Heavy Duty Shearing Machine Manufacturer from Maharashtra

100,000 - 500,000 Per piece

1 Piece (MOQ)

Cnc Gear Shaping Machines

Get Price Quote

We are counted amongst the reliable Exporters and Traders of state of the art CNC Gear Shaping Machines. We offer CNC Gear Shaping Machines majorly in below mentioned models : SO 400 CNC : It is a 6 axes CNC controlled high speed gear shaping machine. It is a fully automatic machine with electronic guide. Helical guide is not required for cutting helical gears. SO 800 CNC : It is a 5 axes CNC controlled large gear shaping machine, equipped with hydrostatic guideways & hydrostatic bearings on its cutter head.

Best Deals from Shearing Machines

Shearing Machines

Get Price Quote

1 Piece(s) (MOQ)

Hand Metal Sheet Shearing Machine

Get Price Quote

This is Extra Heavy Duty 2500 X 1.0 Mm in Mild Steel Capacity Hand Operated Shearing Machine. this is Well Constructed and Ideal Basic Machine for Various Shear Able Materials like M.s., S.s., Aluminium, Mica, Copper, Plastic, Gaskets, Fiber Etc these Hand Operated Shearing Machines are Designed and Constructed to Provide High Degree of Stability Ensuring Precise Burr Free and Accurate Cutting. Cutting Process is Cam Actuated, Very Simple, Safe and Effortless. the Machine is Equipped with C.i. Slides Wherever Required. Spring Loaded Hold Down Devices are also Provided for Firm Clamping of Sheets While Cutting to Ensure Parallel Cut. both Lower and Upper Blades of Machines are Proper Alloy Steel, Properly Hardened and Ground, Having Four Cutting Edges the Machine is Available in Various Sizes from 1000mm upto 2500mm Width and Having Maximum Cutting Capacity in Ms of upto 1.6mm.

Metal perforating machine

Get Price Quote

The sheet is fed to the machine by means of a Roller System Mechanism. The die is preloaded on the machine. On feeding the sheet, the upper section of the machine starts stroking. The sheet is perforated as per the die and is advanced by the amount of the perforated pitch set on the machine, with the next stroke of the slide. This cycle of feeding and perforating continues automatically.

Food Operated Treadle Shearing Machine

Get Price Quote

Gear Shaper

Get Price Quote

We are offering gear shaper. Maximum module : 06 max.dia of gear wheel : 500 mm with ext. Teeth max.dia of gear wheel : 450 mm with ext. Teeth face width : 90 mm table diameter : 508 mm max.distt. Ram : 200 mm

mechanical shear

Get Price Quote

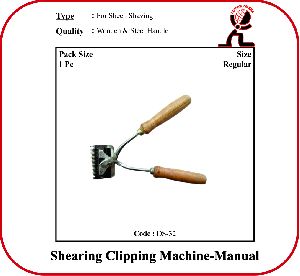

Shearing Clipping Machine - Manual

1,800 Per PIECE

1 Piece (MOQ)

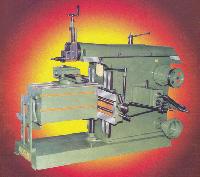

Undercrank Guillotine Shearing machine.

Get Price Quote

This undercrank guillotine shearing is available in various sizes from 1250 x 2mm to 3125 x 3mm in MS cutting capacity. This is a power operated under crank type guillotine shearing machine featuring all steel body solid construction for accuracy and dependability. The crankshaft runs in gun metal bushes and fly wheel shaft runs in ball bearings for smooth trouble free operation. This guillotine shearing machine is supplied complete with four edge HCHCr steel shearing blades, suitable power three phase AC electric motor, hand operated back gauge, front gauge, side gauge, belts, guards and shot lubricator. This power shearing machine is available in various sizes from 1250 x 2mm to 3125 x 3mm cutting capacity in mild steel with Tensile.Strength of 42 kgsq. cms. Kindly ask for more details.

Hydraulic Shear Cutting Machine

85,000 Per Piece

1 Piece (MOQ)

Treadle Shearing Machine

Get Price Quote

FOOT / TREADLE SHEARING MACHINE

Shearing Machines

Get Price Quote

01 Piece(s) (MOQ)

Offers shearing machines. Cold shear for tmt round bars for capacity to cut from 8mm to 40mm, mechanically operated clutch type.

