Temperature Transmitters

A temperature transmitter is a device that connects to a temperature sensor to transmit the signal elsewhere for monitoring and control purposes. Typically, the temperature sensor is an RTD, Thermisor or Thermocouple type sensor and will interface with a PLC, DCS, data logger or display hardware. The temperature transmitter's role is to isolate the temperature signal, filter any EMC noise, amplify and convert the temperature sensor's signal to a 4-20mA or 0-10V DC range for further use. Silent Features Smart head transmitter that accepts thermocouple temperature sensors and converts sensor output over a configured range to a standard industrial (4 to 20 mA) transmission signal. Two-wire Operation Power is obtained directly from the 4 to 20 mA loop, with no need for separate power input. This simplifies field wiring and eliminates the possibility of noise pickup from power lines. RTD andThermocouples with various combinations of length and outersheath with rapid response to withstand pressure, erosion andvibration environment. RTD & Thermocouples are manufacturedin accordance with national and international standards such asANSI MC96.1, IEC 584, IEC 751, DIN 43670 class A & B. Die-cast Aluminium, Weatherproof to IP-65RTD / Thermocouples Assemblies suitable for Temp. Single Entry of cable with cable gland in SS304. Precision industrial RTD&Multipoint RTD / Thermocouples Assemblies MOC : Stainless Steel 304 Type: Simplex type with transition teflon/teflon cable of length 5 meters. Element: Pt-100 3 Wire Type standard (Also available 2 -wires Type, please select request for customization) Output: 4-20mA.

...more

Screw Compressor

The tank-mounted air compressor is especially suitable for location near the application of the compressed air or as an extension to existing installations. Main part of Screw Compressor is Air-end, consisting of a pair of rotors. The male rotor is driven by electric motor. Suction of air though Inlet filter and suction control valve. Air – oil mixture from air-end flows into an air – oil separator. The separated oil flow through oil filter and after cooling in 'cooler', it gets back into the system. The air also passes through air cooler and to the receiver. The whole system is controlled through valves / sequence of compressor is done through electric /electronic control. Excellent quality compressed air, outlet compressed air oil content less than 3ppm, suitable for all main industry area. Factory tested complete compressed air system use of world class rotary screw elements, designed for continuous operation. Silent Features: Stable Air Flow Volume, Less wear Parts than Piston Compressor, High Reliability Industry-leading performance delivers more air for less horsepower, saving thousands of rupees per year on energy. Maximum Uptime Quiet operation allows for installation closer to point-of-use, reducing costs and ensuring a better & safer work environment. Compact, High-efficiency & Low-noise

...more

Refrigerator Air Dryer

High efficiency integrated heat exchanger with low pressure loss. High level of efficiency for maximum power saving. Environment friendly refrigerant. Low pressure dew point. Optimum condensate separation. Minimum space requirement. Easy installation and maintenance.

...more

Reciprocating Air Compressor

Designed for heavy shop or industrial use, Electric-driven Single stage &Two-stage air compressors are made of heavy-duty components to give optimum performance. These compressors have two different sized cylinder bores. Robust design crankshaft for reliability and easy maintenance, solid end connecting rods, high thermal efficiency, inter-cooling, totally reliable splash lubrication and balanced V-type construction for smooth & vibration-free operation. Silent Features: Durable cast iron design for 100% continuous duty application Precision engineered components for high reliability Individually cast cylinders, overhung crankshaft and one piece connecting rod for ease of maintenance and service High efficiency finger valves 175 psig maximum operating pressure for applications requiring high air capacity and pressure. Ideal for most applications and users including automotive service and body shops, fleet maintenance, machine shops, production and manufacturing lines, dry cleaners, car washers, general maintenance/repair shops etc. Standard Scope of Supply for Complete Package: Bare compressor Air Suction Filter Air Receiver (vertical or loose supply) Receiver Fittings like: Safety Valve, Pressure Gauge, Service Valve, Drain Valve, Pressure Switch / Auxiliary Valve ASSC / CSC Regulation V-belts & Belt Guard Motor Pulley & Motor Slide Rail Motor & Starter Flywheel Low Oil Level Switch Compressor also available as : Base Plate Mounted – Portable, Tailor- made package

