Polishing Pan

Get Price Quote

Strip De-Foiler Machine

140,000 - 225,000 Per Bag

Best Deals from Tablet Making Machine

Tablet Press Machine

Get Price Quote

MEDIUM SPEED TABLET PRESS

Get Price Quote

SE - Simple and easy, which is what it stands for. SE is a double rotary sturdy machine built on robust casted platform, body and center pillar. Turret drive through internal ring and pinion from gear box to turret ensures good control and free operation. Its compact design gives ergonomics and designs a new definition. It's HPPS (hydraulic power pressure system) with precise pressure dial gauge, hand lever and excess oil reservoir is one of the most effective systems of providing the sufficient pressure for desired thickness of the tablet. Salient Features: ELNP Turret and Upper cam tracks Force feeder (Aluminium alloy- hard anodized) Outside tablet parameter controls for tablet thickness and weight Unique press roll with sliding mechanism MHCOS:- Manual hydraulic compression overload system Auto lubrication Machine operation with Touch type HMI (Through PLC Optional Features: Gravity feeder Two way discharge chute with start up and shutdown rejection Three piece turret (Die plate - SS 316) Core Rod arrangement Swing arm with touch screen HMI CE certification. AHCOS (Auto hydraulic compression overload system) Double layer attachment (Gravity feeder) Anti Vibration mounts IQ, OQ, DQ documents

single punch tablet press

300,000 Per Units

1 Units (MOQ)

Tablet Dedusting Machine

Get Price Quote

Following the quality parameters, we are engaged in offering bulk of elevating de-burring machine the machines offered by usallows effective removal of burr & dust from tablets and come with charging height of 775 mm to 975 mm, discharging height of 775 mm to 975 mm, output (5 mm tablet) of 400000 tablets per hour. The system comes with adjustable speed support with precision designed tablet conveying route so as to provide for optimum performance support.

Rotary Tablet Press Machine

450,000 - 1,200,000 Per piece

1 piece (MOQ)

bakhoor tablet making machine

Get Price Quote

This machine is a hydraulic machine that putting the small particles or powder materials into the molds and pressing them into the tablets. This machine is special for pressing any dry powder into different shaped and different sized tablets. The machine can press dry powder into circle tablets, square, rectangle, ring, triangle, taper by changing moulds.

Tablet Coating Machine

Get Price Quote

Leveraging on or team of experts, we have manufactured Tablet Coating System that is used in various pharmaceutical industries. Automatic Tablet Coating System offered by us is fabricated using latest technological procedures. Designed for the purpose of coating granules, tablets and pallets, our Perforated Tablet Coating System is known for its high-precision and performance. In addition to this, we ensure availability of Perforated Tablet Coating System in different specifications and grades suiting to the preferences of clients. We are counted as one of the major Perforated Tablet Coating System Manufacturers from India. Attributes : Robust constructionHigh strengthResistant to corrosionLong functional lifeCompetitive pricing

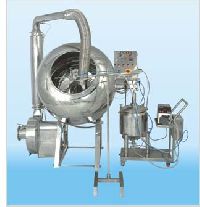

Polishing Pan

Get Price Quote

The Conventional Coating Pan is simple unit, which employs the principle of rolling a batch of tablets in an elliptical pan, spraying the coating solution on it and passing hot air across the tablet bed. An exhaust blower may be used to carry away the excess fumes generated during the coating and drying process. Gem manufacturer Conventional Coating Pan of various capacities ranging from 12” lab model to 72” conventional types.

tablet coating machines

Get Price Quote

Today many solid pharmaceutical dosage mediums are produced with coatings, either on the external surface of tablets, or on materials dispensed within gelatine capsules. Coating serves a number of purposes right from protecting stomach lining from aggressive drugs to protecting the tablet from stomach acids. It also helps in maintaining the shape of the tablet and thus can offer a delayed release of the medication. But for good results, a better coating medium is required. And the same can be fulfilled by Tablet coating spray nozzles.

