Vibro Sifter

Get Price Quote

This machine is used for various applications like Sieving, Grading and Sizing of dry Powders and Granules in Pharmaceutical, Chemical, Food, Dye and Cosmetic industries.Machine is designed to Screen dry products through any mesh size as per particle size Also available in double / triple / four decks for multiple grading sizes in the same batch in the same processThe structure of the machine has been designed in order to achieve multiple plane vibration by suitable assembly of the specially designed Vibratory motor having eccentric weight at the top and bottom ends of the motor shaft. The motor is mounted vertically at the centre of the screening assembly, on a circular base by means of springs which allow the Unit to vibrate freely. The springs absorb the vibrations and prevent them to be transmitted on the floor.

Vibro Sifter Machine

200,000 - 500,000 Per Piece

1 Piece (MOQ)

Vibro sifters are circular gyratory screens used to separate mass composition of solids, liquid form solid and for gradation of materials as per particle sizes. Vibration is generated in three different planes along the vertical axis by means of a specially designed vibratory motor having off centered weights at the top and bottom end of the motor shaft. The angle of lead of the lower weight to the up per weight provides variable screening pattern & output. FEATURES -: Available in standard and GMP models with contact parts in stainless steel 304 or 316 quality. Portable unit with higher output. Double and triple deck unit with different screens can be provided easy to dismantle for cleaning screens. Noiseless, maintenance free unit. Model Available – 12” , 20“, 30“, 48“, 60”

Best Deals from Separating Machines

Moisture Separator

Get Price Quote

5 Piece (MOQ)

Vibro Sifter Springs

250 Per Piece

100 Piece (MOQ)

Vibro Sifter

115,000 - 375,000 Per Piece

1 Piece (MOQ)

Description: Design as per stringent cGMP requirements Powerful vibration by special vibro motor Easy movable and cleaning All contact parts SS 316 Noiseless operation Available models 12", 20", 30", 48", 60" & 72

Moisture Separator

12,999 - 9,999 Per Piece

1 Piece (MOQ)

Vibro Sifter Machine

Get Price Quote

3 Piece (MOQ)

VIBROSIFTER (AVAILABLE CAP: 12”,20”,30”,34”,36”,48”& 60”) Ideal for gradation and separation of dry powder, granules and semi solids/ liquids. Dust free arrangement, lead free sieves. SALIENT FEATURES Manufactured as per cGMP norms. Design permits easy washing and cleaning. Flexible discharge height. Reduced binding and clogging of the sieves. Superb aesthetic look Minimum break-down & maintenance cost. Less power consumption & running cost.

Vibratory Gyro Screen

50,000 - 300,000 Per Piece

1 Piece (MOQ)

Applications :Pharmaceutical Industry, Paint Industry, Ceramic Industry, Food Industry, Paper Industry, Rubber Industry, Abrasive Industry, Breivery Industry, Chemical Industry, Plastic Industry, etc. Advantages :Over conventional separators are : Efficient separation High output Low power consumption Less space requirement & Maximum flexibility Low Maintenance Longer screen life No transmitted vibrations

Air Oil Separators

Get Price Quote

1 Piece (MOQ)

Company offers genuine screw compressor air oil seperators custmized filter cartridges and seperators mnfrs as per drawing or sample in very reasonable price

Air Oil Separators

1,375 Per Litre

Company offers genuine screw compressor air oil seperators custmized filter cartridges and seperators mnfrs as per drawing or sample in very reasonable price

Vibro Sifter

50,000 - 190,000 Per Piece

1 Piece(s) (MOQ)

Vibro Sifter Machine

1 - 4 Per Bag

1 Piece (MOQ)

Vibro Sifter

Get Price Quote

Vibro Sifter find application in Separation of solids from solids/ liquid & grading of materials as per product mesh size. The range of Vibro Sifters that we offer are of high pharmaceutical finish made to cGMP Constriction. MERITS Sizes available in 12”, 20", 30", 36", & 48" High degree of pharmaceutical finish. Double Decker arrangement can be provided. Easy dismantling and cleaning. MOC SS 304 / 316 / 316L Modular Design Of Decks With Easily Fitted Clamps Dust Free Arrangement, Lead Free Sieves available Output 50 To 200 Kgs/Hr Depend Upon Characteristic Of Material Silicon Moulded Sieve available cGMP Construction with documentation

Hydro Machine & Oil Separator

Get Price Quote

Remove Extra Oil/ Water & Moisture From Namkeen, Bundi, Khara, All Types Chips & Many More, No Need To Foundation.