...more

Pressure Transmitter

A pressure transmitter is a measuring device which converts an applied pressure into an electrical signal. Generally, a pressure transducer consists of two parts, an elastic material which deforms under the application of pressure and an electrical part which detects this deformation. Silent Features Available in varying measuring range. Available in all size of process connection Power supply: DC 8...35 V Permissible medium temperature: -30...+100°C Overpressure Safety Straight & Angular Electrical connections Output: 4 -20 mA 2 Wire Accuracy: +/- 0.50 % of span It is the ideal pressure sensor for customers with demanding measuring requirements in Machine building, Hydraulics and pneumatics, Pumps, Chemical industry.

...more

Pressure Regulator

A pressure regulator is a control valve that reduces the input pressure of a fluid to a desired value at its output. Regulators are used for gases and liquids, and can be an integral device with an output pressure setting, a restrictor and a sensor all in the one body, or consist of a separate pressure sensor, controller and flow valve. Domestic PRV: These regulators are mainly used for household purpose and are suitable for single burner / two burner gas stoves having total consumption of 500 ltr/hr of LPG. These Pressure Regulators are suitable to reduce inlet pressure of 0.5-5 bar working pressure to 21 mbar. Industrial Preset PRV: These regulators are having preset outlet pressure. However the outlet pressure can be slightly adjusted by rotating the spring adjusting screw. These pressure regulators provide sensitive control at low downstream pressure. The diaphragm type construction assures responsive regulation up to inlet pressure of 17 Kg/cm2.These are suitable for hotels, small&medium industrial appliances. Pilot OperatingPRV: These are more accurate & offer higher capacities than the standard direct operated spring loaded regulators. It maintains a constant outlet pressure even in large variation of inlet pressure and flow rates.

...more

portable gas detectors

Portable gas detectors utilize the latest infrared gas detection technology in a robust and reliable design. It provides intelligent data-logging functionality combined with optional GPS mapping to simplify data gathering and easily syncs with our cloud based Instrument Management System (IMS) to support reporting and compliance. The natural gas discrimination feature quickly determines the source of gas leaks, whether it’s pipeline gas or naturally occurring biogas; saving valuable time and reducing detection related costs. Applications Gas leak outdoors Pipeline gas tests Purging Surveying Bar-holing Confined space monitoring

...more

Motor Driven Compressor

We believe in significant reduction in maintenance costs resulting in an increase in reliability and availability of machine. Our comprehensive technical expertise and domain knowledge helps to provide one of the best, reliable and efficient Gas Compression systems to the clients to improve processes, productivity and maturity of their QA organization. Motor Driven CNG Compressor High flow rate compressors for motherCNG stations& daughter CNG stations and other Oil & Gas applications. Lube & Non-lube with Continuous duty application. 2/3/4/5 stage CNG Compressors having capacity of 550/600/750/950/1200/2400 SCMH Available for different Suction Pressure: 7– 70 kg/cm2. Maximum Discharge pressure: 255 kg/cm2. Motor (Reputed Make) capacity: 90 to 400 KW Drive Arrangements will be direct coupled/V-belt (Anti static fire retardant type drive belt) Area Classification: Class I Div I Group D or Zone I Div I group IIA/IIB. Air/Water Cooled heat exchanger for interstage discharge gas. 4/6/9 bank priority panel with MFM at suction & discharge with common structure steel skid for the compressor – motor combination & for all auxiliary system. Provided with impulse & pneumatic piping / tubing for all valves, fittings required for mounting the instruments. Separate JB’s for different type of signals like intrinsically safe signals, alarm, shutdowns, thermocouples, RTD’s etc. for interfacing to local panel. Acoustic enclosure for compressor package, with one or more than one number of L.E.L detector and UV detector. Inlet and outlet manual & automatic valves for maintenance and emergency Duplex suction filters at the inlet of the package with DP gauge after Y type strainer Two stage filtration at discharge, so as to limit oil carryover.. Motors above 10 HP with star delta/soft starter (3 phase controlled type starter) All controls shall operate in fail safe mode.All exposed rotating parts will be provided with adequate guards. Relief valves will be providedat suction and discharge and each inter stage of compressor. All the interlock, monitoring and controlling of the CNG compressor package is done through PLC based control system of proven type and theMake of the PLC isSiemens(S7 300), SchneiderM340 PLC and Allen Bradley (Micrologix 1200) of latest version or equivalent. Panel complete with start and stop push buttons, hours run meter, power on and fault indication lamps, and fault reset button and HMI (Siemens / Schneider make). The PLC has an Industrial Ethernet Module with min TWO Ethernet port and Modbus RS-485 (2-wire) port, Configured and programmed, to establish remote communication of PLC with the SCADA server. The parameters such as gas Inlet Pressure, discharge pressure, discharge temperature, Hydraulic Oil Pressure, Hydraulic oil Temperature, Hydraulic oil level, Water Pressure, Water Temperature, Running hours & Electrical Parameters like the Power Factor, Voltage, Current data is displayed on the HMI.