Tablet Printing Machine

Get Price Quote

Salient Features high quality gravure prints at rates up to 60,000 (size 2) capsules per hour, or 80,000 depending on sthe diameter of the tablets designed for long runs at high speed total ease of handling one operator can run several machines

BACKLIGHT TABLET MAKING MACHINE SINGLE PUNCH PRESS

Get Price Quote

Tablet Making Machine Useful for making tablets upto 60 To 250 grams. Automatic compression and ejection device has been provided, actuated by revolution of the wheel drive. Feed and removal of tablets has also been made automatic. Eccentric pressure system has been applied for easy setting of thickness and hardness of tablets. A stainless steel hopper has been given. The unit has been mounted on a mild steel fabrication. Completed with one die and punch set made of chromium steel. Standard Equipments: The presses are supplied as complete units fitted with Die, Punch, Coating Pan, Fluid Bed Dryers, Oscillating Granulator, Packing Convertor Belt, Pump with Electric Motor, Pressure Gauge, Air Gauge, Limit Switch, Control Valve, Starter Oil tank(without oil), Micro switch, Roller Switch, Electric Panel Board etc.

tablet filling machine

500,000 Per Piece

single punch tablet press

110,000 Per Piece

Bakhoor Tableting Machine

Get Price Quote

Machine Operation Operator will manually spread powder over the die such that the cavity of the die is fully filled with powder evenly Now the operator will bring the punch (male die part) down with the help of the lever, there is a sensor to adjust Maximum down stroke. Once reached, this will compress & compact loose powder in the shape of the die. Now the Operator takes the punch up by lever to a level where the punch & cavity die are separated by at least 50 mm. Now the operator must bring the tray forward by pressing the forward button, after the tray is forward and directly underneath the cavity die, the operator once again bring down the punch head by lever such that the tablets fall Onto the tray. Once the tablets are onto the tray, the operator again brings the punch head up by lever and then Press tray reverse button so that tray comes out and then keep another in its place & repeat the process. Machine Applications Making Round Shape Bakhoor Tablets Making Heart Shape Bakhoor Tablets Making Star Shape Bakhoor Tablets Making Oval Shape Bakhoor Tablets Making Custom Shape Bakhoor Tablets

Polishing Pan

Get Price Quote

The process of coating tablets and confectioneries depends to a large extent on the personal skill of the coater. Some of the important factors which affect the process of coating are: Rotational speed, Angle of inclination of Pan, Volume and Temperature of hot air, and shape of pan. Coating Pans are incorporated with the above design features and are available in various sizes. Other geometrical shapes and angles can also be provided as per requirement. RPM of Pan can be kept fixed or adjusted by a vary pitch pulley or ac frequency unit. Hot air blower is provided to feed hot air at 40� to 80�C temp, controlled by a thermostat. Quantity of hot air can also be controlled by a damper. Polishing Pan with canvas lining available as optional with quick and easy mounting arrangement for mounting on to drive hub. Coating Pan have very heavy & sturdy structure , made from M.S. Structural material and covered from all sides. SPECIAL FEATURES Temperature controller provided for temp. controlling. Compact hot air blower with inlet air damping arrangement. Easy mounting arrangement for change over from Coating Pan to Polishing Pan.

Tablet Printing Machine

Get Price Quote

Feed disc and gravure rolls need to be changed to suit the shape and size of the product. Feed discs can be ordered with different numbers and sizes of pocket and can be interchanged in 5 minutes. Gravure rolls can also be ordered with any imprint and these are matched with the pocket spacing on the feed disc. Roll changing requires just one minute. Operation is completely automatic. After initial set-up, operator has to only replenish tablets or capsules and ink reservoir, when required. It automatically feeds, positions, meters, imprints and ejects. Operation is controlled by a toggle switch and a foot pedal.

Tablet Making Machine

Get Price Quote

Polishing Pan

Get Price Quote

Polishing Pan, Coating Pan, Mass Mixer, Multi Mill, tanks vessels