mechanical seals. If the suction lift condition exceeds the pump capability, cavitation will occur resulting in noise and possible pump damage. SUCTION AND PRESSURE LINES The cross section of the suction line should be such that fluid velocity nowhere exceeds 1 m/sec. In the pressure line velocity should not exceed 5 m/sec. PRESSURE RELIEF VALVE All housings described here may be obtained with or without pressure relief valve, which we supply at your option as by-pass valve, connected to the suction chamber, or as return valve, conducting the fluid by a separate connection to the tank. When a larger quantity should have to pass through the valve for more than 10 seconds, a return valve has to be fitted, to avoid an undue rise in temperature. FILTRATION The pumps must be protected against solid particles in the fluid by suitable suction filters. The mesh width should be 0.1 mm and care has to be taken that even with a contaminated filter the admissible suction lift capability is not exceeded.

Feed Pumps

Get Price Quote

Double Diagraph PumpThe low pressure diaphragm pumps of the Zip range are first choice for high quality pumps. This pneumatically operated double diaghragm pumps work with extremely low pulsation. The pumps are equipped with the low icing "Runner" air motor, which is characterised by low consumption with maximum reliability and performance. Product Benifits: Low pulsation thanks to quick operating anti-stall air pilot valve High flow rate Suitable for many different materials Long life diaphagms Low noise level (integrated silencer) Compact design High suction capacity Wide range of available models

Screw Pumps

Get Price Quote

We are offering screw pumps. Product range: •progressive cavity screw pumps •two screw pump •three screw pump.

Screw Pump

Get Price Quote

Feed Pumps

Get Price Quote

Feed pumps in vane-type construction with constant supply volume. Typical applications: Filter circuits Cooling circuits Lubrication technology Pump transfer units Please select:

Hygienic Centrifugal Pumps

Get Price Quote

Sanitary pump Self Priming pumps Rotary Lobe Pumps Hygienic centrifugal pumps

Three Screw Pump

Get Price Quote

Typical Applications Machinery lubrication,hydraulic elevators,fuel oil transport and burner service,powering hydraulic machinery,polymer pumping,in refinery process for high temperature viscous products such as asphalt,vacuum fower bottoms and residualfuel oils.

Twin Screw Pump

12,000 Per Piece

Twin Screw Pump

Get Price Quote

1 Piece (MOQ)

We are offering twin screw pump. • absolutely no metal-to-metal contact between the moving screws as a small positive clearance is maintained between them. This ensures the pump very long operational service, resulting in no wear and tear of pump parts. • pump capable of running dry • screws are mounted on the timing gears and the speed of both the screws are therefore synchronized resulting in pulsation free, turbulent free flow • flow of the liquid is always in the straight path • sealing is situated at the suction pressure • pump requires very low npsh (net positive suction head) • the rotation of screws is perfectly balanced resulting in no vibration and negligible noise.

Viscous Mono Screw Pump

Get Price Quote

1 Piece(s) (MOQ)

We are a renowned manufacturer and wholesale supplier of Viscous Mono Screw Pump from Mumbai in India. Also known as a progressive cavity pump, the viscous mono screw pump we offer is precision engineered to match international standards. They are pressure tested to ensure their durability and performance. We use antifriction bearings and carbon steel-spur or double helical spurs to ensure optimal performance and efficiency in our Viscous Mono Screw Pumps.

Syno Pumps

Get Price Quote

Manufacturing & supplying of rubber products, gear pumps, molasses pumps, progressive cavity pumps, screw pumps, industrial pumps.