...more

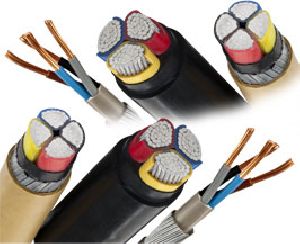

Lt Control Cables

Armoured & Unarmoured

Hydraulic Compressor

CNG booster compressors& associated accessories including electrical panel, radiator, air compressor etc. These CNG booster compressors are equipped with programmable logic controller (PLC) and shall be SCADA compatible. Suction Pressure: 200 to 30 bar (G) Discharge Pressure: 250 bar (G) Average flow capacity: 500 SCMH Suction Temperature: Nominal 35ºC, Max. 45ºC Discharge Temperature: Max 8ºC above ambient Ambient Temperature: 48ºC Maximum Medium: Natural Gas, Dry, SG – 0.58 to 0.65 Type: Hydraulic operated cylinders Configuration: Multi stage double acting Lubrication: Non lubricated Valves: Suction & Delivery Valves Gas meter: Mass flow meter based on Coriolis principle Driver: Electric Motor Drive: Hydraulic Motor :(i)Main Motor (ii)Water Pump (iii)Radiator (iv)Air Compressor (v) Exhaust fan Cooling: Water cooling to Gas Heat Exchanger Tube in Tube type Control Panel: Starter and Control Panel with Star/ Delta starter Controls: PLC Control, Auto Start / Stop ON PR. Setting Manual Draining Instrumentation: PR. / TEMP. TRIPS, Gas leakage and fire trips Vessels: Discharge Pulsation Dampner Packaging: Complete Compressor Unit Fabricated on a Single Skid to make a Single operating unit considering ease of maintenance Priority panel: 2-bank Configuration priority provided Gas Detector & Flame Detector provided of approved makes Door interlocked isolator Panel complete with start and stop push buttons, hours run meter, power on and fault indication lamps, and fault reset button and HMI (Siemens / Schneider make). All necessary timers and intrinsically safe relays to control the system on an automatic starting and stopping basis All the interlock, monitoring and controlling of the CNG compressor package is done through PLC based control system of proven type and the Make of the PLC is Siemens(S7 300), Schneider M340 PLC and Allen Bradley (Micrologix 1200) of latest version or equivalent PLC is housed inside flameproof IIA/IIB (Ex’d’) enclosure. Local operator panel is provided on the flameproof enclosure. The operator panel is provided for parameterization, indication, monitoring, and alarms and first out sequence of the system. PLC system have memory modules for storing user programs, symbol lists, Program comments and should facilitate debugging / trouble shooting without the application program. Program is ladder logic and communication is in English for each run. The Protocol and the other details for Interfacing is specified clearly. The Communication protocol is an open protocol i.e. MODBUS RTU Protocol for communicating with slave devices. Power supply to PLC supply is 24 VDC. The PLC has an Industrial Ethernet Module with min TWO Ethernet port and Modbus RS-485 (2-wire) port, Configured and programmed, to establish remote communication of PLC with the SCADA server.

