Jewellery Spot Laser Welding Machine

400,000 Per Piece

1 Piece (MOQ)

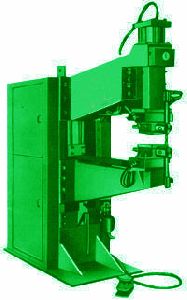

Spot Welding Machines For 20-200ltrs Barrel

Get Price Quote

1 Piece(s) (MOQ)

The rocker arm spot welding machine is an important machine in manufacturing Drums & Barrels. It is better to give some spots to the body sides before side seam welding operation. The machine can also be used for spot welding the handles etc.

Best Deals from Spot Welding Machines

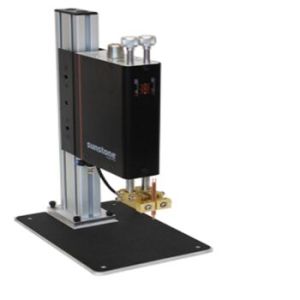

Digital Spot Welder

Get Price Quote

We make sure that the packaging of products is done using qualitative material in order to deliver the products safely. Only after complete inspection, we deliver the products in the dedicated time span. Based in Mumbai(India), we have gained wide appreciation owing to our high quality products and client-centric approach.

Seam Welding Machine

Get Price Quote

Our Seam Welding Machine is digitally programmed with thyristor control system, which helps it to give efficient perform in the varied industrial applications. Its robust construction and ability to give high performance have made it popular among clients. Salient Features Digital programmable thyristor controlModels from 30KVA to 300KVAHigh performanceSmooth functioning

MIG Spot Welding Machine

65,000 - 85,000 Per piece

1 Piece (MOQ)

Laser Spot Welding Machine

Get Price Quote

We make use of user-friendly interface that enables us to network and control the sorting, loading and unloading of all the finished products from a single location. By this, we make sure that the voluminous consignments are kept safely till the final send off. We are a notable name in the domain offering the best in class and quality CML-W 150 Laser Spot Welding Machine. Technology : The Principal of Laser welding machine for jewellery is thermal conduction, namely, the laser radiates the surface of the part, and the heat on the surface expands inside through heat conduction. By controlling parameters such as laser pulse width, energy, peak value and repeating frequency, the sample will melt, and thus forming specific molten pools. Due to its unique benefit, the product has been successfully applied to gold and silver jewellery processing, and welding of small-sized parts and porosity filling. Design : Personalized design for hassle free operation in compliance with ergonomics principles. Dependibility : Sturdy Frame Structure For lowest vibration makes it, ideal for factory use & trouble free operation. Display : New Touch Screen display for easy operation. Ease : Upto 10 memories cells for storing working parameters permanently. Big Inside chamber for easy movement of big samples. Advantages Fast, efficient, deep, quality welding. Welding points are free from pollution. Saves time & energy. Application for Jewellery Industry : Joining of different metals. Repairing of Precious Items with temperature sensitive area close to Diamonds & Gems stones. Assembling of jewellery parts. Holes and porosity filling. Antique repairing. Titanium spectacle frames repairing. Possible weld metals : silver, yellow and white gold, PT, Titanium.

Spot Welding Machine

Get Price Quote

APPLICATIONS - Spot Welding, electro-brazing, cross wire welding resistance heating and soldering. The machines are also capable of welding stainless steel, brass, phosphor, bronze, alloy steels, etc. Specific details can be sought on request.

Spot Welding Machine

Get Price Quote

We offer quality spot welding machine, which is fabricated using latest technology. Our spot welding machine is best suitable of welding all kinds of metals. We have gained huge appreciation for high performance and durability of spot welding machine in both domestic and international markets. We are reckoned as one of the leading manufacturers and exporters of spot welding machine. Salient features small heat effect areawelding spot can be adjustedelaborate and clear spottoo much after-procession is not neededaccurate orientationno damage to the jewelryhigh welding speed with high quality no pollution uses can weld all kind of metals

