sleeve wrapping machine

Get Price Quote

Nido fully auto sleeve shrink machine designed for packing bottles with or without tray, the sealing machine can connect the production line & with its auto feeding film wrapping, sealing & cutting, shrinking & cooling; no need of an operator.

sleeve wrapping machine

300,000 - 1,000,000 Per Unit

Best Deals from Sleeve Wrapping Machine

sleeve wrapping machine

Get Price Quote

We are offering shrink wrapping machines. From now on, the size of the products is no more a limit thanks to UNIKA 50. Products of big and small dimensions ,and, most of all, of an unlimited length could be packed thanks to the exclusive independent sealing bar system, which overcomes the now old concept of “unique L-loom”.

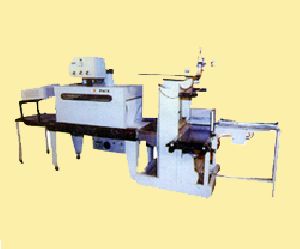

Fully Automatic Sleeve Wrapping Machine

Get Price Quote

We offer Fully Automatic Sleeve Wrapping Machine to our esteemed clients. The Fully Automatic Sleeve Wrapping Machine is ideal for big packs purpose of tins, bottles, cans etc. Automatic sleeve wrapping machine gives the clients a complete finger-free control. The photo valve controls the position and quantity of products which conveyed by heavy-duty conveyor. The heavy-duty cast steel Teflon covered sealing jags feature a retune height adjustment. Machine Features Fully automatic operationRigid StructureGood SpeedPLC ControlledMachine will have manual up & down arrangement Prerequisites Floor Space requirementApproximately 1 mtr from all sides of the machine. Hence clearance of 1 mtr should be added to the actual size of the machine i.e 4 mtrs x 2.2 mtrs x 3 mtrs height.Operator requirement1 Skilled operator, 1 semi � skilled operatorElectrical SupplyConnected load 2 KW, 415 ± 10%, 50 Hz ± 3% 3 Phase Earth & NeutralUtility3 Phase electric supply. 5HP Compressor, since the machine requires clean and dry air supply for pneumatic cylindersEssentialCaps should be properly seated on the bottleOperator should understand the working of the machine properly

Automatic Sleeve Shrink Wrap Machine

Get Price Quote

Automatic Sleeve Shrink Wrapping Machine" is distinguishable from other types of shrink wrapping equipment in that the two ends of the package have an opening (often called "bulls eyes") such as commonly seen for water bottle packaging where the openings can act a handles. In point of fact a sleeve wrapper is an excellent solution for bundling a wide variety of products and is often called a "bundler". Our Sleeve Wrappers are available in a wide range of size capabilities and configurations from manual feed to fully automatic with collating. Speeds generally decrease between cased product The Wraps manual two reel sleeve wrapping machine is the lowest cost method of producing a shrink wrap for transit purposes. The system consists of the FE sleeve wrapper and the M25.40T shrink tunnel. Each machine uses a 13 amp single phase electricity supply making it an extremely mobile wrapping solution. Shrink wrapping for transit purposes uses Polythene shrink film, the lowest cost shrink wrapping film available. One reel of film is mounted at a high level and the other is mounted at a low level. The two reels are joined by the sealing head, forming a curtain of film through which the product is pushed. The product to be wrapped is manually pushed through the curtain of film, enveloping the product. The sealing jaw is then brought down by hand, cutting and sealing the film producing a loose sleeve of film around the product. The next product to be wrapped then pushes the wrapped product into the heat shrink tunnel. In the tunnel the heat shrinks the film around the product leaving two open ends at the sides. The width of the film used compared to the width of the product determines how much of an open end is created. The Automatic Sleeve Shrink Wrapping Machine is suitable for products up to 550mm wide and 400mm high. Speed of operation is up to 400 products per hour. Additional features available with side feed sleeve wrap machines: Easy access and easy change of pusher - the pusher takes seconds to replace thanks to excellent access to the relevant part of the sleeve wrap machine. It’s also incredibly flexible; as many pusher plates as required are provided free of charge at the point of ordering Out-feed belt - the powered out-feed belt drives the pack automatically into the shrink tunnel, again useful for heavy or unstable collations. If it's an Automatic sleeve shrink wrapping machine that you need, then YPS can help. We supply a wide variety of sleeve sealers. We offer a range of high-speed sleeve wrappers aimed at the mineral water and soft drinks industry and specialist machines to wrap large items. Click start button below to view Video. All sleeve wrappers benefit from the following features: Fully safety guarded to exceed C.E. Marking regulations Heavy duty build quality to provide years of service Available in a variety of sealing sizes and in-feed arrangements Easy and intuitive to operate ‘Best in Class’, Heavy duty Teflon blade: this sealing system is more effective than a wire as it provides consistently strong seals and requires less maintenance than a three wire sealing system Pack clamp: fitted as standard on our sleeve wrap machines. This device clamps the pack securely in place while the film seals – absolutely critical for collation and unstable packs. Programmable pack counters to provide accurate shrink wrapping production and efficiency data, fitted as standard. All of our high speed sleeve wrappers offer the following benefits: High production speeds to reduce production time A heavy duty sealing blade for consistently strong seals Jaw / product safety device to protect the operator Perfect shrink tunnel air distribution for consistent, high quality results Automatic shrink film feed to both rolls for ease of use Automatic and manual cycle controls for convenience Programmable computer controlled memory for faster and effective operation Print registration options to enhance operations Variety of infeed arrangements for complete flexibility Heavy duty frame construction for years of continued use Side chains in the shrink tunnel for improved strength Sleeve wrap machines are more used in Mineral water manufacturing company Food industries like juice and jam making Pharma syrups bottle sleeve insertions Edilbe oil manufacturing companies And all pharma and non pharma companies

Semi Automatic Sleeve Wrapping Machine

Get Price Quote

Semi Automatic Sleeve Wrapping Machineis suitable for wrapping and then shrinking cylindrical like bottles, cans, boxes, big cartoon, bags, etc, with or without bottom tray. The whole process of sealing is mainly conducted in two steps:1) Wrapping the product frm top and bottom with the film.2) Shrinking the film around the product to pack it perfectly.Different sizes of specially ordered hrink wrappers are possible.

Automatic Sleeve Wrapping Machine

Get Price Quote

ADVANTAGES : * No use of bottom tray * No manual Interaction