Slurry Seal

8,000 Per Set

1 Piece (MOQ)

type ssi-75 : mechanical seal ssi-75 series are semi cartridge slurry seal for special purpose single coil spring balanced seals designed for use in media containing abrasive or solid particles..

Mechanical Slurry Seals

Get Price Quote

We share glorious credentials with the famous Manufacturers, Suppliers and Exporters of Mechanical Slurry Seals from Maharashtra, India. Precisely fabricated using high-grade raw materials by our skilled engineers, our Slurry Seals are free from defects and conform to all industrial standards. We make available our Mechanical Slurry Seals in diverse specifications to address buyer’s demands. More about Mechanical Slurry Seals : These seals are specifically purposed for the fluids containing solid particles or with high viscosity, springs are also specially developed so that they will not get chocked up due to slurry powder. Combination faces with smooth lapping for no leakage, special elastomeric seal rings and “O” rings provides great support for the smooth running of seal for a long time. It is used for sewage plant, slurry, paper, pulp, sugar and effluents with solids.

Best Deals from Slurry Seal

Slurry Seals

Get Price Quote

Applications : Specially developed for steel plants on CRM (Cold Rolling Mill) in acid circulation pumps for PP, PVDF & PFA Lining Pump.Features : Slurry seal. Double seal for Non metallic pump. Standardized modular design. Inside Mounted

Slurry Mechanical Seals

Get Price Quote

We are offering a vast array of Slurry Mechanical Seals specially used for abrasive & media with solid particles. Sealing of abrasive media is a big challenge in process industries. Slurry Mechanical Seals are suitable for liquids containing 30-40% slurry. We provide Slurry Mechanical Seals with conical stuffing box and to be used as a replacement of double seal (back to back arrangement). These are specifically designed to thrive in the harshest abrasive slurry environments. Process fluids such as ores, limestone, phosphates, kaolin clay, drilling mud, lime mud, coarse coal, boiler fly ash, rock salt, sludge, sand and gravel are not at all a problem for these Slurry Mechanical Seals.

Multi Spring Slurry Pusher Seal

3,000 Per Piece

1 Piece (MOQ)

Double Slurry Cartridge Seal

Get Price Quote

Double Cartridge Seal Multi Spring Seal Metal Bellow Seal Application : Double Slurry Cartridge Seal is a factory assembled double Cartridge Mechanical Seal as cartridge unit specially design for slurry & viscous media. Also, this seal can be easily assembled in the equipment without need of any specific measurements. A self contained unit consisting of a Double seal assembly, mating ring, gland, sleeve, etc., which is pre-assembled and preset by the manufacturer prior to installation. Asuperior upgrade to component seals in both time saved and installation errors avoided.

Slurry Mechanical Seals

10,000 Per Piece

1 Piece (MOQ)

Slurry Non Metallic Pump Seal

Get Price Quote

Designed to handle abrasive particles up to 30% by weight. Specially designed Back plate of pump and Impeller in this particular seal type ZR32D which gives better seal life and performance. Hydraulically balanced faces for excellent seal reliability. Specially coated spring is located outside the process. Flushing helps to lubricate the seal faces from atmospheric side of mechanical seal. Features Slurry seal. Double seal for Non metallic pump. Standardized modular design. Inside Mounted. Materials Seal Ring Faces : SiC and Carbon Seat Faces :SiC and Ceramic Elastomer : Viton, TTV, FEP and FFKM MOC : SS 316, PVDF – CHANGE OF MOC ON REQUEST Operating Capabilities Shaft Dia. :20mm to 80mm Pressure : Full Vacuum to 8 bar Temperature : up to 180°C Speed: 3000 r.p.m. Applications Specially developed for steel plants on CRM (Cold Rolling Mill) in acid circulation pumps for PP, PVDF & PFA Lining Pump. What is Slurry Seal ? Slurry Seal For Non-Metallic Pump Seal Type ZR32/D IMS have been carefully designed and manufactured with great precision and care. Please Visit us to see our full range of Slurry Seal For Non-Metallic Pump Seal Type ZR32/D IMS to meet all your requirements. We are the manufacturer of Slurry Seal For Non-Metallic Pump Seal Type ZR32/D IMS in Mumbai INDIA.