...more

Heatless Air Dryer

Operation on ADSORPTION principle: Hence prevent entrainment of moisture in the pipe line however long it may be. The most compact skid mounted unit supplied in ready for use state by connecting compressed air at inlet and outlet. The stationary working system requires negligible maintenance. Assured atmospheric dew point equal to -40 deg C or -70 deg C is required. Ideal purging as per desiccant manufacturers instruction for regeneration. Lesser pressure drop in total unit. Modified purging silencer causes less noise. Designed for Indian atmospheric conditions. Easy for installation and commissioning

...more

Flow Meters

A flow meter is a device used to measure the flow rate or quantity of a gas or liquid moving through a pipe. Flow measurement applications are very diverse and each situation has its own constraints and engineering requirements. You can measure flow through a variety of different devices such as Coriolis and positive displacement meters.

...more

Flame Detector

A flame detector is a sensor designed to detect and respond to the presence of a flame or fire, allowing flame detection. Responses to a detected flame depend on the installation, but can include sounding an alarm, deactivating a fuel line (such as a propane or a natural gas line), and activating a fire suppression system. When used in applications such as industrial furnaces, their role is to provide confirmation that the furnace is properly lit; in these cases they take no direct action beyond notifying the operator or control system. A flame detector can often respond faster and more accurately than a smoke or heat detector due to the mechanisms it uses to detect the flame. Applications Hydrocarbon stations. Gas-fueled cookers Industrial heating and drying systems Domestic heating systems Industrial Gas turbines

...more

Engine Driven CNG Compressor

157 - 324 hp / 117 - 242 kW@ 1800 rpmhigh-performance natural gas engine – Rugged,Inline 6-Cylinder, 4-Cycle, Natural Gas, spark ignited engine delivers reliable power, low emissions, and fast response to load changes Gas engine will be of Caterpillar or Cummins Make. The gas engine is equipped with the following Water cooled exhaust Manifold. Naturally aspirated / Turbo charged Intercooled design. Water cooled Turbo charger exhaust housing. Engine driven Radiator fan and radiator assembly. Auxiliary water cooling system. Approved ignition system. Electronic air fuel ratio controller/ Electronic gas carburetor Electronic / Mechanical governing system. Inline / V type configuration. Six / Eight cylinder configuration. Air starting system. High flow rate compressors for motherCNG stations & daughter CNG stations and other Oil & Gas applications. Lube & Non-lube with Continuous duty application. Blow down vessel which acts as buffer tank during start up. & used as a surge tank for depressurization of each compressor stage piston cylinder during shutdown. Rotational speed of compressor & engine shall be limited to maximum of 1650 RPM 3 no’s of gas flow meters to measure the natural gas consumption at Package inlet , package discharge, fuel consumption at gas engine inlet. NRV at final discharge. Compressor will trip on detection of gas / flame at present level and automatic discharge of co2 gas will take place from main cylinder. 2/3/4/5 stage CNG Compressors having capacity of 550/600/750/950/1200/2400 SCMH Available for different Suction Pressure: 7– 70 kg/cm2. Maximum Discharge pressure: 255 kg/cm2. Engine (Reputed Make) capacity: 90 to 400 KW Drive Arrangements will be direct coupled/V-belt (Anti static fire retardant type drive belt) Area Classification: Class I Div I Group D or Zone I Div I group IIA/IIB. Air/Water Cooled heat exchanger for inter stage discharge gas & Engine Jacket. 4/6/9 bank priority panel with MFM at suction & discharge with common structure steel skid for the compressor – motor combination & for all auxiliary system. Provided with impulse & pneumatic piping / tubing for all valves, fittings required for mounting the instruments. Separate JB’s for different type of signals like intrinsically safe signals, alarm, shutdowns, thermocouples, RTD’s etc. for interfacing to local panel. Acoustic enclosure for compressor package, with one or more than one number of L.E.L detector and UV detector. Inlet and outlet manual & automatic valves for maintenance and emergency Duplex suction filters at the inlet of the package with DP gauge after Y type strainer Two stage filtration at discharge, so as to limit oil carryover.. Motors above 10 HP with star delta/soft starter (3 phase controlled type starter) All controls shall operate in fail safe mode. All exposed rotating parts will be provided with adequate guards. Relief valves will be providedat suction and discharge and each inter stage of compressor. All the interlock, monitoring and controlling of the CNG compressor package is done through PLC based control system of proven type and theMake of the PLC isSiemens(S7 300), SchneiderM340 PLC and Allen Bradley (Micrologix 1200) of latest version or equivalent. Panel complete with start and stop push buttons, hours run meter, power on and fault indication lamps, and fault reset button and HMI (Siemens / Schneider make). The PLC has an Industrial Ethernet Module with min TWO Ethernet port and Modbus RS-485 (2-wire) port, Configured and programmed, to establish remote communication of PLC with the SCADA server. The parameters such as gas Inlet Pressure, discharge pressure, discharge temperature, Hydraulic Oil Pressure, Hydraulic oil Temperature, Hydraulic oil level, Water Pressure, Water Temperature, Running hours & Electrical Parameters like the Power Factor, Voltage, Current data is displayed on the HMI.

