Heavy Duty Pressure Vessel

35,000 Per Piece

steel vessels

Get Price Quote

As we have a wide distribution network, we are able to ensure our payment procedures are fast and simple. Additionally, we are capable of providing prompt payment discounts. Our storage facility is capacious to maintain large stock. So, clients are free to approach us for urgent and massive requirements.

Best Deals from Spiral PP Chemical Reaction Vessel

Pressure Vessel

Get Price Quote

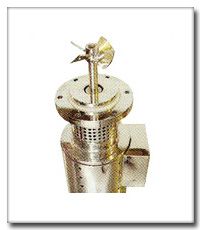

Pressure Vessel that we offer is well tested and therefore, is the perfect option on which buyers can easily rely. We are enlisted among the reputed Manufacturers and Suppliers of Pressure Vessel. We manufacture Pressure Vessel using high-grade basic material under the guidance of experts. We test the vessel on various quality parameters prior to its final dispatch. It can be obtained from us in small as well as bulk quantities. Highlights : Ideal in Injectable Section for Filling Sterile Products. Provided With, Inlet - Outlet Nozzle and Safety Valve. Joints are Argon Welded A Long Tube is Provided to Ensure Complete Drawing Out of the Fluid. Working Pressure of 3 Kg/cm. Square. For Air Tight Sealing Silicon "0" Ring is Used. Available Size - 5 Ltrs, 10 Ltrs, 20 Ltrs, 50 Ltfts, 100 & 200 Ltrs. Moc S S 304 / 316 / 316l • Cgmp Model with Documentation (iq, Dq Pq, 0q) as Option.

FRP Pentair Pressure Vessel

Get Price Quote

Pressure Vessel

Get Price Quote

• Ideal In Injectable Section For Filling Sterile Products. • Provided With Inlet - Outlet Nozzle And Safety Valve. • Joints Are Argon Welded. • A Long Tube Is Provided To Ensure Complete Drawing Out Of The Fluid. • Working Pressure of 3KG/CM.Square. • For Air Tight Sealing Silicon “O” Ring is Used..

rice vessels

Get Price Quote

Sterile Manufacturing Vessel

Get Price Quote

We are offering sterile manufacturing vessel. It is made as per who & us fda standards to manufacture sterile solutions. This is a completely closed vessel with agitator mounted on top dome. The vessel will be available with different accessories for different applications i.e. Standard stirrermagnetic stirrer as required by the customers.

Frp Pressure Vessel

Get Price Quote

We are offering frp pressure vessel. Pressure vessels are designed as per client’s requirement depending upon capacity required , temperature of fluids to be stored , type of fluid / density and pressure or vacuum expected in vessel. these vessels are manufactured normally with conical top and bottom or dish ends. pressure vessels are manufactured in various materials like pp + frp / pvc + frp / pvdf + frp / frp / frv etc.

Steam Jacketed Vessel

Get Price Quote

1 Piece(s) (MOQ)

We are offering steam jacketed vessel. Make solid and liquid preparations in bulk with equal ease. Extra heavy double walled stainless steel steam vessel perfectly designed. Low energy cost, high performance and without burning or scorching, most hygienically

PASTE PREPARATION VESSEL

Get Price Quote

Comes with 20 Ltrs to 250 Ltrs capacity. Basically this unit is used for preparation of starch paste. Hemispherical shape ensures that the heating of the starch paste is uniform and gets more surface area. The tilting type arrangement ensures ease in unloading the paste into any container or vessel. The starch is put in the kettle and water is added to it. The kettle is jacketed and is heated by steam/electrical till the starch melts and thick paste is achieved. The paste will be agitated with the help of an anchor type slow speed agitator which will constantly stir the paste so that there will not be any lumps formation and proper mixing is achieved. Mirror polished from inside and outside up to 240 Grit. Product temperature, measuring and controlling facility by means of TIC or PID control. Salient Features : cGMP Construction All contact parts of SS 316 grade Hemispherical bowl Bowl tilting by manual by worm and worm wheel Teflon scrapper for scrapping the paste Split, hinged top lid Excess pressure release valve on jacket for steam VFD for stirrer speed variation (Optional)

Vent Filter Vessel

4,855 Per Piece

High Pressure Vessels

Get Price Quote

We manufacture and supply High Pressure Vessels that can operate efficiently even when power supply is low. High grade materials are employed to ensure corrosion free and reliable products. Our vessels are amongst the best that are available and can be availed from us at affordable and reasonably nominal rates. They come with a compact design and perfect finish making them popular among our clients. Description: A pressure vessel is a closed container designed to hold gases or liquids at a pressure different from the ambient pressure Pressure vessels are used in a variety of applications in both industry and the private sector They appear in these sectors as industrial compressed air receivers and domestic hot water storage tanks Other examples of pressure vessels are: mining or oil refineries and petrochemical plants, nuclear reactor vessel, and storage vessels for liquefied gases such as ammonia, chlorine, propane, butane and LPG.

