Metal CNC Engraving Machine

500,000 - 550,000 Per Set

01 Set (MOQ)

As a trusted name, we make use of only premium packaging material to pack the products in order to ensure their complete safety during transit. Moreover, our packaging experts strictly check the same. Our products are tested on various parameters during the production process to ensure their adherence to the industrial quality standards. Features : Advanced mechanishm Low maintenance High productivity

Laser Metal Cutting Machine

Get Price Quote

Best Deals from Sheet Metal Machinery

Precious Metal Gold Refining Machine

Get Price Quote

1 piece (MOQ)

Double Shaft Metal Shredder Machine

300,000 - 500,000 Per piece

1 piece (MOQ)

SHREDALL is the largest manufacturer of high-quality Double Shaft Metal Shredder Machines in India. With our unbeatable prices and industry-leading warranties, you can trust that you're getting the best value for your money. Our Double Shaft Metal Shredder Machines are engineered to handle even the toughest materials with ease. Featuring robust construction and powerful motors, these shredders can effortlessly break down a wide range of metals, including steel, aluminum, and copper. The Working of Double Shaft Metal Shredder The Double Shaft Metal Shredder Machine by SHREDALL simplifies metal recycling. Feed metal scraps into the shredder where dual rotating blades tear them apart, creating uniform particles. Safety features ensure operator protection, while regular maintenance keeps the machine running smoothly. Efficient and reliable, it's an essential tool for sustainable metal waste management. Shredding Material Streamlining waste management, reducing volume, and promoting recycling for sustainability. Shredding Machine Type The Shredder Machine is a double-shaft cross-cut type, which means it can shred waste materials into small, manageable pieces for further processing. Usage/Application Metal shredders play a critical role in the recycling and processing of metal materials across various industries. They are utilized in metal fabrication facilities to manage scrap metal generated during production processes. Recycling plants employ metal shredders to process discarded metal products, such as old cars, appliances, and structural components, into smaller, more manageable pieces for melting and reprocessing. Capacity With a shredder from 500 kgs/hr to 1000 kgs/hr, the machine is available for small, medium to large-scale operations. Automation Grade The Shredder Machine is fully automatic, which makes it easy to operate. Motor Power The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance. Country of Origin Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess. High Performance and Easy Installation When it comes to metal shredding, trust the experts at SHREDALL to deliver the high-performance, cost-effective solution your business deserves. Contact us today to learn more about our Double Shaft Metal Shredder Machines and how they can transform your waste management operations. Product Description What sets SHREDALL apart is our commitment to innovation and customer satisfaction. We continuously improve our designs to ensure maximum efficiency and durability, giving you a machine that will serve your business for years to come. And with our extensive nationwide network, you can count on reliable after-sales support whenever you need it. Contact Us We are here to assist you. Feel free to contact us: Email: info@shredall.in +91 9820020754 Conclusion SHREDALL Double Shaft Metal Shredder Machine offers a powerful solution for efficient metal recycling. With its robust design, cutting-edge technology, and user-friendly interface, it ensures high-performance shredding while prioritizing ease of use. From its durable construction to its advanced safety features, this shredder exemplifies reliability and innovation. By choosing SHREDALL, you're investing in a trusted partner for your metal recycling needs, committed to delivering superior quality and performance.

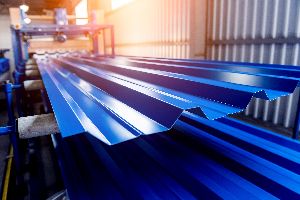

SHEET PROFILE MACHINE

Get Price Quote

1 Container (MOQ)

POLICORBONATED SHEET PROFILING AND CUTTING MACHINE TO MAKE VARIOUS PROFILES AS PER CUSTOMERS NEED.

metal welding machine

1,050,000 Per Piece

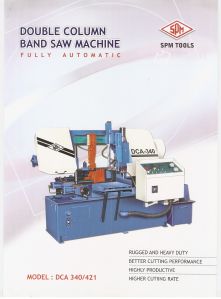

Metal Band Saw Machine (Capacity: 160mm, 200mm, 330mm)

Get Price Quote

We can offer you 3models of 'SPM' Double Column Heavy Duty High Speed Fully Automatic Band Saw Machine, model DCA160 - @yahoo.com

