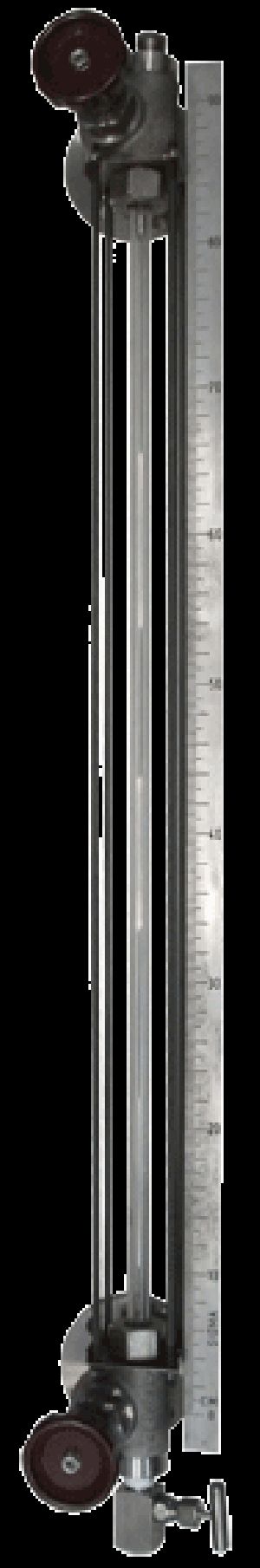

Tubular Level Gauge

SIGMA's Tubular Gauge Assemblies consist of a pair of Steel Gauge Cocks preferably forged, complete with four (4) Guard Rods or 2 nos C protectors, Guard Rod Holders and Borosilicate Tubular Glass. The Gauge Cocks have Union Bonnets, Stainless Steel Trim, Screwed Renewable Seat, Stainless Steel Ball Checks to automatically shut off the flow of the process fluid in case of glass failure. The Stainless Steel Stem is fitted with an extension tip to unseat the ball check when the valve is in the closed position. Gauge Cocks have Union Connections at valve ends for easier assembly and installation. The Tubular Glass Connections are Stuffing Box Type with a packing bush to prevent torsional stress on the tubular glass when gland nuts are tightened. Gauge Cocks are furnished with Handwheel Operation.

...more

Transmitter

SIGMA's Magnetic Float Operated Level Transmitter is a simple and reliable technique for continuous level indication and control of any liquid, chemically compatible with the (sensor) material, unaffected by electrical conductivity, temperature, pressure or viscosity. The float is designed for variety of liquids.The Transmitter consists of a float & guide stem assembly in non-magnetic material to achieve undisturbed flux. A chain of closely spaced glass encapsulated reed switches & resistors are placed inside the guide tube. During rise and fall of liquid level, the magnetic float moves & actuates a reed switch in the chain. The sensed voltage is fed to the transmitter located in the enclosure for conversion to a signal of 4-20 mA.

...more

Top Mounted Level Switch

Severity, adversity... whatever the conditions of environment, SIGMA liquid level controllers keep operating. Rugged design of our units offer an electrical compartment completely isolated from the product level to be monitored. This makes it to withstand the extremely severe conditions to be met with in a wide range of a wide range of Chemical, Petrochemical, Power and other Process industries. A wide range of SIGMA level controllers in an application bound material mix provide choice for one, two, three or four level monitoring by trigger related systems through contactors or relay. The level sensor termed as displacer is designed to suit high temperature and pressures. With wide differential models, the use extends to open tanks, slurry and treatment plants, neutralization pits etc.

