Portable Suspension Type Spot Welder

Get Price Quote

Overhead suspension type transformers with portable spot welding guns are designed for high speed production to meet the needs of vast number of metal fabrication shops particularly for manufacture of automobile bodies and sub assemblies. Variety of guns viz. "C" type, Scissor type and Bell crank type with different throat depth and gap are available to suit simple or complex welding set up. The machine will be supplied with suitable Electronic Control depending upon the application.

Laser Spot Welding Machine

Get Price Quote

We make use of user-friendly interface that enables us to network and control the sorting, loading and unloading of all the finished products from a single location. By this, we make sure that the voluminous consignments are kept safely till the final send off. We are a notable name in the domain offering the best in class and quality CML-W 150 Laser Spot Welding Machine. Technology : The Principal of Laser welding machine for jewellery is thermal conduction, namely, the laser radiates the surface of the part, and the heat on the surface expands inside through heat conduction. By controlling parameters such as laser pulse width, energy, peak value and repeating frequency, the sample will melt, and thus forming specific molten pools. Due to its unique benefit, the product has been successfully applied to gold and silver jewellery processing, and welding of small-sized parts and porosity filling. Design : Personalized design for hassle free operation in compliance with ergonomics principles. Dependibility : Sturdy Frame Structure For lowest vibration makes it, ideal for factory use & trouble free operation. Display : New Touch Screen display for easy operation. Ease : Upto 10 memories cells for storing working parameters permanently. Big Inside chamber for easy movement of big samples. Advantages Fast, efficient, deep, quality welding. Welding points are free from pollution. Saves time & energy. Application for Jewellery Industry : Joining of different metals. Repairing of Precious Items with temperature sensitive area close to Diamonds & Gems stones. Assembling of jewellery parts. Holes and porosity filling. Antique repairing. Titanium spectacle frames repairing. Possible weld metals : silver, yellow and white gold, PT, Titanium.

Best Deals from Spot Welding Machines

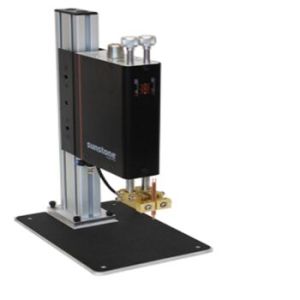

Bench Mounted Spot Welders

Get Price Quote

Press type air operated Spot Welders are designed for extra ordinary versatility and are available with different styles of welding head arrangements. These air operated welders are designed for high speed production work to meet the needs of a vast number of metal fabrication shops. Automatic feed mechanism with X-Y axis and Rotary movements with PLC could be supplied for fast production. A variety of electrodes and toolings can be fitted to render them suitable for spot welding, simple projection welding, electro-brazing, hot riveting, electro-forging and upsetting. Fully solid state electronic controls (Microprocessor based or CMOS based) are available for using with machine in order to obtain consistent and accurate weld results on a wide range of materials at a high speed automatic operation.These machines are designed and manufactured conforming to the Indian Standard Specification No.IS:4804 Part I and III or as per guidelines of JISC-9303 by a team of highly experienced engineers in welding technology.Specifications ; Standard Ratings : 25, 35, 50 and 75 KVA @ 50% duty cycle. Type: Air operated stationary press type Spot welders with pneumatic cylinder mounted directly. Construction: Robust construction, streamlined appearance with maximum resistance to deflection. Transformer enclosed in the main frame and pneumatic accessories mounted on the side of the machine and upper and lower arms mounted directly on to the body. Operating control station mounted on the machine clearly visible and within easy reach of the operator. Standard Throat Depths: 300, 450, 600, 750 and 900 mm (Machine with other throats also available on request). Welding Transformer: Transformer conforms to IS: 4804 Part-I and RWMA Standards, water cooled, class 'F' insulation with thermoswitch protection for overloading. Current Control: Welding current adjustable from 50 to 100% by means of a tap change links. Cooling System: Transformer, Electrode holders, welding electrodes are water cooled. Electrodes / Dies Toolings: One Pair of Morse Taper 2 straight Electrodes supplied as standard with the machine. Machine can be provided with custom-designed spot welding electrodes or welding dies to suit various sizes and shapes of work pieces, and suitable jigs and fixtures for holding, guiding and indexing of the work-piece as required at extra cost. Electrode Control System: Upper electrode actuated by a heavy duty 2-way cushioned pneumatic cylinder controlled by an electrically operated 4-way solenoid valve. Compressed air at 1.5 Kg/cm.sq. - 5.6 kg/cm.sq. (20 to 80 psi) acting on the pneumatic cylinder provides electrode force. Machine provided with air filter, air lubricator, air pressure regulating valve, air pressure gauge. High Lift Facility (Optional at Extra Cost): "High Lift" (retractable upper electrode) facility shall be provided by means of special cylinder. A hard/foot operated air valve causes the upper electrode to lift to the top most position for easy introduction of the job into the throat of the machine. Dual Pressure System (Optional at Extra Cost) : Dual pressure system shall be provided by means of two sets' of regulating and controlling devices and the necessary air circuits. Working in conjunction with special control units, this facility would enable application of a higher force on the job being welded at any point during the weld cycle. Controls: Appropriate Control will be incorporated with the machine as per requirement.

battery spot welder

Get Price Quote

special purpose side seam welding machines

Get Price Quote

special purpose side seam welding machines, can making machines

Spot Welder

Get Price Quote

Throat Depth (mm) 150 - 200 150 - 200 200 - 250 200 - 250 250 - 300 250 - 300 300 - 350 300 - 350, Models(KTS) 3 KVA 5 KVA 8 KVA 10 KVA 15 KVA 20 KVA 25 KVA 35 KVA Throat Depth (mm) 150 - 200 150 - 200 200 - 250 200 - 250 250 - 300 250 - 300 300 - 350 300 - 350 Throat clearance (TG) mm 150 200 250 250 300 300 350 350,Range of Welding Voltage 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V 8 steps Rotary Switch 2-6 V

spot cum projection welder

Get Price Quote

spot cum projection welder, press type spot welder, Projection Welder

Circular Seam Welding Machine

Get Price Quote

Circular Seam Welding Machine, 3 phase dc seam welding machine

Rocker Arm Type Spot Welders

Get Price Quote

Rocker Arm Type Spot Welders, Special Purpose 50KVA Multihead Spot Welders

Spot Welding Machine

Get Price Quote

Spot Welding Machine, electronic rectifiers

Spot Welding Machine

Get Price Quote

Spot Welding Machine, second hand garage equipment, Two Post Lift

JKARC SPOT Welding Machine

Get Price Quote

JKARC SPOT Welding Machine, electric car polisher, Two Stage Compressor

Spot Welding SPM

Get Price Quote

Spot Welding SPM

Pedal Operated Spot Welding Machines

Get Price Quote

Pedal Operated Spot Welding Machines

spot welding

Get Price Quote

spot welding, Electrical Transformer, Rectifier, Spot Welding Machine

Spot Welding Machine

Get Price Quote

Spot Welding Machine, Pillar Fly Press, Hydraulic Press Brake