Heavy Duty Shearing Machine

Get Price Quote

We have carved a niche in this industry for offering Geared Heavy Duty Shearing Machine to the patrons. These machine is designed for manual cutting of hard sheet metals. It can cut strips, irregular shapes or slit sheet of steel and other materials. It has improved functional facilities and its convenient in operation. These are checked over the grounds of quality stages to ensure the delivery of defect-free range to the clients end.

Shearing Machines

700,000 Per Piece

1 Piece (MOQ)

Paper Shearing Machine

Get Price Quote

Hydraulic Shearing Machine

Get Price Quote

Hydraulic Shearing Machine, which we provide, is acclaimed for hassle-free performance, low maintenance cost, robust construction and ease-of-operations. We offer these Hydraulic Shearing Machines at the market leading rates to the clients. We are among the trusted Manufacturers, Suppliers and Exporters of Hydraulic Shearing Machine. Availability : We have Hydraulic Shearing Machines that perform shearing from 4 mm to 25 mm

Sheet Shearing Machine

Get Price Quote

Our experts ensure that payments are made on time and for that, we have online payment processing system to evade security issues. We have well maintained payment logs available for the convenience of our customers. Located in Thane(India), we ensure safe and secure deliveries, throughout the country, within the agreed time frame.

Shearing Machine for sheet

Get Price Quote

1 Piece(s) (MOQ)

This machine is required for cutting sized body blank & top bottom blanks from a sheet or a coil. The basic structure is steel fabricated that gives it an extra strength and rigidity.

Shearing Machines

50,000 - 60,000 Per piece

1 1 (MOQ)

2ft size Ms body 1hp gear motor 55 rpm Semi automatic machine

Gear Shaper Machine

Get Price Quote

AP-E gear shaping machine

Get Price Quote

AP-E is the medium-high speed model dedicated to catering rolls. Four stations turret type. Production: up to 100-120 rollsh of 150 mt alu foil 60-70 rollsh of 300 mt cling film

guillotine shears

Get Price Quote

Customers can provide their specifications to us in regards to the packaging of the products as we serve customized packaging requirements. We ensure damage-free products at customer's end. We are a quality-conscious firm and for ensuring high quality of the products, we dedicatedly work in tune with the defined industry standards.

treadle shearing machines

Get Price Quote

We are a credible name that is involved in the manufacturing and exporting of best quality Treadle Shearing machine. Known for cutting the border of the printed sheets, it is widely acknowledged in the market. Owing to its sturdy construction and power coated finish, the qualitative range of treadle shearing machines offered by us is highly demanded in the market. Features: DurableEasy maintenanceAccurate dimension

Overcrank Mechanical Motorised Shearing Machine

Get Price Quote

Shearing Machines have been designed and developed through structural analysis technique for continuous production, accuracy and repeatability having the following main features: Frame : Rigid steel frame of shears are optimally designed to avoid week sections at load support and is of interlocked design.The ram is guided throughout its length by accurate machined guideways ensuring proper clearance and clean cut. Hold-down system : Spring loaded mechanical Hold down pads hold the sheet securely, to avoid slipping and bowing resulting in clean square cuts. Holddown units are provided with oversize pads to avoid impressions on sheet metal on request. Hold-down system : Hydraulic Hold down pads are accurate calm operated pump. Hydraulic Hold down pads hold the sheet securely, to avoid slipping and bowing resulting in clean square cut. Hold down units are provided with oversize pads to avoid impressions on sheet metal on request at extra cost. Knives : Shears are provided with high quality single segment (HcHcr) Knives for longer tool elite. Ease in assembling of knife reduces down-time. The knife blades are four edged. Lubrication : All bearing parts and guide surfaces are lubricated through hand-operated lubrication system. Mechanical backguage : This is standard equipment provided on all shears. Scale on backguage gives instantaneous reading of distance between shear and backguage. Thus avoiding errors and maintenance in electronic equipment. Finger guard : Fitted in front of hold-down for operator protection without abstructing viewing.

Cnc Gear Shaping Machines

Get Price Quote

CNC Gear Shaping Machines Reliable and Proven Design High Speed Single and Multi-stroke Helix-angle setting Ease of Operation Option for Auto-loading unloading

