Spiral Wound Gasket

Get Price Quote

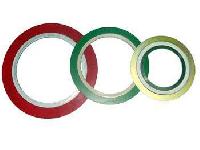

Spiral Wound Gasket of superior finish and quality are also manufactured by our company. These Spiral Wound Gaskets are made from crimped metal tape having sealing wraps out of asbestos or non asbestos gasket materials with inner and outer metal rings. These inner and outer metal rings are optional. Features Of Spiral Wound Gaskets : Different material combinations available according to the specifications of customers Filled with asbestos or graphoil or Teflon materials Can resist maximum pressure load Uses Of Spiral Wound Gasket : Used for duct flanges Also used for high temperature and high pressure flanges Can also used for pressure vessels Used in heat exchangers Used in fittings

Spiral Wound Gaskets

200 Per Piece

1 Piece(s) (MOQ)

To meet the demands of our clients, we are engaged in offering a wide range of Spiral Wound Gaskets. All these products are well known for the attributes like smooth functioning, high mechanical strength and optimum performance. These products are technically sound and ensure long lasting service life. We are offering these products at reasonable rates. Features Durable Anti-corrosive Scratch free

Best Deals from Spiral Wound Gasket

Spiral Wound Gasket

Get Price Quote

1000 Kilogram (MOQ)

Spiral Wound Metallic Gasket

60 Per Piece

100 Piece (MOQ)

Why Our Spiral Wound Metallic Gaskets: Adequate flexibility Can withstand high pressure Maintains a seal under variable and uneven loading Longer working life Winding Material (Hoop) Available In: Stainless Steel Monel Titanium Filler Material Available In: CAF Non asbestos jointing PTFE Flexible Graphite Ceramic

Spiral Wound Gasket

Get Price Quote

Spiral Wound Gaskets

Get Price Quote

Spiral wound gasket is manufactured by spirally winding a pre-formed metal strip and filler on the outer peripery of metal winding mandrels. The winding mandrel outside diameter forms the innner diameter of the gasket and the lamination are continually wound until the outer diameter is attaineds. the inner and outer diameters is reinforced with several plies of metal with no fillers being introduced. This gives greater stability and provides better compression and sealing characteristics. Then by varying the ratio of the filler to the metal plies for a given gasket width density, and hence the compressibilty, can be controlled. 1. Spiral wound gasket without inner and outer ring suitable for tongue and groove flange and narrow width flange. 2. Spiral wound gasket with outer ring which accurately centers gasket on flange and acts as compression stop. 3. Spiral wound gasket with inner and outer ring, innner ring gives an additional compression limiting stop and provides heat and corrosion barrier protecting gasket winding and flange erosion. 4. Spiral wound gasket with metal jacketed partition bar welded to spiral wound gasket for use on heat exchanger. available material metal winding strip:stainless steel type 304, 304l, 316, 316l, 321, 347, 410, inconel 600, monel, titanium, incoloy 800. filler material: compressed asbestos, flexible graphite, ptfe, ceramic. guide ring material: carbon steel, s.s. Type 304, 304l, 316, 316l, 321, 347, 410, inconel 600, monel, titanium, incoloy 800.

Spiral Wound Gasket

2 - 2,000 Per Piece

A piece of rubber or some other material that is used to make a tight seal between two parts that are joined together. Gaskets are normally made from a flat material, a sheet such as paper, rubber, silicone, metal, cork, felt, neoprene, nitrile, rubber, fiberglass, plastic polymer (polychlorotrifluoroethylene).

Spiral Wound Gaskets

25 - 2,250 Per Piece

10 Piece (MOQ)

Spiral Wound Gaskets

Get Price Quote

We are offering We are a prominent Spiral Wound Gaskets Manufacturer and Supplier in India. These Spiral Wound Gaskets have become the demand of industries because of their accurate dimension and high durability. The Spiral Wound Gasket is fitted into the ring made of the steel materials that are made of specific thickness. When the Spiral Wound Gasket is fitted into flange and the bolt is applied, the closure is ruled by the outer steel ring present in the gasket. For increasing the rating of the Spiral Wound Gasket a steel ring is added inside it. When the steel ring is applied the protection of the windings from impact and contamination is assured. Highlights Accurate dimensionHigh durabilityCorrosion resistanceWear-and-tear resistance

Bonnet Gaskets

Get Price Quote

Conventional Globe Valves Manufacturer in Mumbai may be used for isolation and choking services. Although these Globe Valves Manufacturer in India exhibit slightly higher pressure drops than straight valves but they may be used where the pressure drop through the valve is not a controlling.