Slurry Seal

Get Price Quote

Type VMH - 21 is a compact cartridgised balanced seal specially developed for handling slurries, sludges, thick syrups and polymerising fluids. In the cartridge construction the springs are isolated from the fluid enhancing the seal life. After detaching of the location plates provided, the seal can be easily installed straight away without setting measurements. Series 50B is a sturdy robust, seal capable of maintenance free runs for years together. Seal Characteristics Single Seal Balanced Independent on direction of rotation Cartridge Unit Application Pulp & Paper Slurry Pumps Sludge Pumps

Slurry Seals

Get Price Quote

Series AES-018 is a compact cartridgised balanced seal specially developed for handling slurries, sludges, thick syrups and polymerising fluids. In the cartridge construction the springs are isolated from the fluid enhancing the seal life. After detaching of the location plates provided, the seal can be easily installed straight away without setting measurements. Series AES-018 is a sturdy, robust, seal capable of maintenance free runs for years together. SEAL CHARACTERISTICS • Single Seal• Balanced• Independent on direction of rotation• Cartridge Unit APPLICATIONS • Pulp & Paper• Slurry pumps• Sludge pumps

Slurry Seal (LIE/703)

Get Price Quote

These seals are specifically purposed for the fluids containing solid particles or with high viscosity , springs are also specially developed so that they will not get chocked up due to slurry powder. Combination faces with smooth lapping for no leakage, special elastomeric seal rings and “O” rings provides great support for the smooth running of seal for a long time. It is used for sewage plant, slurry, paper, pulp, sugar and effluents with solids. Material Of Construction Sealing faces : Carbon, Silicon Carbide, Tungsten Carbide ,Ceramic Metal Part : S.S 304 , SS 316 , Hastelloy C , Alloy-20 Secondary Seal : PTFE , VITON

Slurry Seal

Get Price Quote

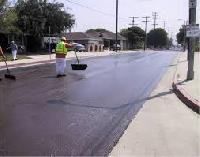

Slurry seals are a mixture of bitumen emulsion, graded aggregates, mineral filler, water and other additives. The mixture is made and placed on a continuous basis using a travel paver (Slurry Surfacing Machine). The travel paver meters the mix components in a predetermined order into a pug mill. The typical mixing order is aggregate followed by cement, water, the additive and the emulsion. The resulting slurry material is a free flowing composite material that is spread via a spreader box over the existing road surface. The consistency of the slurry material allows it to spread over the pavement, wetting it, and forming an adhesive bond to the pavement. The slurry mixture contains bitumen emulsion that breaks onto the pavement surface through heterogeneous or homogenous flocculation. The bitumen particles coalesce into films, creating a cohesive mixture. The mixture then cures, by loss of water, into a hardwearing, dense-graded asphaltaggregate mixture that is bonded to the existing pavement.

Slurry Seals

Get Price Quote

Multi Spring Slurry Seals

Get Price Quote

Multi Coil Cartridge Seals Multi Spring Slurry Seal is special purpose Multi coil cartridge balanced seal designed developed for handling slurries, sludges, thick syrups and polymerising fluids. The springs are isolated from the fluid being sealed by dynamic O-ring, which enhances the seal life. This compact design Multi Coil slurry seal permits to use in all types of centrifugal pumps. Application Paper industries. Petrochemicals. Petroleum refinery. Operating Limits Pressure : up to 15 Bars Temperature : (-)50 to 180°C Speed : up to 25 ms Sizes : 25 to 150mm

Slurry Seals

Get Price Quote

Slurry Seals, Thermosyphon Pot, Metal Below Seals, balance seal

Slurry Seal

Get Price Quote

We are considered as prime exporters of Slurry Seal in the country. Manufactured from high grade raw material, our Slurry Seal is specially designed for various solid contained liquids and slurry liquids. Besides, our Slurry Seal have Abrasive and Slurry applications. Attributes High performanceSubstitutable partsSpecially designed for Slurry servicesLoosely inserted Faces Available In Different Version Like Balanced Seal - LSOB - LSVBUn-Balanced Seal � LSO - LSV Operating Limits Diameter : 20 -100 mmPressure : 10 - 35 barTemperature : -45oC to +180oCSpeed : 25 m/s Used In Various Industries Like High Viscosity LiquidsSoapFoodDetergents

Slurry Seal

Get Price Quote

Slurry Seal, Cam Shaft, spring seal, Metal Bellow Seal, Multi Spring Seal

Cartridge Slurry Seal

Get Price Quote

Cartridge Slurry Seal, External Reverse Balanced seal, Without Bearing Seals

Single Spring Slurry Seal

Get Price Quote

Single Spring Slurry Seal, Wave Spring Seal, High Pressure Seals of Reactor

Slurry Seal

Get Price Quote

Slurry Seal