Sponge Iron

4 Per Kilogram

50 Ton (MOQ)

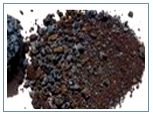

Our company is enlisted among the reputed Suppliers of Sponge Iron. The Sponge Iron we make available is used for the production of various steel and iron based products like bars, pipes and tubes. Courtesy our brilliant Logistics network, we are capable of delivering bulk orders of it within the promised timeframe. The entire range of the Sponge Iron is reasonably priced by us.

Sponge Iron

Get Price Quote

Sponge iron, also called as Direct Reduced Iron, is the product created when iron ore is reduced to metallic iron, usually with some kind of carbon (charcoal, etc), at temperatures below the melting point of iron. This results in a spongy mass, sometimes called a bloom, consisting of a mix of incandescent wrought iron and slag.It is a substitute for scrap and is mainly used in making steel through the secondary route.We are a leading Importer and supplier of high quality Gas Based Sponge Iron in India. Our high and consistent quality sponge iron facilitates steel makers to maintain high quality and reduce dependency on scrap.Sponge Iron or DRI (Direct Reduced Iron) is relatively uniform in composition, and virtually free from tramp elements. It has an associated energy value in the form of combined carbon, which has a tendency to increase furnace efficiency.

Best Deals from Sponge Iron

Sponge Iron

Get Price Quote

2 Metric Ton (MOQ)

coal based sponge iron

Get Price Quote

We are one of the leading traders of Coal Based Sponge Iron manufactured by various units in India. We have the infrastructure and cater the demand of Induction Furnace and Electric ARC Furnace. We have complete technical expertise of the product including its application/usage.

Sponge Iron

Get Price Quote

Reduced iron derives its name from the chemical change that iron ore undergoes when it is heated in a furnace at high temperatures in the presence of hydrocarbon-rich gases, carbon monoxide, or elemental carbon. Direct reduction refers to processes which reduce iron oxides to metallic iron at temperatures below the melting point of iron. The product of such solid state processes is called direct reduced iron. In the Direct Reduced Iron (DRI) plant, production of sponge iron is done using coal. This reduction process is done in a rotary kiln at temperature of around 850ᵒC-1050ᵒC.

Aisi310 Sponge Iron

Get Price Quote

Aisi 310 Which are Used Widely in Making Refractory Anchors and in Sponge Iron

Sponge Iron

Get Price Quote

Sponge Iron, Beams, Steel Angles, galvanized iron channels, H Beams

Sponge Iron

Get Price Quote

We deals in supplying of wide range of Sponge Iron.

Sponge Iron

Get Price Quote

Sponge Iron, Steel Rods, Black Soil

Sponge Iron

Get Price Quote

Sponge Iron, Steel Billets, Structural Steel, Stainless Steel Alloy

Sponge Iron

Get Price Quote

Sponge Iron, Ferro Alloys, Refractories, Steel Castings

Sponge Iron

Get Price Quote

Sponge Iron, Pig Iron, Steel Ingots, TMT Bars

Sponge Iron

Get Price Quote

Sponge Iron, nonferrous metals, metallurgical coal

Sponge Iron

Get Price Quote

Sponge Iron, copper millberry wire scrap, Bitumen Oil, Base Oil

Sponge Iron

Get Price Quote

Sponge Iron, iron scraps, Pig Iron, steel, Iron, metallic sponge iron

Sponge Iron

Get Price Quote

Sponge Iron, Mill Scale

Sponge Iron

Get Price Quote

Sponge Iron, Hydrous Kaolin, Ferro Chrome, Alumina, ores, Chromate

Sponge Iron

Get Price Quote

Sponge Iron, Coke, Iron Ore Fines, iron pellets, metallurgical coal

Sponge Iron

Get Price Quote

Sponge Iron, iron powder core, Iron Ores

Sponge Iron

Get Price Quote

Sponge Iron