shrinking machines

Get Price Quote

Shrink wrapping machines suitable for gift's confectionery, bottle, cosmetics etc. It's a high speed of sealing machine and high equipment sealing. The complete process is visible & is furnish with L- sealer shaped. The automatic process of shrinkable pouch complete with web- sealer. We are provide very high quality of heat-sealing machine and branded shrink machines. It's very easily used.

Automatic Shrink Wrapping Machine

600,000 - 720,000 Per Bag

Best Deals from Shrinking Machines

Shrink Wrapping Machines

Get Price Quote

Steam Shrink Tunnel Machine

280,000 Per Piece

Shrink Wrapping Machine

Get Price Quote

Shrink Wrapping Machines

Get Price Quote

Shrink wrapping machine is majorly used to wrap objects with filmShrink tunnels are of different sizes to apply on various product sizesShrink wrapping machine is consited of shrink tunnel of 8 to 36 “ tunnel size in width.Shrink tunnels are widely used to wrap objects with shrink sleeves.Shrink warpping machine can be used as sleeve labelling machine to apply sleeves on packaged drinking water, glass bottles.Shrink sleeve labelling is major use of shrink tunnel to get better labelling machine accuracy.Different types of shink tunnels can be designs to apply sleeves on bottles with various shrink wrapping machines.Shrink packaging is a method of applying skin tight labelling on bottles.Shrink wrapping equipments are widely used in food packaging & pharmaceutical packaging.PVC shink labelling machine and Pvc shrink sleeve applying is similar machine applications.Shink tunnel is suitable for PVC shink labelling and Pvc shrink sleeve applying . Technical feature :* Two large power blowing blows ensure enough circulating air;* Conveying speed is controlled by the imported frequency inverter;* A baffle is fixed both on the entrance and exit of the tunnel, prevent the heat inside the tunnel going out;* The imported insulation curtain lowers the waste of the heat inside tunnel;** The tunnel's height can be adjusted by the ground bolt to meet different height of the production line;* The S/S heaters increase the temperature fast and they can be used for 5-10 years;* The worm gear reducer and large power motor ensure the stable conveying;* There are four wheels on the bottom of the machine, so can move machine freely;* Specially designed wind path makes the products shrinked evenly;* Adopts adjustable wind mesh panels inside the tunnel, the blowing wind is adjustable;* Adopts large power cooling blower, makes products cooled and formed in a short time. Max. Machine dimension L×W×H(mm) 2800×970×1400 Max packing size L×W×H(mm) 1000×400×250 Worktable height 750mm Packing speed (pcs/h) 3000-5000 Power (kw) 21 Machine weight 350kg Power supply 3φ220V/380V 50/60Hz Suiatble to wrap any object,box,bottles with shrink film Compac design with Air Cooled sytem SS mesh passing conveyor Available in 5x8", 6x8", 12x12" & 16x16" tunnel sizes Adjustable temp & conveyor drive Speed: 10 packs per Minute

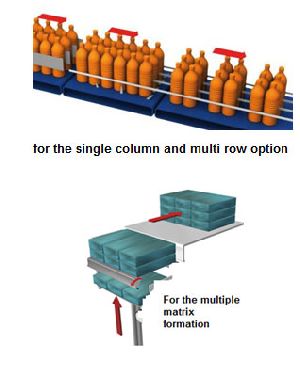

Straight feeding Shrink Wrap Machine

Get Price Quote

In a Straight feeding Shrink Wrap Machine The products which are planning to shrinkwrap will travel in a single line , inline to sealing unit and the products will collate on collation plate and pneumatic pusher which pushes the products onto sealing units (web sealer) but such option is possible only for the single column and with multiple row option i.e 1x1,1x2, 1x3,..1xn If you have multiple columns and rows then need an vertical pusher i.e for the matrixes 4x4, 3x4, 5x4 …nxn. Accordingly the machine size and pusher size infect all change parts will very and the packing time also In a single column and multiple row options a pneumatic pusher collates the boxes / containers into the pre-selected pack formation plate, which upon completion is transferred forwarded into the welding position. In and multiple row and column option there will two or multiple pusher to collate and form the matrix Once the required matrix gets formed by respective pushers as per set product size the pusher advances to push the formed matrix to sealing unit , once the matrix reaches the forming unit or forming plate the sensor gives the signal to welding bar accordingly it descents to complete the wrap, and the pusher returns to prepare the next collation of product. As the welding bar ascends, the pusher advances to transfer the new collation into the welding position, at the same time displacing the previously wrapped collation onto continuously moving shrink tunnel conveyor. The wrapped collation soon enters the shrink tunnel chamber where re-circulated hot air causes the wrap to shrink and tightly conform to the contours of the contents. Once the pack is out of the hot chamber, forced air cooling is used to tighten sleeve wrap to achieve a strong, secure pack ready for stacking on pallet or a placing on a shipping carton.

Thermal Shrink Packaging Machine

42,500 Per Piece

Nido Shrink Packing Machine

Get Price Quote

2 in 1 Shrink Wrapping Machine,Semi Automatic L-Bar Sealer + Shrink Tunnel,Automatic L-Bar Sealer + Shrink Tunnel,Automatic Side Sealer + Shrink Tunnel,Semi Automatic Sleeve Sealer + Shrink Tunnel,Fully Automatic Sleeve Sealer + Shrink Tunnel