GRP REACTION VESSELS

Get Price Quote

POLY PLAST manufactures Process / Reaction Vessels of different sizes and shapes as per the customer's specifications, ranging from 200 ltrs, to 1, 00,000 Itrs capacity with conical, dished or flat bottom and top. The M. O. C depends on chemical, temperature and pressure conditions of the process requirement. We also supply these equipments with complete stirring assembly with Independent mounting structure and suitable sealing arrangements as per the customer's requirements. Stirrers are fabricated out of MS/SS materials, lined with plastic materials as per service warranted and tested with H.V.H.F spark testers for leak proof functioning. All thermoplastic liner weld joints are provided with non metallic conductive materials to facilitate spark testing. Similarly FRP lined metallic vessels are also tested with spark testing for pin hole or discontinuity of lining. These vessels are ideal replacement to the conventional MS glass - lined and Nobel metal claded vessels. POLY PLAST also provide cooling or heating coil made out of different materials as per the customer's requirement .

Large Volume Manufacturing Vessels

Get Price Quote

Optimizing the latest technology, we offer an assortment of superior quality LVP Manufacturing Tanks. These tanks are extensively used in pharmaceutical and other industries to process different kinds of materials. Precision engineered to meet industrial requirements, these tanks are available in various holding capacities to meet the varied needs of clients. In addition, these manufacturing tanks can also be customized according to the specifications sent by clients. Pay Mode Terms: L/C (Letter of Credit) Minimum Order Quantity: 1 Piece/Pieces Port of Dispatch: mumbai Production Capacity: 1/month Delivery Time: 6-8weeks

Liquid Manufacturing Vessel

Get Price Quote

Sugar Dissolving Vessel. Manufacturing Vessel. Holding Vessel. Online Sugar Syrup Pre Filter Vacuum System for Transfer of Sugar & Sugar Syrup Zero Holdup Filtration Unit. Inline Homogeniser. Inter connecting vessel Sugar Suction Pipeline

Silos AND Storage Vessel

Get Price Quote

The storage vessels that we manufacture are acknowledged for their rugged construction. These storage vessels are made of superior quality SS 304 that enhances their functionality. The vessels are used in distillery, beverages, food, chemical and pharmaceutical industries. Available in horizontal and vertical types, these products range from 100LTRS to 50000 LTRS. We also provide customization on our range of products as per the specification detailed by the clients. CAP:-100LTRS TO 50000 LTRSMOC:-MS,SS-304,SS-316,SS-316LSilosWe undertake Design, manufacture, Fabricate and supply of all Silos, Tanks & Vessels for Power & Process Industry.These are fabricated from superior quality material provides in them needed durability and finish standards. Available at competitively...CAP:-100LTRS TO 50000 LTRSMOC:-MS,SS-304,SS-316,SS-316L

