spiral wound metallic gasket

60 Per Piece

100 Piece (MOQ)

Why Our Spiral Wound Metallic Gaskets: Adequate flexibility Can withstand high pressure Maintains a seal under variable and uneven loading Longer working life Winding Material (Hoop) Available In: Stainless Steel Monel Titanium Filler Material Available In: CAF Non asbestos jointing PTFE Flexible Graphite Ceramic

Spiral wound gaskets

Get Price Quote

Spiral Wound Gaskets are extremely popular and widely used. A spiral wound Gasket is manufactured by spirally winding a performed metal strip and a filler on the outer periphery of metal winding mandrels. The winding mandrel outside diameter forms the inner diameter of the Gasket sand superposed metal and non-metallic windings are continually wound until the required outer diameter is attained. This engineered product is tailor made to be compatible with the flange closure in which it is to be used. They can be used over the complete temperature range from cryogenic to approximately 2000º degrees Fahrenheit. This type Gasket can be used in all pressures from vacuum to the standard 2500 PSI flange ratings. They are more resilient than any other type of metallic Gasket with the exception of pressure sealing metal Gaskets and, as a consequence, can compensate for flange movement that may occur due to temperature gradients, variations of pressure and vibration. Types of Spiral Wound GasketType RBasic construction, inner and outer diameters are reinforced with several piles of metal without filler to give greater stability and better compression characteristics. Suitable for tongue and groove or male and female or grooved to flat face assemblies. Type RIRSolid inner metal ring acts as a compression stop and fills the annular space between flange bore and the inside diameter. Designed to prevent accumulation of solids, reduce turbulent flow of process fluids and minimize erosion of flange faces. Suitable for male and female pipe flanges. Type CGUtilizes an external ring which accurately centers Gasket on flange face: provides additional radial strength to prevent Gasket blowout and acts as a compression stop. A general purpose Gasket suitable for use with flat face and raised face flanges. Type CGISuitable for use with flat face and raised face flanges and specified for high pressure/temperature service or where corrosive or toxic media are present. Note on use of inner rings: ASME B16.20 which covers spiral wound Gaskets requires the use of solid metal inner rings in Pressure Class 900, nominal pipe sizes 24" and larger, Pressure Class 1500, nominal pipe sizes 12" and larger, Pressure Class 2500, nominal pipe sizes 4" and larger, All PTFE filled Gaskets Type HEType HE Gaskets are used for heat exchangers where pass bars may be required. The outer portion is of standard spiral wound construction, whereas the rib partition is normally of single or double jacketed Type, securely fastened to the I.D. of the spiral wound portion. Type HE-CGThis Type is identical to the Type HE, except that it is fitted with an outer guide ring. Type HE-CGI With Spiral Wound Outer RingThe Type HE-CGI is a variation of the Type CGI spiral wound Gasket, developed for use on heat exchanger TEMA type flange arrangements. In conjunction with an inner ring, the standard spiral wound construction also supports an outer wound steel nose, designed for the purpose of accurate Gasket location. It is also available with solid metal outer ring. Type CG-RJThis Type designates a specially sized CG Gasket to be used on standard ring joint flanges. The outer ring is dimensioned to cover the ring joint grooves and to prevent the spiral wound portion from entering the groove. This type of Gasket should be used only as a maintenance repair item. Type 625Type 625 spiral wound Gaskets are similar to Type R Gaskets, with a thickness of 0.0625". These Gaskets are widely used wherever space restrictions indicate the need for a wafer thin Gasket design capable of sealing high pressures. Type TThese Gaskets are used for boiler handhole and tube cap assemblies. They are available in round, oval, obround, square, pear and diamond shapes. Please note Type T Gaskets rely on internal pressure in the boiler to properly seat the Gasket. This means, when a hydrostatic test is performed on the Gasket, the pressure exerted against the plate will further compress the Gasket-and it is necessary to tighten each nut to compensate for the additional compression of the Gasket under load. Type M, MC & MCSThese Types are designed for boiler manhole cover assemblies. They are usually round, obround or oval shape, depending of course , upon the manhole plate configuration. Type MC Gaskets have pre-formed inner and/or outer rings made of spiral windings. This centering guide permits the Gasket to assume its correct position and to compensate for inequalities in plate contours and fillets in cold-pressed plates as well as to prevent shouldering and pinching caused by radial misplacement. Type MCS Gaskets are manufactured with a solid metal inner and/or outer ring which also prevents over compression of the Gasket in high pressure systems.