seam welding machines

Get Price Quote

- Transformer fitted inside the body and upper electrode arm mounted directly on to the body - Water Cooled welding transformer having core of high grade electrical steel, primary and secondary coils of solid electrolytic copper of ample section, heavy duty class 'F' insulated and vacuum impregnated, suitable to withstand continuous temperatures of 155oC - Current Control by transformer taps - welding current adjustable in 8 steps from 55 to 100% - Electrode control system - Upper ram actuated via a quick follow through device by a two-way pneumatic cylinder, controlled by a electrically operated solenoid valve. Compressed air at 15 to 110 psi acting on the pneumatic cylinder provides the necessary electrode force - Circular disc type Top and Bottom Welding Wheels electrodes - Variable Speed, reversible knurl / gear drive provided on top / bottom / both wheels as required. Drive power from a built-in 400 V, 3 Phase D.C. Motor, through variable speed reduction gearing to provide smooth and stepless variation of the welding speed - Thyristorized electronic control consisting of Sequence Timers such as Squeeze, Weld, Cool, Hold Heat control unit Application: - Suitable for seam welding a variety of materials including Mild Steel, Stainless Steel, Aluminium, Galvanized Steel, Tin Plate, Terne Plate, etc. - For all types of Drums, Barrels, Cans, Tins, Fuel Tanks, Mufflers, Utensils, Small Pipes, etc.

Body Maker

Get Price Quote

Mechelonic Engineers has now introduced the second generation, fully automatic container side seam welding machine with medium speed production. Machelonic engineers system of container welding is well established for producing continuous, constant narrow weld at optimum working speed, using copper wire as intermediate electrodes. ApplicationsThe machine is designed for medium speed automatic welding of tin sheets in container manufacturing. This machine has flexibility of design to accommodate different sizes of cans from 72 to 450mm length(body height) FeaturesThe machine is fully automatic combining various stages of manufacturing like destacker feeder, flexer, roll forming, overlapping the edges for welding of side seam, transport to welding station, wire drive, welding station, ejection of welding shells and wire collector. ConstructionCompact main frame of welded construction having streamlined appearance. The main transformer, variable speed drives, electronic control system etc. are enclosed in the frame and are easily accessible for serving. Main transformerSpecially designed class ‘F’ insulated transformer, water cooled and fully tropicalised for withstanding continuous operation. Destacker FeederPneumatically operated oscillating arm with a set of vacuum suckers, provided on the machine destacks the blanks and delivers them to flexer rollers. This process is monitored by electronic control system to give command for further operation. A hydraulically operated table is provided for stacking body blanks. This table automatically raises to adjust the level of body blanks for feeding to the flexer. The machine is provided with manetic sheet floaters and air jet separators to facilitate single sheet feed to flexer rollers. FlexerThe body blanks fed to flexing rollers are flexed and moved to roll former. Flexure is provided with rubber coated rollers to avoid damage to printed surface of tin sheet. Roll FormerThe flex banks are automatically moved into the roll former and rolled into desired shapes. Roll former has arrangement to adjust the body rolling diameter within specified range. Centering FlapsThe rolls blacks are collected by a set of pneumatically operated flaps, which also guides edges of rolled body in catch bar. A separate set of flaps are required for each range of body diameter. Crown AssemblyThe crown assembly near welding station controls exact diameter of body before welding. This assembly can be calibrated outside the machine on a setting mandrel. Calibrating Ringfor welding with narrow overlap (0.5mm), calibrating ring assembly provided on the machine will maintain parallel overlap.One set consisting of crown assembly, crown setting mandrel, centering flaps and calibrating ring will be provided with machine for a specific size of can as standard. Other sizes will be available on additional cost. Upper ArmThe upper arm is manufactured from special grade high tensile brass of suitable cross section to minimize any deflection during normal operation. The upper weld wheel and Z- bar are fixed to this arm. Arm is water cooled.Note: tooling for 301 and 302 at extra cost: Tooling for 301 and 307 together with a small arm could be supplied as aspecial case provided the customer uses Tin plates of Temper T3. Catch- Bar and Z-BarThe machine is provided with catch-bar and Z-bar to control overlap and also to guide the shell, while welding. Welding StationWelding station consists of two anti-fiction type weld wheels, made of special copper alloy with mercury contacts. These weld wheels are water cooled. A specially made weld wheel holder for lower weld wheel is provided. Welding pressure is provided by lower weld wheel. A single copper wire running over weld weld wheels act as intermediate electrode. The formed body of can is transported to welding station. The arrival of can is sensed through an electronic system and welding initiates and completes automatically. In this machine welding is at the bottom of can. Wire Flattening UnitA controlled drive with rollers, flatten the copper wire to the required flatness before entering the wire feeding system. Wire Feeding SystemAn accurate variable speed drive with electromagnetic clutch brake system and control wire tensioning devices provide positive and precise fed control of copper wire. Ejection of Welded ShellsWelding shells are received on a magnetic conveyor and ejected on the main conveyor. Wire controlling SystemThe copper wire used as the intermediate electrode for welding is wound on a re-coiler. Control PanelA centralizedcontrol panel is provided with facilities like operating switches, pilot lamps, ammeter, current fine setting, batch counter and continuous counter of cans. Machine is also provided with additional facilities like single cycle mode and setting up mode. Operating cycleLoad body blanks on the table, adjust parameters on the machine, operate the start switch. The machine instantaneously starts and continues to weld the body blanks. The operator has to only ensure that the destacker table has enough stock of body blanks. The automatic function includes picking up of the body blanks, flexing roll forming, guide to the catch- bar and then to Z-bar and welding at the welding station. The welded bodies are automatically ejected out. Safety FeaturesSafety features like No Wire Detector, Wire Cut-off Detector, No Can Detector, No Guard Detector Weld Wheel Position Detector are part of the machine. Side Stripping System The Machine can be provided with Nordson internal and external liquid lacker stripping system, alongwith take of conveyor and suitable cutting system at additional cost.