...more

Electrical Control Panels

An electrical panel is also called a load center. It is a metal electrical service box that accepts the main power to the home/office/service area and distributes electrical current to the various circuits within the Home/office/ Service area. Also known as: Load Center, Service Panel, Breaker Panel, Fuse Box.The distribution of power to the various circuits is protected from over-current by the use of circuit breakers or fuses. These Electrical Control Panels are widely used in different places such as Telecom sector, Oil & Gas sector, Power Sector and others as per the need of the clients. Our offered panels are available in various specifications in order to attain maximum clients' satisfaction. Moreover, these panels are delivered to the clients at reasonable rates. Sicom Sales & Engineering is a team of qualified dedicated engineering professionals having a rich experience in the field of power electronics. The company firmly believes in delivering total customer satisfaction spanning from concept todesign, commissioning to after sales service. We offers fully engineered & cost effective solutions for process Automation & controls , integrating Digital DC Drives, PLC with networking & interfacing with process computers/ HMi’s.

...more

cng pressure regulator

A pressure regulator is a control valve that reduces the input pressure of a fluid to a desired value at its output. Regulators are used for gases and liquids, and can be an integral device with an output pressure setting, a restrictor and a sensor all in the one body, or consist of a separate pressure sensor, controller and flow valve.Domestic PRV: These regulators are mainly used for household purpose and are suitable for single burner two burner gas stoves having total consumption of 500 ltrhr of LPG. These Pressure Regulators are suitable to reduce inlet pressure of 0.5-5 bar working pressure to 21 mbar.

...more

Cng Pressure Reducer

A pressure regulator is a control valve that reduces the input pressure of a fluid to a desired value at its output. Regulators are used for gases and liquids, and can be an integral device with an output pressure setting, a restrictor and a sensor all in the one body, or consist of a separate pressure sensor, controller and flow valve.

...more

CNG Dispenser Spare Parts

Mother Board Totalizer Filling Hose& Vent Line Hose NZS & NGV Nozzle Three Way Ball Valve Actuators Solenoid Operation Valve Filters Drain Valve Pressure Gauge Pressure Transmitter Emergency Swich On-Off Knob Nozzle O-rings

...more

Cng Dispenser

Full automatic microprocessor based sequencing of 3 cylinder banks connected to dispenser through independent high pressure Stainless Steel (SS) tubes. Dispenser to have pressure control device to restrict fill pressure to 200 barg at maximum allowable filling pressure for natural gas vehicle cylinder. Pressure control device to ensure complete shut off of gas flow at the pre-set pressure with dead band shift and shut off error within 2% of range. The pre-set fill pressure can vary from 150 barg to 250 barg. The pressure control device have provision to manually set pressure between above range. General construction & Assembly: All component used in compressed natural gas dispensing equipment is listed by a nationally recognized certification agency as complying with an applicable standard, or evaluated by the certification agency for the intended application as part of the dispensing equipment.