High Pressure SS Vessel

48,000 Per Units

Pressure Vessels

Get Price Quote

PRESSURE VESSELS IN A WIDE RANGE CAPACITIES AND PRESSURES DC constructs stirred reactors and pressure vessels from most machinable alloys. Capacities range from 50 cc to 500 gallons (2 m3). Agitated reactor design pressures range from full vacuum to 150,000 psig (10,300 barg). Temperatures range from -400 °F to 2,500 °F ( -200 °C to 1,400 °C). Each stirred reactor is a complete system. This includes the reactor vessel, supporting stand, agitation assembly (magnetic stirrer, drive motor, belt, belt guard, impeller and digital tachometer), multiple process connections, drain, sample tube, temperature sensor, cooling coil and rupture disc assembly. Heating system and controls are optional. We offer a complete skid mounted stirred reactor system complete with product loading, feed, reaction and receiving modules, mass balance and product analysis. We also offer a variety of controls from simple manual controls to advanced PC-based SCADA and DCS. Please refer to our pilot plant section for additional information. Interested in a quote on a PDC stirred reactor? Please use our Stirred Reactor and Pressure Vessel Selection Guide to help you specify your stirred reactor or pressure vessel. INSTRUMENTATION AND CONTROLS PDC Machines supplies advanced instrumentation and control packages providing precise data acquisition to automatically record and manipulate multiple process parameters such as data logging, alarm monitoring, real-time and historical trending. These features are essential for predictable and repeatable process performance and scale-up. Our control packages are designed to be easily re-configured for flexibility and to adapt to developments in new technology. We combine the talents of process consultants, instrumentation and controls experts from various sources including Honeywell, Allen Bradley, Rosemont, Fisher, Siemens, Wonderware®, Intellution®, Cimplicity®, Think & Do®, LabVIEW®, and RSView® to name just a few. OUR CLIENTS Our clients include: • Air Products and Chemicals • Chevron Phillips Chemical Co • Akzo Nobel Chemicals • Celanese Chemicals • Bayer Corp • Cook Composites & Polymers • he Dow Chemical Co • E.I. Du Pont • Engelhard Corp • ExxonMobil Chemical Co • General Electric Corporate R&D • Omnova Solutions • International Specialty Products • Penford Products Co • Rohm & Haas • PQ Corp • Sartomar Co • Witco Chemical Corp. • Saudi Arabia Basic Industries (SABIC) • W.L. Gore & Associates

Spiral PP Chemical Reaction Vessel

Get Price Quote

1 Piece(s) (MOQ)

Storage Vessel

Get Price Quote

STORAGE VESSEL FOR PHARMA, OIL, COSMETIC & CHEMICAL INDUSTRY. Storage Volumetric Liquid Filling Machine For Pharma, Oils, Cosmetics & Chemical Industry: MOC of tank : SS 316 ,SS 316 L, SS 304 or MS as per customer requirement. Jacket provided as per customer requirement/optional. All pipes, pipe fittings and valves are of SS 316, internally electro polished, with tri-clover ended joints. Available in all capacities i.e. 10 to 5000 ltrs. As per customer requirement. Available in Horizontal & Vertical shape as per client requirement. Ensuring hygiene and maintaining a sterile environment, products in these storage tanks remain free from contamination. Volumetric Liquid Filling Machine is widely used in Pharma, oil, cosmetic & chemical industry.

Starch Paste Manufacturing Vessel

Get Price Quote

Starch Paste Kettle will be made out of S.S. 304 Rectangular Pipes and will be an independent resting type frame work where no foundation will be required. The Kettle will be a hemispherical type bowl with either steam / Oil / Water heating Jacket will be provided. The Kettle will be manufactured from 2.5 mm thick S.S. 304 Sheet and The Jacket will be of 2.5 mm Mild Steel (In case of steam Jacket the thickness will be 4 mm) There will be oil / water heated fitted at the back bottom side of the Kettle. The Kettle Will be having a worm type arrangement for tilting. A temperature controller & a temp Indicator will be provided for temp control & Indication. The Kettle will be Insulated with 50 Mm thick glass wool

FRP Reaction Vessel

Get Price Quote

TFM + FRP REACTION VESSEL USED BY SURFACTANT INDUSTRY FOR THE REPLACEMENT OF DUPLEX STEEL WITH M-PTFE. M-PTFE PROVIDES GOOD WELDAIBILITY WITH CORROSION RESISTANCE. POLYPLAST IS THE FIRST COMPANY IN INDIA TO MADE SUCH A BIG REACTION VESSEL IN M-PTFE. THE REACTION CONTENTS ARE PURGED WITH STEAM AT 150°C, THE ACTUAL WORKING TEMPERATURE IS CLOSE TO 110°C.

Homogeniser

Get Price Quote

Micron has designed and developed High Pressure Homogenisers for products like Milk, Flavoured Milk, Ice Cream Mix, Dahi, Lassi, Tomato Paste, Tomato puree, Juices, etc.The Homogeniser provides a smooth Texture & better viscosity to the products. In Milk it reduces the fat particle size which gives the Milk a new appearance. Apart from the Food processing industry, Micron has supplied High Pressure Homogenisers for various application likeChemicals, Pharmaceuticals, Paint, Wax and other related industries.The machines are available from capacities as low as 50 ltrs/Hr to 20000Ltrs/ Hr. The Higher capacity Homogenisers are available with Forced Lubrication & Hydraulic Pressure adjustment system. The compact design of the machine has a very low maintenance. The Specially Designed chamber helps to change the Plunger Packing from the front side, this means more life to Rubber parts that is reduced maintenance time and cost.

