Bopp Tape Slitting Machine

Get Price Quote

Thin Blade Slitter Scorer Machine

405,000 - 450,000 Per Piece

1 Piece (MOQ)

Best Deals from Slitter Machine

adhesive tape slitting machine

1,500,000 Per Set

Features : Full-automatic four-shaft turret, 2 shafts rotating at a time and 2 shafts steady for change over. Stepless speed regulation of frequency conversion and three-step length setting provide smooth rewinding operation to ensure accurate rewinding length. It can automatically decelerate and stall when operating at high speed. The unwinding is with Mag. Powder brake. The rewinding tension is adopted with the dual Mag. Powder clutch. The curved stretch roller is designed to eliminate tape wrinkling during extension and feeding. Staggered Trim Winding Auto labeling and slitting stationery tape functions.

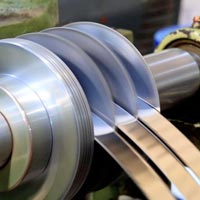

Slitting machine with coiler and decoiler

Get Price Quote

We Offer Metal Strip Slitting machine with auto. coiler and decoiler complete with electric control panel especially designed for Gold and Silver Strip Slitting.

Metal Sheet Slitting Machine

900,000 Per Piece

1 Piece(s) (MOQ)

Small Slitting Machine

Get Price Quote

We are indulged in providing to our customers with flawless quality Big and Small Slitting Machine. The products provided by us are manufactured using finest-grade raw material along with the up-to-date technology. Offered products are very famous amongst our patrons for their design and sturdiness. We are providing this whole collection in varied specifications as per patrons’ detailed demand. For Quotation kindly specified below things:- Strip Material Thickness Minimum and Maximum Width Minimum and Maximum Strip Coil weight Strip ID and OD Features: Reusable Highly durable Light in weight

Slitting Machine

Get Price Quote

machine meant for cutting different sizes of width upto 900mm &thickness of 1.5mm

Gang Slitter Machine

Get Price Quote

For slitting of tinplates into strips by rotary action of knives (cutters). Feeding is manual. Sheets one by one is to be placed on the feed table and to be pushed into the cutters with one side of the sheet all the time touching the side ledge which is preset at right angles to the cutter shafts.Cutters are mounted on specially designed holders which can slide on the cutter shaft to desired position. For firmly gripping to the cutter shafts, the holders are provided with gripper rings which can be tighted with screws provided for the purpose. The provision of gripper rings eliminates the screws coming in contact with the cutter shafts and thereby chances of damage to cutters is avoided. Precisely manufactured cutter shafts, holders and cutters permit quick change over for different strip widths.

High Speed Slitting Machine

Get Price Quote

Anti Vibration MS body Slitting Method Razor Blades or by Rotary Knives. Parent Roll Dia 800 mm Max. on 76 mm core I.D. Rewind – Central Drum or Duplex Type. Dynamically balanced drive rollers. Trim Separation by Air Blower of 1.0 hp AC motor. Line Speed upto 80-100 mtrs/min. Depending on type & thickness of substrate, material & operating conditions. AC drive controll pannel

Metal Slitting Machine

Get Price Quote

Our Metal Slitting Machine is designed using premium raw material and modern techniques in compliance with the standards of the industry. It is offered in varied specifications in order to meet the diverse requirements of patrons. Metal Slitting Machine has manual, semi, fully automated, and hydraulic pneumatic operations. It is suitable for light as well as heavy-duty applications. Also, Metal Slitting Machine can be fixed according to variable speed requirements.Specifications : Max coil width : Up to 2000mm max. Coil weight : Up to 25tons max. Coil thickness : Up to 8mm and more

Label Stock Slitting Machine

Get Price Quote

Features: Single phase power supply A.C. variable speed Slitting with doctor blade Electronic web guide

Optifoil Slitting Machines

Get Price Quote

Based on their extensive know-how in building rolling mills and their profound knowledge on the market, Achenbach enlarged their production range in 2006 by aluminium foil slitting machines, thus setting new standards. These machines comprise the following types:

Slitting Machine Drive System

Get Price Quote

We are engaged in manufacturing & supplying slitting machine drive system. With high speed slitting, these machines also offer inspection facility of various labels which are printed on packing materials. If a label is found missing, the machine automatically stops at the spicing table. With cost competency, these are useful for packing industries.

4 Bar Rotary Slitter Creaser Machine

Get Price Quote

Label Inspection Cum Slitting Machine

Get Price Quote

Optifoil Slitting / Separators Machine

Get Price Quote

To produce extremely thin foils down to 5 µm, two foils are doubled before they can be rolled in a final operating cycle. The Achenbach OPTIFOIL® separators AFS are complete machines for separating and possibly slitting the doubled foils after the final rolling process into strips. Typical performance figures of Achenbach OPTIFOIL® separators (AFS): > Max. foil widths 2150 mm > Foil gauge range 2 x 4.5 µm to 2 x 70 µm > Max. running speeds 1400 m/min > Max. unwind diameters 2100 mm > Max. rewind diameters 1200 mm Individual customer requirements are perfectly met by a number of design, automation and process modules.