Sheet Moulding Press

Get Price Quote

Advanced Metal Detection System

350,000 - 725,000 Per Piece

1 Piece (MOQ)

Metal Label Marking Machine

Get Price Quote

We manufacture and supply the best quality Metal Label Marking Machine. The offered Metal Label Marking Machine is suitable for marking wide range of labels and tags. Metal Label Marking Machine, available with us, is precision engineered and ruggedly constructed. The Metal Label Marking Machine gives very sharp clarity. Model No. : LM40 Special Facilities Leaf gauge for multi-line labels. This special leaf-gauge can be custom-built to your individual need. It enables speedy alignment of each lines before marking!.... After marking a line, a leaf is flipped for immediate setting to mark in the next line! Stops for 2-lines labels Specially for 2-line marking, there are two stops (supplied with machine) to enables faster, accurate automatic alignment of each line before marking Features Marks Wide Range of Labels/tag : Perfectly marks Aluminium, Brass, Steel....almost every metal (especially effective in marking into windows of pre-printed labels!) Sharp Clarity Says ½high Quality½ : All marked data is sharply clear and easy-to-read; accurately aligned, evenly spaced and uniformly deep. Precision Engineered Has a rugged cast iron frame, specially hardened ground steel components and a unique dial wheel construction with interchangeable type inserts. Every feature is designed and engineered for long, trouble - free service. Versatility ideal when a wide range of label sizes need marking, when marking data varies, and when short production runs are required. Low Cost Too : Remember, this Bradma Diehard Metal Label Marker is a High Precision Tool Which means virtually no label spoilage, virtually no rejections. Result : Marking cost is considerably lower that that by tedious unrelable hand - stamping methods.Engineered for Long Life and Lasting Precision so easy to operate ! Takes just a few minutes on the machine to know to operate it! Basic 5-step Operation Simply set for marking depth. Locate label on marking table. Rotate dial wheel to select the character to be marked. Depress operating handle to mark label. Release operating handle - and the table automatically advances the label to the next marking position.

Automatic Metal Jotter Refill Filling Machine

Get Price Quote

1 Piece (MOQ)

Shutters Making Machine

Get Price Quote

we are the manufacturer of shutter making machine, These machines are designed with the proper bending

Expanded Metal Machine

Get Price Quote

The sheet is fed to the blades by means of rollers. A toothed upper blade cuts the sheet in conjunction with the straight stationary lower blade at right angle to the feed direction in such a way that a web of certain width remains standing which is stretched when the upper blade goes down. With the next stroke of the slide the cycle is repeated. The operation of Cutting - Stretching - Feeding is automatic.

Bench Metal Shearing Machine

Get Price Quote

We offer Bench Metal Shearing Machine. Hand Operated Precision Bench Shear with back guage.

Shielded Metal Arc Welding Machine

Get Price Quote

We are a leading Supplier, Exporter & Manufacturer of ARC Welding Machine. Our product range also comprises of Tig Welding Machine and MIG Welding Machine.

Metal Slitting Machine

500,000 Per Piece

1 Piece(s) (MOQ)

Metal Halide Horizontal Exposure Machine

Get Price Quote

Standard Features Oil less vacuum pump 0.5 HP. Reliable damper system (DC motor 1/b HP operator). Special electronic circuit makes machine user friendly). Digital pulse counter. Imported vacuum (Rubber) blanket for better contact between stencil & film . Automatic standby mode facility for power saving.Shutter release system helps screen to expose one after another without switching off the lamp. Metal Halide Lamp. Air blower for lamp cooling. Cooling system to keep glass surface cool. Hour meter for lamp. 10mm optically clear glass. Safety switch .

Boss Roofing Tile Forming Machine

Get Price Quote

Treadle Metal Sheet Shearing Machine

57,500 - 175,000 Per piece

1 Piece (MOQ)

We offer foot treadle operated guillotine shearing machine to cut shear 1250mm x 20 guage 0.9mm thickness mild steel sheets. treadle guillotine shearing machine are indispensable in sheet metal industries as they lead amongst all on account of versatile design, rigid construction, rigorous tests for the capacities and appearance. treadle shears are specially designed for rapid and continuous cutting of steel sheets of varied widths and trimming them in unlimited lengths. Features: *high tensile springs for quick return of treadle. *4 cutting edged hardened & ground quality blades. *rigid and streamlined construction. *spring loaded sheet holding device. *all steel fabricated construction body in every machine, the bed and top beam have full adjustments for correct setting and easy removal of blades for accurate cutting and for regrinding. The spring loaded pressure pad holds the the spring loaded pressure pad holds the perfect parallalism of cutting on either side. The adjustable front and back guages with running tee slots facilitate adjustment of various widths of the cuts and avoid any kind of twistings, turning of sheets while cutting. Square guide on the side of the table facilitates square cuts. The cutting edge blades avoid frequent grinding & adjustment and also very easy to grind to the rectangular shape for resharpening. these blades can be used with slight change in cutting angle to ribs, plastics, card board, rubber, mica etc., without any sign of squeezing or crushing. kindly contact for further details.

Expanded Metal Machine

Get Price Quote

Expanded Metal manufactured by slitting and stretching the material in one motion leaving a diamond shaped opening. It is widely used where rigidity, strength, light weight, & free passage of light & air is required. Used in Reinforcing material in Constructions, Air or Liquid Intake Screens, Architectural Designs etc .It is avalable in piece and varied size with choice of meshstrandgaugesheet or thickness. It is also used in High Tension Power & Oil RigsWalkways, Boiler, Machinery Plate,Form, Chemical Industry, Bridges, Staircases, Racks,Partitionetc.