Pressure Vessels

Get Price Quote

Made out of 16 gauges AISI 316 complete with ring cover, wing nuts and neoprene gasket. Bent out-let nozzle will be fitted with S. S. Pipe to draw out all the fluid from the vessel. Inlet nozzle for allowing pressurized air. This vessels are tested at 4 bar pressure , conical in shape at top.

Perfume Mixing Vessel

Get Price Quote

We are offering perfume mixing vessel. Machine application : 1) perfume mixing 2) low viscous liquid mixing 3) non foaming liquid mixing 4) liquid mixing 5) oil mixing machine operationdescription : connect inlet of vessel from swastik’s perfume transfer system to fill liquid into the swastik’s perfume mixing vessel. Start the agitation for mixing the liquid. Stop the agitator after desired time. Connect outlet of swastik’s perfume mixing vessel to swastik’s perfume transfer system for transferring liquid from vessel to another vessel or sub tank or swastik’s semi auto 8 head rotary vacuumetric perfume filling machine line depending on your process. The vessel can be easily cleaned using the swastik’s mobile cip cleaning system & spray nozzle (optional features) machine features : 1) din type vessel inlet 2) 1" din type outlet valve 3) vent provided 4) extra connections provided in inlet 5) level indicator with glass tube 6) level scale in mm 7) matt finish on the outside 8) super mirror finish on the inside 9) height adjustable +- 25 mm 10) sampling valve provided 11) flameproof motor 12) lifting hook provided

Homogeniser

Get Price Quote

We would like to have a very outset permit us to introduce ourselves as one of the leading manufacturer and exporter for homogeniser in india.

PASTE PREPARATION VESSEL

Get Price Quote

Comes with 20 Ltrs to 250 Ltrs Capacity. This Unit is used for preparation of starch paste. Hemispherical shape ensures that the heating of the Starch paste is Uniform and gets more surface area. The tilting type arrangement ensure ease in unloading the paste into any container or vessel. The starch is put in the kettle and water is added to it. The kettle is jacketed and is heated by steam or electrical. Once the starch is melted, a thick paste is achieved. This paste will be agitated with the help of an anchor type slow speed agitator which will constantly stir the paste so that there will not be lumps formation and proper mixing is achieved. Mirror polished from inside and outside up to 240 Grit. Product temperature, measuring and controlling facility by means of TIC or PID control. Salient Features cGMP Construction All contact parts of SS 316 grade Hemispherical bowl Bowl tilting by manual by worm and worm wheel Teflon Scrapper for Scrapping the Paste Spit, hinged top lid Excess pressure release valve on jacket for steam VFD for stirrer speed variation (Optional)

Injectable Sterile Mfg. Vessel

Get Price Quote

CAPACITY : 20 to 10000 Ltrs. TECHNICAL SPECIFICATION: Complete vessel design as per ASME Code. Instrumentation & connections comply with BPE & EHEDG guideline. Vessel design & fittings / Stirrer are designed for CIP / SIP. OPERATION : Complete aseptic design with Magnetic mixer & high shear Magnetic emulsifier. Zero dead leg aseptic design Flush bottom outlet diaphragm valve with SIP able. Sampling valve zero dead leg type with CIP/SIP able. Volume monitoring by Load Cell. PH Sensor / Conductivity Sensor provided on demand for online check Product PH & Conductivity. ADVANTAGES : Free and clean working area around the charging port. Variable speed drive allows to control of mixing speed while batch preparation. Designed in accordance with cGMP requirements for CIP and SIP. Mixing head designed for vigorous mixing or low volume blending. Magnetically powered drive, NO SEALS / NO SHAFT thereby eliminating contamination. Easy removable of drive unit.

Pressure Vessels

Get Price Quote

Being a customer-oriented firm, we make available numerous modes of payment and assure them for confidentiality of transaction. Also, our payment modes are authorized. We have maintained our high standards in the market by delivering only high-quality products and this is done by using quality raw materials obtained.