Spiral Wound Gasket

Get Price Quote

Stainless Steel Spiral Wound Gaskets

10 Per Piece

1 Piece(s) (MOQ)

Hailing from Mumbai(India), the company is known for providing only quality products at reasonable prices. Automatic handling, storage, and distribution of the products become easy with our automated warehousing system. Also, our storage facility is timely upgraded to meet the changing market scenario.

Spiral Wound Gasket

Get Price Quote

AVAILABLE MATERIAL Metal Winding Strip: Stainless Steel Type 304, 304L, 316, 316L, 321, 347, 410, Inconel 600, Monel, Titanium, Incoloy 800. Filler Material: Compressed Asbestos, Flexible Graphite, PTFE, Ceramic. Guide Ring Material: Carbon Steel, S.S Type 304, 304L, 316, 316L, 321, 347, 410, Inconel 600, Monel, Titanium, Incoloy 800.

Spiral Wound Gaskets

Get Price Quote

Spiral wound gasket are special semi-metallic gaskets of great resilience. Therefore they are very suitable for applications featuring heavy operating conditions. Spiral wound gaskets are manufactured by spirally winding a V-shaped metal Strip and a strip of non-metallic filler material. The metal strip holds the filler providing the gasket with mechanical resitanence and resilience. Spiral wound gasket can be reinforeced by an outer centering ring And /or inner retaining ring.the outer centering ring controls the compression And holds the gasket centrally within the bold circle. The inner centering ring increase the Axial rigidity and resilience of the gasket.Spiral wound gasket should always be in contact with Flange and should not protrude into the pipe or project from the flanges. Spiral wound gasket can be used for sealing flange joints, manhole and handhold covers Tube covers, boilers, heat exchangers, pressure vessels,pumps, compressors and valves in industries Such as petrochemical, pharmaceutical,shipbuilding and food processing, in power industries And nuclear power stations. They are ideal for steam,oil,liquid,gases,acids,alkalines,various Organic medium sandsolvents.

Spiral Wound Metallic Gaskets

Get Price Quote

We offer Spiral Wound Metallic Gaskets. Champion Spiral Wound Gaskets are composed of a metallic continuous strip with a special shaped profile, coupled with a continuous filling strip (Asbestos, PTFE, Graphite etc.) evenly wound in concentric spiral under constant stress. The Spiral Wound Gaskets are reinforced on the inner and outer diameter by winding of several electrically welded metal. The main property of Spiral Wound Gasket, owing to elastic action of the special metallic strip profile, is that of offering a perfect sealing under fluctuating pressure and temperature conditions & maintaining tight elastic recovering. This elasticity can be modified by a proper selection of components. A proper selection of materials (both metal and fillers) allows the spiral gasket to accommodate the most varied operating conditions. Spiral Gaskets are made as per ASME B16.20 to suit ASME B16.5 flanges and as per "A" Series and "B" Series to suit ASME B16.47 flanges. We also make spiral as per DIN 2632-2638, IS Standards, etc.

Spiral Wound Gasket

Get Price Quote

Spiral wound gasket are special semi-metallic gaskets of great resilience. Therefore they are very suitable for applications featuring heavy operating conditions. Spiral wound gaskets are manufactured by spirally winding a V-shaped metal Strip and a strip of non-metallic filler material.