...more

Sight Flow Indicator

SIGMA's Sight Flow Indicator (Flow Glass) are designed to facilitate instant visual indication of liquids flowing through pipes even from a distance. Visual inspection and proper control of vital areas are important in processes for proper operation of well-designed plants. These are available in various types such as Flapper, Drip Lip, Full View, Elbow etc. with Double or Single windows in Flanged or Screwed and other end connection. For ease of installation, Flanged Type for sizes 3" and above are preferred

...more

Side Mounted Level Switch

SIGMA's Float Level Switch are compact solutions to monitor low, intermediate and high level in tanks. This rugged, quick mounting & maintenance free design is an instant choice for tanks with high insertion depths or inaccessible top and bottom. A small pivoted float forms the only sensing probe that projects within the tank. Typical applications of these sensitive and accurate devices include strong tanks, high-pressure boilers, sterilizers and process tanks.

...more

PNEUMATIC LEVEL SWITCH

SIGMA's Pneumatic Level Switches are used in application where electrical switching is not recommended or electricity is not available. The working principle is the same, except that the magnet indirectly actuates a 3/2 valve for changeover. This 2 system requires minimum 2 kg/cm clean filtered air, preferably through an AFR. Side Mounted (with / without cage) : Buoyancy force of process liquid on a float causes the float to move with the liquid's surface. Float movement pivots a magnet into the field of a like-charged switch magnet. As the magnets repel each other, the switch magnet moves, actuating the switch. Top Mounted :Float / Displacer (with / without cage) : Operation is based upon simple buoyancy, whereby a float or a spring loaded weighted displacer rises following the liquid level. A magnetic sleeve, connected to the float / displacer, moves up and operates within a non-magnetic enclosure tube. The magnetic sleeve attracts a pivoted magnet, actuating a switch mechanism located out-side the enclosure tube to give NO or NC changeover. A fall of liquid level will de-actuate the switch mechanism

...more

Oil Level Gauge

SIGMA’s Oil Level Gauge / Indicators (Acrylic) are designed for measuring / indication of level of oil or other transmission liquids. The principle of operation is liquid maintaining its level by virtue of gravity. The Oil Level Gauge comprises of a solid block of transparent acrylic (oil chamber) with graduations as required. The Oil Level Gauge is connected to the storage tank through a single limb or by having two connections drawn from the chamber to the side of the tank. It also contains a vent and a drain. This is typically used for low pressure and low temperature applications.SIGMA’s Oil Level Gauge / Indicators (Glass) is rugged, compact and reliable gauge for visual indication of oil levels in small tanks. The Level Gauge consists of a toughened borosilicate gauge glass tube fitted between metallic end blocks and banjo bolts through a set of o-rings. A slotted steel guard is provided enclosing the glass guage to provide protection from accidental damage. The gauge is mounted parallel to the tank, to form a closed loop causing tank liquid to seek its level in the gauge.

...more

Needle Valves

SIGMA’s Needle Valve are available in two way, three way, multiport, single block & bleed, double deck and bleed. These Needle valves are available in variety of end connections screwed male/female pipe ends which confirm to ferrule designs. Valves as per custom needs with any end connections, for pressure ranging from 10 kg/cm2 to 700 kg /cm2, can be offered. Isolation needle valve upto 10000 PSI are available for hassle free long life in process lines. These valves can be used to isolate, calibrate and drain the process lines.

...more

three valve manifolds

SIGMA’s Manifold Valves provide a safe, conventional method of isolating, blocking, bleeding and calibrating instruments, meters and pressure transmitters. These valves are available in numerous body, bonnet and seal configurations with NPTF, Tube Fittings and / or instrument flange connections. The manifold valves operate up to 415 kg/ sq.cm. Choice of manifold valve with different body patterns and hard seat models utilizing either a vee, ball or non rotating stem etc are available.