Type : 3 line electronic Dual hose

...more

CNG Compresor Spare Parts

1st, 2nd& 3rd stage piston ring kit 1st, 2nd& 3rdstage rider ring Tangential, radial seat kit Pressure Breaker Ring Oil Scrapper ring kit Oil Seal Diaphragm for De-pressurizing Valve Non Return Valve Seal kit for Regulator Seal kit for NRV 1st, 2nd& 3rdstage inlet valve& outlet valve Repair Kit for 1st, 2nd& 3rdstagevalve CR Big end bearing&Bushing for connecting rod (small end bearing) Connecting Rod-Crosshead Pin Crosshead &Deflector Ring Flywheel side bearing cover Washer for crankshaft Counter weight Pump side bearing cover Piston Assembly 1st, 2nd& 3rdstage Non return valve for oil Gear Pump Assembly & its repair kit Oil sight glass assembly Air/Gas & Oil Cooler Cranckcase Breather Clearance pocket guide bush&piston rings Lubrication system, Oil Distributor& its repair kit Seal cover Cranckshaft Coupling 1st, 2nd& 3rdstageCylinder Piston Assembly for 1st, 2nd& 3rdstage(Piston+piston rod+washer+nut+screws) Safety relief valve Seal kit for ball valve O-ring kit& Copper gasket kit Flywheel Gear pump assembly NRV Sealkit Priority Panel Thrust washer - Main Bearing Lube oil level switch

...more

Auto Drain Valves

The entrainment of condensate along with air flow in compressed air system to end use applications is extremely harmful, if system not drained regularly. The ideal solution for regular effective draining oil & moisture form compressed Air System is Electronic Auto Drain Valve. (E A D V). Silent Features: Easy replacement of timer card only and not full assembly. Longest drain time frequencies for saving compressed air energy. Individual application capacities like receivers, filters and separators etc. Longer service life by way of having supplied with inlet 'Y' type strainers. Technical Specifications Cycle time: 10 to 90 Minutes (Adjustable). Drain time: 1 to 10 Secs (Factory set 5 Secs). Working Pressure: Max 12 Kg. / cm2g. Working temp: 70 Deg C max. Elect. Supply: 230 V-1ph - 50 Hz. Housing: Weather Proof / Shock Proof (Powder Coated). Timer Display - Digital

...more

Air Receiver Tanks

Compressed Air Receivers plays very important role in compressed air system with multi purposes by value of its design and rightly selected. Compressed Air Receivers or Air pressure Vessel also enhance the service life of compressor. The receiver tank acts as a reservoir of compressed air for peak demands. The receiver tank will help remove water from the system by allowing the air a chance to cool. The receiver tank minimizes pulsation in the system caused by a reciprocating compressor or a cyclic process downstream.

...more

Air Dryer Spare Parts

Solenoid Valves (Main) Purge Valves Spare Elements PF (Pre-filter) Spare Elements FF (Fine-filter) Spare Elements AF (After-filter) Desicant Drysorb-303 Diffuser Timer Card Solenoid Valve Coil Gasket Set O-ring Set Sintered Silencer Relay OLP Capacitor Compressor Fan Motor Capillary Tube Solenoid Valve Refrigerant Gas Are You Lo

...more

Air Compresor Spare Parts

O'ring, Oil Filter Plug Gasket, Frame End Cover Connecting Rod Seal, Oil Gasket, Shaft End Cover Crankshaft Assembly with Bearing Belt V Bushing, Cranckpin Key, Woodruff Assembly, Valve Plate HP & LP Plate, Valve HP & LP Valve, Finger-Inlet HP & LP Retainer, Finger Valve-Inlet HP& LP Retainer, Finger Valve-Discharge HP& LP Valve, Finger-Discharge HP& LP Dampner, Valve HP & LP Head, HP & LP Gasket set HP & LP Head O-ring HP & LP Gasket, Flange Assembly, Piston/Pin HP& LP Ring, Compression-HP & LP Set Valve Safety 60 PSIG Filter, Inlet-Complete Element, Filter-10 Micron Valve Safety 1/2 X 190 PSIG Check Valve Pulley, Motor 1000 RPM

...moreBe first to Rate

Rate ThisOpening Hours