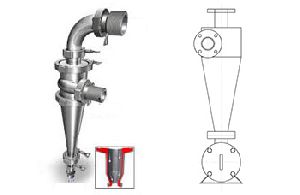

Cyclone Separator

Get Price Quote

Vibro Sifter Machine

70,000 Per Per Machine

1 Piece (MOQ)

Cyclone Separators

Get Price Quote

We offer wide range of Cyclone Separators This is a device to separate solids (in powder or granular form) from air/gases. When the material is moving as in pneumatic conveying, the solids are separated. In this device, air is made to flow at cyclonic speed and made to rotate in a cylindrical vessel of suitable design. When the solid material attains high speed, it picks up centrifugal force and choose to hold tightly to outer surface while air retains high speed it gets due to its velocity factor. Suddenly in the center, air outlet is provided for air to go out while due to centrifugal force the solid material is not able to change direction but goes downwards and gets separated. This device is capable of offering separation efficiency up to 90 %, of course depending upon design, material, bulk density etc. There is one collecting hopper where material gets collected. Smaller the diameter better is the efficiency.

Vibro shifter

Get Price Quote

Vibro Shifter is a portable and versatile screening machine that is used for screening a wide range of solids or liquids that are utilized in different industries like food, pharmaceuticals, chemical, paint & mineral industries. Vibro Shifter is operated by a vibratory motor with unbalanced weights. The frequency of the vibrations can also be controlled by the operator. Parts of the Vibro Shifter can be easily removed or replaced for maintenance purpose. Further, Vibro Shifter is provided with wheels and towing handle for easy mobility. Construction Features Circular, floor mounted. Modular design allows quick and easy change over of decks. Optional dust cover to prevent dusting of surrounding. Range : 24" Diameter to 72" diameter. Multideck construction (Maximum upto seven decks). Decks made out of MS Powder coated / SS 304 / SS 316. Screen Cloth : SS 304 / SS 316 / Nylon. Uniformly tensioned screens ensure maximum screening efficiency. Variable output by simple adjustment of unbalanced weights mounted on motor shaft. No transmission of vibrations to floor as deck assembly is mounted on base frame by rugged springs. Can be adapted to meet factory layout needs as no foundation is required. Operation : The material to be screened is fed into the top deck of the vibrating screen. The material passes through the screen wire mesh. Oversize particles remain on the top of the screen cloth. These particles move towards the periphery of the screen due to the vibrations imparted by unbalanced vibrating motor and flow out through the discharge spouts. The material which has passed through the screen cloth falls on the top of bottom deck. This material also moves towards periphery and flows out through the discharge spout. The material movement towards periphery can be controlled precisely by adjusting the angle between the top eccentric weight and bottom eccentric weight as the adjustment of angle leads to different flow patterns.

Vibro Sifter

Get Price Quote

We are engaged in manufacturing of Vibro sifter machines & Vibro sifter clamps in various sizes & MOC according to the clients requirement. The basic application of Vibro sifter machine is for separation purpose of dry & Solid liquid which can used accordingly as per clients requirement for various purpose for separation or clarification of liquids. Vibro sifter are used in various industries such as Process Industries, Food Industries, Chemical Industries etc. The use of Vibro sifter extensively depends on client needs. Product Specification : MVS24 : Size - 24’’ Screen - SS304 & SS316(Size according to client requirement) Capacity Charging Height Discharging Height Motor - Electric Vibratory motor. Vibro Clamp - SS304 & SS316(According to client requirement) Gasket - Teflon/ Food Grade Neoprene Net Weight Machine Dimension Power Supply MOC - SS304 or SS316.(According to clients requirement). MVS30 : Size - 30’’ Screen - SS304 & SS316(Size according to client requirement) Capacity Charging Height Discharging Height Motor - Electric Vibratory motor. Vibro Clamp - SS304 & SS316(According to client requirement) Gasket - Teflon/ Food Grade Neoprene Net Weight Machine Dimension Power Supply MOC - SS304 or SS316.(According to clients requirement). MVS48 : Size - 48’’ Screen - SS304 & SS316(Size according to client requirement) Capacity Charging Height Discharging Height Motor - Electric Vibratory motor. Vibro Clamp - SS304 & SS316(According to client requirement) Gasket - Teflon/ Food Grade Neoprene Net Weight Machine Dimension Power Supply MOC - SS304 or SS316.(According to clients requirement). MVS60 : Size - 60’’ Screen - SS304 & SS316(According to client requirement) Capacity Charging Height Discharging Height Motor - Electric Vibratory motor. Vibro Clamp - SS304 & SS316(According to client requirement) Gasket - Teflon/ Food Grade Neoprene Net Weight Machine Dimension Power Supply MOC - SS304 or SS316.(According to clients requirement).

Vibro Sifter

Get Price Quote

We are offering vibro sifter. Vibro sifter is widely used for sieving, sifting, grading of powders & granules. It is ideal for obtaining uniformly sized particles in a batch. It has variety of applications in food, pharma-chem industries etc.