Spiral Wound Gaskets

Get Price Quote

Spiral Wound Gaskets are extremely popular and widely used. A spiral wound Gasket is manufactured by spirally winding a performed metal strip and a filler on the outer periphery of metal winding mandrels. The winding mandrel outside diameter forms the inner diameter of the Gasket sand superposed metal and non-metallic windings are continually wound until the required outer diameter is attained. This engineered product is tailor made to be compatible with the flange closure in which it is to be used. They can be used over the complete temperature range from cryogenic to approximately 2000º degrees Fahrenheit. This type Gasket can be used in all pressures from vacuum to the standard 2500 PSI flange ratings. They are more resilient than any other type of metallic Gasket with the exception of pressure sealing metal Gaskets and, as a consequence, can compensate for flange movement that may occur due to temperature gradients, variations of pressure and vibration. Types of Spiral Wound GasketType RBasic construction, inner and outer diameters are reinforced with several piles of metal without filler to give greater stability and better compression characteristics. Suitable for tongue and groove or male and female or grooved to flat face assemblies. Type RIRSolid inner metal ring acts as a compression stop and fills the annular space between flange bore and the inside diameter. Designed to prevent accumulation of solids, reduce turbulent flow of process fluids and minimize erosion of flange faces. Suitable for male and female pipe flanges. Type CGUtilizes an external ring which accurately centers Gasket on flange face: provides additional radial strength to prevent Gasket blowout and acts as a compression stop. A general purpose Gasket suitable for use with flat face and raised face flanges. Type CGISuitable for use with flat face and raised face flanges and specified for high pressure/temperature service or where corrosive or toxic media are present. Note on use of inner rings: ASME B16.20 which covers spiral wound Gaskets requires the use of solid metal inner rings in Pressure Class 900, nominal pipe sizes 24" and larger, Pressure Class 1500, nominal pipe sizes 12" and larger, Pressure Class 2500, nominal pipe sizes 4" and larger, All PTFE filled Gaskets Type HEType HE Gaskets are used for heat exchangers where pass bars may be required. The outer portion is of standard spiral wound construction, whereas the rib partition is normally of single or double jacketed Type, securely fastened to the I.D. of the spiral wound portion. Type HE-CGThis Type is identical to the Type HE, except that it is fitted with an outer guide ring. Type HE-CGI With Spiral Wound Outer RingThe Type HE-CGI is a variation of the Type CGI spiral wound Gasket, developed for use on heat exchanger TEMA type flange arrangements. In conjunction with an inner ring, the standard spiral wound construction also supports an outer wound steel nose, designed for the purpose of accurate Gasket location. It is also available with solid metal outer ring. Type CG-RJThis Type designates a specially sized CG Gasket to be used on standard ring joint flanges. The outer ring is dimensioned to cover the ring joint grooves and to prevent the spiral wound portion from entering the groove. This type of Gasket should be used only as a maintenance repair item. Type 625Type 625 spiral wound Gaskets are similar to Type R Gaskets, with a thickness of 0.0625". These Gaskets are widely used wherever space restrictions indicate the need for a wafer thin Gasket design capable of sealing high pressures. Type TThese Gaskets are used for boiler handhole and tube cap assemblies. They are available in round, oval, obround, square, pear and diamond shapes. Please note Type T Gaskets rely on internal pressure in the boiler to properly seat the Gasket. This means, when a hydrostatic test is performed on the Gasket, the pressure exerted against the plate will further compress the Gasket-and it is necessary to tighten each nut to compensate for the additional compression of the Gasket under load. Type M, MC & MCSThese Types are designed for boiler manhole cover assemblies. They are usually round, obround or oval shape, depending of course , upon the manhole plate configuration. Type MC Gaskets have pre-formed inner and/or outer rings made of spiral windings. This centering guide permits the Gasket to assume its correct position and to compensate for inequalities in plate contours and fillets in cold-pressed plates as well as to prevent shouldering and pinching caused by radial misplacement. Type MCS Gaskets are manufactured with a solid metal inner and/or outer ring which also prevents over compression of the Gasket in high pressure systems.

Bonnet Gaskets

Get Price Quote

As a standard, AIL Valves are made in Carbon Steel to ASTM A216 Gr. WCB. For valves in other materials and for accessories like gear operation and electrical actuators, suffix suitable abbreviations to the above ordering code such as : WC6 for ASTM A217 Gr. C6 WC9 for ASTM A217 Gr. WC9 LCB for ASTM A352 Gr. LCB LCC for ASTM A352 Gr. LCC C5 for ASTM A217 Gr. C5 C12 for ASTM A217 Gr. C12

Spiral Wound Metallic Gaskets

Get Price Quote

Spiral Wound Metallic Gaskets Rubber Gaskets are a precision machined low carbon steel gaskets which are then encapsulated in a casing of nitrile rubber. These Rubber gaskets have 3 main functions- Pressure testing used for minimal damage to flanges, Rubber contact points provide additional seals while protecting the flange facets. These are manufacture from high quality raw materials. These Rubber Gaskets are available in varied hardness and other physical parameters as per the client’s requirements. These are widely used in various industries and applications.

Spiral Wound Gaskets

Get Price Quote

We manufacture and supply best quality of Spiral wound gaskets which have proven themselves as highly effective sealing element for use in difficult, critical and arduous duties. Our Spiral wound gaskets are popular in various industries like Petrochemical, Chemical, Steam lines and Process Industries, where they have many advantages over older types of gaskets. We can manufacture Spiral Wound Gaskets with different filler like Graphite/Asbestos/PTFE/CAF etc. Also, we can provide different winding material.