Best Deals from Spiral Wound Gasket

Spiral Wound Metallic Gaskets

Get Price Quote

The Superior Quality Spiral Wound Metallic Gaskets Manufactured By Us is Highly Demanded By the Clients Owing to Its Excellent Ability to Recover Under Variable Loads. Our Spiral Wound Metallic Gaskets are Skillfully Manufactured By Spirally Winding a Preformed Metal Strip and Filler On the Outer Periphery of Metal Winding Mandrels. Its Winding Mandrel Outside Diameter Forms the Inner Diameter of the Gasket and the Laminations are Continually Wound Until the Required Outer Diameter is Attained. We Offer These Spiral Wound Metallic Gaskets in Customized Thickness and Sizes as per the Client’s Requirements.

Spiral Wound Metallic Gaskets

Get Price Quote

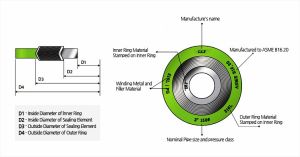

We offer Spiral Wound Metallic Gaskets. Champion Spiral Wound Gaskets are composed of a metallic continuous strip with a special shaped profile, coupled with a continuous filling strip (Asbestos, PTFE, Graphite etc.) evenly wound in concentric spiral under constant stress. The Spiral Wound Gaskets are reinforced on the inner and outer diameter by winding of several electrically welded metal. The main property of Spiral Wound Gasket, owing to elastic action of the special metallic strip profile, is that of offering a perfect sealing under fluctuating pressure and temperature conditions & maintaining tight elastic recovering. This elasticity can be modified by a proper selection of components. A proper selection of materials (both metal and fillers) allows the spiral gasket to accommodate the most varied operating conditions. Spiral Gaskets are made as per ASME B16.20 to suit ASME B16.5 flanges and as per "A" Series and "B" Series to suit ASME B16.47 flanges. We also make spiral as per DIN 2632-2638, IS Standards, etc.

Spiral Wound Metallic Gaskets

Get Price Quote

Our Spiral Wound Metallic Gaskets are skillfully manufactured by spirally winding a preformed metal strip and filler on the outer periphery of metal winding mandrels. Its winding mandrel outside diameter forms the inner diameter of the gasket and the hoop strip continually wounds until the required outer diameter is attained. We offer Spiral Wound Metallic Gaskets in standards as per ASME B 16.20 suitable for flanges of ANSI B 16.5 , MSSP 44 flanges for SORF , Tongue and Groove . We manufacture gaskets with Inner and Outer Ring with Partition Ribs for tube vessels, heat exchangers. These can be customized with standard and non-standard thickness and sizes upto 2000 mm Outer Diameter as per the client’s requirements.

spiral wound metallic gasket

22 - 2,550 Per Each

Spiral wound gaskets

Get Price Quote

We are engaged in manufacturing and supplying of spiral wound gaskets

Spiral wound gaskets

Get Price Quote

Spiral wound gaskets, Metallic Gaskets, industrial spiral gaskets

Spiral Wound Gasket

Get Price Quote

Spiral Wound Gasket, industrial gasket, Silicone Gasket, PTFE Gasket

Spiral Wound Gasket

Get Price Quote

Spiral Wound Gasket, PTFE Gasket

Spiral Wound Gasket

Get Price Quote

Spiral Wound Gasket, Gaskets