Size : 5-10inch

Material : Metal

Weight : 5-10kg

Color : Grey

Feature : Durable, Good Quality

Connection : Butt Weld, Screwed

...more

magnetic level gauge

SIGMA's Magnetic Level Gauge provides level indication in a range of operating conditions. It offers maintenance- free, preventive security against leakage, environmental safety, sure and trouble free application against chemically aggressive, harmful or poisonous, inflammable or explosive, pollutants or optically similar fluid interface.Sigma magnetic level gauge consists of a float chamber, a float, and an external indication device. An engineered float travels inside the gauge and follows the vessel level. The float carries an internal magnet that simply "flips" the flags thus indicating the level. The flags remain flipped until the float returns in the other direction. The magnetic level gauge is unique in that if the flag display is hit nothing will leak as they are magnetically coupled to the float. The float type is determined by the process fluid specific gravity, pressure and temperature. The materials of construction must be compatible with the process fluid. Each float is engineered for proper buoyancy for each particular application for level or interface measurement.

...more

reed level switch

SIGMA's Float operated Reed Level Switch are ideally designed for liquid level indication in tanks. The design is simple and compact. Typical applications are water, diesel, chemical storage and hydraulic tanks. The level switch consists of a sealed tube inside which hermetically sealed Reed Switches are placed at points where switching operations are required. The magnetic float raises / falls with the liquid level and operates / re-operates the Reed Switch (make or break on rise / fall of liquid level specified). The REED Type Level Switch is available in Top Mounted and Side Mounted Version.

...more

Instrumentation Fittings

torque free seal at all tubing connections. Fittings confirm to ANSI 31.1, ANSI B 31.2, ANSI Sec VIII and BS 4368.SIGMA's Pipe Fittings are designed for high pressure applications on hydraulic and pneumatic lines, fittings are manufactured upto a rating of 10000 PSI as per DIN 2353 & FS 8801 - 8805 standards. Forged fittings as per ASME B 16.11.

...more

Flow Switches

SIGMA's Flow Switch is an extension of the level switches. There are two types of flow switches : one for low flow / line size up to 50 mm line size (Model FS 1000) and another from 25 mm onwards up to 800 mm or above (Model FS 1010).Operating Principle :Model FS 1000 is a valve type Flow Switch wherein an increase in flow through the body raises the valve disc depending upon the flow. This in turn raises the magnetic sleeve moving inside a non-magnetic enclosure. The movement of the sleeve attracts the magnet located outside the tube which in turn actuates a micro switch. Decrease in flow reverses the action.Model FS 1010 is a target type which moves from a vertical position to a near horizontal position as the flow increases. This change in position moves a magnetic sleeve in a non-magnetic enclosure. The movement of the magnetic sleeve attracts a magnet which in turn actuates a micro switch. Decrease in flow brings the target back to the vertical position.

...more

Float Level Indicator

SIGMA's Tank Level Indicators are float operated target type suitable for liquid level gauging of fixed roof, floating roof, open type vertical storage tanks and underground sumps for water, oil, solvents etc. The tank level indicators are of simple construction and are easy to install. They are very sturdy and require no maintenance. A float operated tank indicator comprises of a float that is located within guide cables. The guide cables whose ends are fastened on to an anchor bar are kept straight and wrinkle free by tension devices. The anchor bar is either grouted or welded to the tank bases. The float cable is wound over a set of pulleys, which are secured in the pulley housing. One end of the float cable bears the float and the other end carries a pointer assembly with a counter weight for balance. Tank level indicator float operated type is for fixed roof, floating roof, open top and under ground storage tanks.

...more

external cage level switch

SIGMA's External cage liquid level switches are very widely used for the petroleum and power industries. Anti vibration design ensures positive switch activation. Being highly versatile, cage mounted type extends to a wide range of other possible applications.A pivoted permanent magnet end is attached to a micro switch. As the float rises following the liquid level, it raises a Magnetic sleeve (isolated inside a non magnetic enclosure (barrier) tube) into the field of the magnet causing attraction and movement across the pivot, actuating the switch. The enclosure tube provides a static seal between the switch mechanism and the float, eliminating the need for a flexing bellows seal, packing gland or other failure prone sealing elements. When the liquid level falls, the float draws the magnetic sleeve below the magnetic field. The magnet swings out and re-actuates the switch to revert to the original position causing low level switch actuation .