Spot Welding Robot

858,000 Per Piece

Spot Welder

Get Price Quote

In this method, a capacitor is used to store energy for quick release. Capacitor Discharge Spot Welder provides a large amount of weld energy with power adjustment. This process has many advantages over other welding types and ideal product for many spot welding application. As compared to other spot welder sparkweld’s Capacitor Discharge Spot Welder produces strong, clean and repeatable weld and also provide ample power for a large spectrum of the application at an affordable price. Weld formation takes place in milli seconds, in first few seconds it heats the weld area to eliminate surface contaminants and seat welding electrodes and then makes a higher energy weld which is secure and strong. Capacitor Discharge Spot Welder delivers repeatable welds during voltage fluctuation as weld energy is stored before use. Features: Weld process completed in milli seconds only. Up to 90 welds per minute. Easy to use and understand. The process removes surface inconsistencies and contaminants. Applications: Battery pack welding. Crosswire welding. Thermocouple welding. Honeycomb tacking: Honeycombs are used in compressor and turbine sealing. In this process, honeycomb is first welded and then joined by means of brazing. Many more resistive applications. Specification: Input supply:220v,AC,10Amp. Output:2500WS. KVA:5 KVA. Throat Depth:180MM. Throat Gap:200MM. Electrode Stroke:100MM. Dimensions in mm(WxHxL):810x490x1670. Weight:180KG.

Pneumatic Operated press weld type Spot Welding Machine

Get Price Quote

Most suitable for mass production due to pneumatic operation. Machine conforms to latest Indian and International Standards. Selection of correct weld time using solid state Electronic Timer ranging from 5-99-199 cycles. Quick current selection using Rotary Tap Switch "T" slotted face plate allows both vertical and horizontal adjustment of lower arm. Increased current carrying section because of special electrode holder system. Easy accessibility for maintences of Electronic, Electronic and Mechanical components. Rocker Arm type Spot Welder are designed and developed to meet the needs of a vast number of metal fabrication shop. Besides spot welding the machine can also be used for Electroblazing, cross wire welding and resistance heating. PNEUMATIC SYSTEM :The basic pneumatic system consists of a pneumatic double acting cylinder solenoid valve of 4 ways 5 port, filter, Lubricator, regulator gauge and foot operated initiating for solenoid coil.