Slitting Rewinding Machine

420,000 - 450,000 Per Piece

Mini Slitter and Rewinder Machine

Get Price Quote

Our Mini Slitter Rewinder is for the customers who have less working space and have minimal requirment of working width. Features: 24" and 36" Working Models Low Space Copact Design Twin Rewinding Shafts Details: Available from 24" to 36" Working. Four Set Of Male Female Rotary Shear Type Cutters for Slitting. Razor blade Cutting can be added.. Only Slitter and sheeter or Slitter and Rewinder available. Speed Changing panel 1 HP Three Phase electric Motor for Slitting Rewinding Tension Control through slipper Ring Free Mounted Rollers for Tension Control Web aligner Optional.

Gang Slitter Machines

Get Price Quote

We are one of the few names to offer supreme qualityGang Slitter Machine. The offered equipment is used for cutting sheets in different sizes. Fabricated using high-grade metals and alloys sourced from the reliable vendors, we ensure the premium quality of the products we offer. The provided hard chromed shafts help in the smooth operation of the machine offered.Features: Durability Reliability High performance Specifications: Model: Gsl 42 Capacity: 42" Motor: 1 HP Output: Depends on Operator

Paper Slitting Machine

Get Price Quote

This versatile unit provides flexible applications for vareity material, such as paper, foil, films, laminates materials. 2. Trolley unwind stand with shaft. 3. Circular knife & Razor Slitting system 4. Easy accessability to all operational systems at operators ease for reduced downtime and make ready. 5. Optional Auto tension control, Air expansion shafts, Safety chucks, Edge guiding system & Hydraulic material handling system at unwind. 6. Surface winding, pressure adjustable or centre winding with gap. 7. DC Variable speed drive. the main motor adopts DC variable speed regulating. 8. Unwinding adopts brake tension and automatic deviation-rectifying (DPC).

Slitter machine

225,000 Per Piece

Gang Slitter Machine

200,000 Per Piece

film slitting machine

Get Price Quote

Slitting Machine: WebFlex Machines is reputed as the best Slitting Machine manufacturers in India. We also export Standard Slitting Machines worldwide.

Bopp Tape Slitting Machine

525,000 - 550,000 Per Piece

Slitting Machine

Get Price Quote

Hyden is one of the leading designer and builder of a wide range of Slitting Machine, PVC Slitting and Laminate Slitting Machine. Find leading manufacturer of Laminate Slitting Machine, Slitting Machine and PVC Slitting Machine from www.hydenplastics.com We offer Slitting Machine, PVC Slitting Machine and Laminate Slitting Machine which are fully featured, efficient, affordable, accuracy & precision buildup. Our products are subject to high quality standards and are designed specifically for use in the flexible packaging and other related industries.

Coil Slitting Line Machines

Get Price Quote

micro slitter machine

Get Price Quote

Plasma treatment, which restores same Corona strength as required. Also cleans the substrate of dust. Safe capacitor possible because of PATTERN METALLIZING. Non-contact resistivity and free margin measuring system for very accurate metalizing to produce high quality technical metalized film. To safe guard the film from corrosion a thin layer of silicon is applied on the metallized film (protective covering). Individual Aluminum feeder motors & controls, which allows uniform deposition of metal.

bag slitting machine

Get Price Quote

Automatic cutting and emptying of all standard sacks, sack contents, sack sizes and sack types. Depending on machine size and sack, contents from 100 sacks hour up to 1200, The sacks to be emptied are fed by a conveyer belt to the sack emptying machine. The sacks fall through a cutting device where they are opened on each side.The open sacks slide into a rotating emptying drum where the sack contents are discharged. The sack contents fall into the product outlet and at the end of the drum the emptied sacks are transferred into a disposal housing which is attached to a empty sack disposal system. The empty bag disposal is then partially or fully automated.

SLITTING PRINTING MACHINES

Get Price Quote

SLITTING PRINTING MACHINES HIGH SPEED SLITTING MACHINE Anti Vibration MS body Slitting Method Razor Blades or by Rotary Knives. Parent Roll Dia 800 mm Max. on 76 mm core I.D. Rewind – Central Drum or Duplex Type. Dynamically balanced drive rollers. Trim Separation by Air Blower of 1.0 hp AC motor. Line Speed upto 80-100 mtrs/min. Depending on type & thickness of substrate, material & operating conditions. AC drive controll pannel

gang slitting machine

Get Price Quote

Gang slitting machine for cutting out body blank. Slitting of tin sheets into particular shape and size, simultaneously by assembled sheet in to strips, the main shaft are hard chromed fitted with 8 male female steel cutters, duly hardened and grinded, provided with rubber grippers molded, fitted with specially made heavy duty with motor starter and 'V' belts.