...more

custom valve

All the items are manufactured as per customer specification of MOC, range and operating condition in as per Sigma’s standard design and engineering practice.

...more

Conductivity Level Switch

SIGMA's Conductivity Level Switches are simple, low cost and reliable instruments, for detection of conductive liquids. The Level Switch is available in single / multipoint level detection. A low alternating voltage is impressed between the active electrode(s) and the vessel wall / reference electrode. When the liquid comes in contact with the tip of the active electrode(s), an electrical path to ground is completed, closing the loop, resulting in flow of current. The current is transmitted to the control unit directly (in case of multiwire / integral design) or through a pre amplifier housed inside the probe head (in case of two wire design). The amplifier inside the control unit processes the signal and amplifies it to drive LED/ relay circuits

...more

Condensate Pot

CONDENSATE POTS are used to catch and hold condensate and foreign material. This helps keep manifold orifices clean and free of foreign material. They are located upstream of the instrument and have a bottom drain so that they may be cleaned. Installation can be either vertical or horizontal lines between primary (Flow Meter) and the secondary (transmitter/ gauge) to act as a barrier to the line fluid permitting direct sensing of the flow conditions. Units should be mounted at the same level minimizing possible error that could arise due to unequal head of fluid in the connecting pressure lines. SEAL POTS (sometimes called condensate pots) are used to allow a liquid seal between the instrument and flowing gases such as steam. Their function is to keep the liquid level constant in the impulse tubes. For example, in boiler liquid level applications the high pressure (HP) side of a differential pressure transmitter is connected to the vapor space on top of the steam drum. Steam condenses in the chamber or seal pot and fills the impulse line with condensate. The seal pot is located to allow the condensate to drain back to the source thus keeping the liquid level constant.

...more

Cable Float Switch

SIGMA's Cable Float Switch (Tilt Type) has a double chamber construction to make it absolutely hermetic. Switch differential is set with the help of a counter weight that can be adjusted alongside the cable of the switch. Its non-toxic body materials and mercury-free operated micro switch enable its use in drinking water applications.

...more

AUTOMATIC TANK LEVEL GAUGE

SIGMA’s AUGUST series Automatic Tank Gauges are designed to provide continuous liquid level measurement for bulk storage applications. The AUGUST is a float actuated instrument that provides continuous and reliable liquid level measurement, specifically engineered to reduce maintenance and enhance reliability.In principle, the AUGUST utilizes a large stainless steel float that is attached to a perforated stainless steel tape to detect the liquid level. The float traces the liquid level rise and fall due to the constant pull-back tension force provided by a power spring. The precisely perforated tape engages pins on a sprocket drive wheel that in turn drives the measurement counter mechanism. The float is guided between the guide wires that are kept straight/kink free through the tension devices. Alternatively, still wells that shall guide the float can be used where there is no provision for guide wires. This simple, rugged design makes the gauge to perform with negligible maintenance throughout its working life.

...more

ARMORED LEVEL GAUGE

SIGMA’s Flat Glass Level Gauges are reliable means for accurate measurement and direct observation of process fluids. These are designed to match industry requirements of ruggedness and material mix to widen the scope of application in process tank, pressure vessels and other containers with fluids varying from ordinary water to highly corrosive chemicals.THE SYSTEM: The Flat Gauges are inevitable means for process fluid measurement when it comes to severity of conditions. The medium to be measured iamber of the level gauge as that of the vessel and is viewed through a glass window. SIGMA Gauge Valves form a major component of the flat glass gauges. Two gauge valves at the ends of the gauge chamber are connected to the tank. Under normal operations, the valves are kept wide open causing the pressure to equalize in the system thus permitting the liquid to seek its true level for observation along the visible length. SIGMA offers Reflex and Transparent type Flat Level Gauges as required by the industry.

...moreBe first to Rate

Rate ThisOpening Hours