Rotary screw vacuum pumps

250,000 Per Piece

Two Spindle Screw Pump

Get Price Quote

Delta Twin Screw pumps work on unique principle that makes it the only choice for certain applications. No other design of Positive Displacement Rotary pumps offer so much versatility in the operating parameters with guaranteed total reliability and maintenance-free service. Delta Group have earned a reputation of providing the most reliable Positive Displacement Pumps for practically any given application since 1968 due to the widest choice of designs available and excellent knowledge of application engineering. Continuous Research and Development together with modernization with CNC machines and testing facilities has enabled us to accept challenging jobs. Several of Delta pumps in operation since decades to the total satisfaction of the users in core industries throughout the country and abroad are a silent testimony.Working PrincipleA pair of specially profiled screw, machined integral from solid stock and well supported on antifriction bearings run in precision bored interchangeable casing liners. Each screw set has one right hand and one left hand screw engaging with a similar but opposite hand screw pair. A pair of hardened and profile ground timing gears synchronize the screws to maintain a small but positive clearance between the flanks thus ensuring no metal to metal contact. The pumps can therefore run dry for sometime without any damage. This unique feature enables to run the pump even dry and handle fluids that do not have enough lubricating value and also very low or high viscous products. Consequently, since there is no metal to metal contact; wear and tear is reduced to the minimum, ensuring extremely long service life. With two pairs of screws running in the same casing, the internal velocities are very small - consequently the NPSHR is practically the lowest even when the pumps run at motor speeds and while handling viscous products. Opposed screw pitches totally eliminate axial thrusts. Relatively small diameters of screws enables the pump to operate at high speeds directly coupled to prime movers - without the need for speed reducers even while handling high sealing’s always under suction pressure, thus making use of simple, inexpensive seals. The axial flow without turbulence, rotation, churning, chewing guarantees gentle handling of products. Noise and vibration or ---- levels are about the lowest. Positive clearance between running parts makes it easier to construct the pump in different materials safely, especially in stainless steel, without the fear of seizing. Thus a variety of fluids can easily be handled by selecting the right materials of construction.Typical ParametersTemperature: -30 to +350°CViscosity: 1 cSt to 50,000 cSt or moreCapacity: 20 to 500 m3/hr Pressure: Normal 16 bar/ 24bar, with special designs upto 50 barSpecialties: Partial heating/ complete heating/ cooling arrangementsSealing: Stuffing box/ mechanical seal with or without quenching/ heating/ coolingMounting: Horizontal foot mount/ vertical pedestalAccessories: Relief valves, base frame, coupling, coupling guard, companion flanges, pressure gauges, electric motor/ diesel engines, variable speed drives and as per customer requirements.Salient FeaturesPositive clearance between rotors Insensitive to varying viscositiesNo metal to metal contact between rotors Long maintenance free serviceDry running capability Lowest NPSHRNegligible wear over years Shaft sealing at suction pressuresAxial smooth steady flow Axial thrusts completely eliminatedHigh speed running Interchangeable linerPulsation free output Adaptability of various MOCNegligible vibrations Typical ApplicationsLoading / unloading of fuel oil and other products from: Railway wagon rakes, Truck tankers, Barges, Ships and Tankers.Bulk cargo handling.Lubrication, circulation and cooling.Process pumping of high viscous products, bitumen, molasses, soap and similar products.Long distance pipeline pumping of viscous products. Typical Liquid ListAdditives ParaffinBase oils Petroleum productsBitumen PolyesterFuel oils - all grades ResiduesLubricating oils - all grades SoapLyes Vegetable oilsMolasses Major IndustriesPetroleum refineries, Terminals, Depots, Oil blending stations, Thermal power plants, Steel plants, Fertilizer industries, Petrochemical plants, Carbon black, Sugar, Paper and Pulp, Marine.

Tushaco Screw Pumps

80,000 - 87,000 Per Piece

HELICAL ROTOR PUMP

Get Price Quote

Jung Process Systems pumps

Get Price Quote

Jung Process Systems is a German manufacturer of the HYGHSPIN series - twin screw pumps known for their hygienic, high performance and gentle treatment of aqueous or viscous media. These pumps are specially designed for the food & beverage, dairy, confectionary, cosmetics, and pharmaceutical industries. We have taken up sole distributorship in India in 2015 General Features Pumps aqueous or highly viscous media. High suction performance. Product and CIP can be handled with only one pump. Pumping of fibrous media and products containing pieces. Abrasion-free gentle treatment: no contact between feeding elements. Supply rates up to 200 m3/hr. EHEDG and GOST-R certified. Simple assembly and disassembly.

Hygienic Steel Pumps

Get Price Quote

hygienic pumps

Get Price Quote

Dry screw vacuum pump

Get Price Quote

Erpl india is a leading manufacturer of dry screw vacuum pumps in mumbai and offers a wide range of reliable, long-life dry screw vacuum pumps.

Positive Displacement Pump

68,000 Per Piece