Hydraulic Shearing Machine

Get Price Quote

For efficient cutting of both metallic and non-metallic materials, we offer precision engineered Hydraulic Shearing Machine. Our Hydraulic Shearing Machine is suitable for cutting materials of different specifications like large sheets, bars and plates. Smooth and precise cutting is guaranteed with our high-end Hydraulic Shearing Machine. Long service life with safe and easy operation of our Hydraulic Shearing Machine is highly appreciated. Better stability, low noise in operation, vibration free work, reduced material wastage, etc. are some of the benefits of using our Hydraulic Shearing Machine. Application Areas Automobile IndustryPrinting PurposeFood Processing IndustryEngineering sectorElectronic IndustryPlastic IndustryWood workingElectrical IndustryConstruction Industry Technical Specifications Range : 6mm to 25mmLengths : 1250mm to 6000mm Quality Blades Shears up to 4mm Capacity equipped with high carbon, high chrome blades, All models, 16mm Capacity and above, are furnished with "shock resistant" steel blades. Silent Features Reliable in prize & compact in designingBetter cutting accuracy in thin sheets at lower rake angleHigher cutting capacity at maximum rake angleLow cutting angle produces straight cut with minimum distortionCapable of shearing a wide range of materialsModern design ensures trouble free operationHigh speed, accuracy & reliabilityEnergy efficientStandard installation on demandUser-friendly arrangementsLower vibration & noise with smooth operation gives higher efficiency of operator & machine Technical Specifications Model Cutting Length (in mm) Shearing CapacityThickness in mm Variable Rake Angle in degree Strokes pe minute App No. Of Hold down Back Guage Power in H.P Holding Force in Kg. M.S S.SMHV615 1525 6 4 0.5-3 10-20 7 750 7.5 6500MHV620 2030 6 4 0.5-3 12-24 8 750 10 6500MHV625 2540 6 4 0.5-3 08-24 11 750 10 8500MHV630 3125 6 4 0.5-3 10-20 13 750 12.5 10800MHV640 4000 6 4 0.5-3 09-18 18 750 15 13600MHV815 1525 8 6 0.5-3 08-16 7 750 10 10500MHV820 2030 8 6 0.5-3 10-20 9 750 12.5 12000MHV825 2540 8 6 0.5-3 09-18 11 750 15 16500MHV830 3125 8 6 0.5-3 08-16 13 750 20 18500MHV840 4000 8 6 0.5-3 08-16 18 750 25 20000MHV850 5000 8 6 0.5-3 06-12 22 750 30 23000MHV863 6300 8 6 0.5-3 02-03 26 750 40 25000MHV1015 1525 10 8 0.5-3 06-12 9 750 12.5 10500MHV1020 2030 10 8 0.5-3 10-16 11 750 15 13000MHV1025 2540 10 8 0.5-3 08-14 13 750 20 17500MHV1030 3125 10 8 0.5-3 05-11 15 750 20 20000MHV1040 4000 10 8 0.5-3 05-11 20 750 25 25000MHV1325 2540 13 10 0.5-3 07-15 13 750 25 16000MHV1330 3125 13 10 0.5-3 05-11 15 750 25 20000MHV1340 4000 13 10 0.5-3 05-10 20 750 30 25000MHV1625 2540 16 13 0.5-3 06-12 13 750 30 25000MHV1630 3125 16 13 0.5-3 05-10 15 750 30 20000MHV1640 4000 16 13 0.5-3 04-09 20 750 40 25000

Treadle Shearing Machine

Get Price Quote

Treadle guillotine shearing machine are indispensable in sheet metal industries as they lead amongst all on account of versatile design, rigid construction, rigorous tests for the capacities and appearance. Tredle shears are specially designed for rapid and continuous cutting of steel sheets of varied widths and trimming them in unlimited lengths. Features: *High tensile springs for quick return of treadle. *4 Cutting edged hardened & ground quality blades. *Rigid and streamlined construction. *Spring loaded sheet holding device. *All steel fabricated construction body. In every treadle shearing machine, the bed and top beam have full adjustments for correct setting and easy removal of blades for accurate cutting and for regrinding. The spring loaded pressure pad holds the The spring loaded pressure pad holds the perfect parallalism of cutting on either side. The adjustable front and back guages with running Tee slots facilitate adjustment of various widths of the cuts and avoid any kind of twistings, turning of sheets while cutting. Square guide on the side of the table facilitates square cuts. The cutting edge blades avoid frequent grinding & adjustment and also very easy to grind to the rectangular shape. These blades can be used with slight change in cutting angle to ribs, plastics, card board, rubber, mica etc., without any sign of squeezing or crushing.

Under Crank Shearing Machine

Get Price Quote

The offered by Sanket Enterprises Under Crank Shearing Machine is manufactured by making use of excellent quality steel alloy sheets of uniform thickness for its frame structure and high grade components for its efficient functioning.

Shaping Machine

Get Price Quote

We are offering shaping machine.