Portable Suspension Type Spot Welder

Get Price Quote

Overhead suspension type transformers with portable spot welding guns are designed for high speed production to meet the needs of vast number of metal fabrication shops particularly for manufacture of automobile bodies and sub assemblies. Variety of guns viz. "C" type, Scissor type and Bell crank type with different throat depth and gap are available to suit simple or complex welding set up. The machine will be supplied with suitable Electronic Control depending upon the application.

Spot Welding Machine

Get Price Quote

We present premium spot welding machine, which is widely demanded in the market due to its high strength and superb quality. We are reckoned as a prominent spot welding machine manufacturer, exporter, and supplier from india. Our spot welding machine has set a bench mark in the drum manufacturing industries due to it unparalleled performance and cost effective prices. features : easy operation robust construction hassle free functioning tensile strength anti- corrosive maximum durability used for : spot welding of handles on top of the drums

Spot Welding Machine

Get Price Quote

We are renowned Manufacturer, Supplier and Exporter of Spot Welding Machine in Maharashtra, India. Robust construction, high performance, corrosion resistant parts are the highlights of our Spot Welding Machine. In addition, it is wear and tear resistant too. Buyers are free to place bulk order and we make sure that it is duly delivered. We are well equipped with in-house testing lab for quality assurance where the product is stringently tested many a times. Moreover, we offer the Welding Machine at market-leading prices.

pneumatic butt welding machine

95,000 Per Piece

Seam Welding Machine

Get Price Quote

APPLICATION :Spot welding, projection welding, cross wire welding, resistance heating, electro-brazing, With special attachments it is also possible to weld nonferrous material within certain limitions. USERS : Include - but are not limited to general engineering work-shop, makers of furniture, electrical instruments, containers, barrels and drums, telephone, radio communication devices, clocks, kitchen-ware,textiles machinery and spares automoblies-ancillaries,toys, air-conditions, refrigerators, motors, switchgear, etc. STANDARD FEATURES - ALL MACHINES :MAIN SUPPLY-415 Volts. Single Phase (2lines of 3 phase supply) 50 Hz. AIR OPERATION :Spring follow-double acting cylinder; Air line filter, lubricator, regular pressure gauge; Electric Solenoid Valve; Machine machanically capable of 125 operations/minute. ELECTRICAL - Foot Switch/Palm Button; Weld/No Weld Switch;Pressure Switch; Transformer in Class 'F' Insulation. provide with 8 current regulating taps between 55% and 100% output; Contrail circuits at less than 110 Volts. COLLING - By water with separate circuits for main Transformer, Secondary conductor and Electorder. die (in case of projection Welders) Thyristors. Each circuit to terminate in sight cup provide; wheel valves each circuit. PROTECTION - Transformer, Thyristors by themosate against water failure; Luminous overload indicator on panel. ELECTRONIC CONTROLS :Microprocessor based solid state Electronic Control with Thyristor Contact or unit.SPECIAL FEATURES AVAILABLE ON REQUEST : Actuation - Hydraulic-Motor H Air Reservoir h RTap Change Switch h Refrigerated or closed circuit cooling h Voltage/Current compensation h Other Voltages, Frequencies Special Purpose machines for /Special application, or Non Ferrous metals or Stainless and other exotic Steels electrodes h Special Tolong for projetion Welding Special Locating jigs for Spot /Switch Welding h Geneva Index \tablets h Automatic Feeders h Customer Ideas. We also manufacture :Arc, Butt and Seam Welding Machines; Salt Bath Furnace Transformer, Electronic Welder Controls, Electronic contractors etc.

Side Seam Welding Machine

Get Price Quote

The illustrated model is for side seaming to the full-length of the hollow drum and barrel body. Machine body is reinforced fabricated steel structure with a heavy duty transformer used as the main power source, for continuous welding operations. The machine is equipped with upper and lower weld wheel assembly, water cooling system and built in welding transformer.

battery spot welder

Get Price Quote