Welding Oscillator

Features: . Provides smooth, stable and precise oscillating movement of the welding torch. . Increases sidewall fusion, eliminates undercut. . Improves weld quality and appearance . . Independent dwell settings and speed settings for each side. . Compatible with PTA, GTAW, PAW, GMAW, FCAW and SAW weld processes.

...more

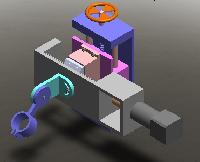

welding automation machines

We are offering welding automation machines. Metal welding is a fabrication process to join two metal pieces of same or different type by causing coalescence. Welding is generally done by melting the work pieces with heat & sometimes pressure, and introducing a filler metal to create a weld pool. After cooling, this weld pool becomes a strong joint.

...more

welding arc machines

TIG Welding Machine

Diode based power sources are the basic type arc welding power source used for MMATIG applications. Current control is achieved through saturable core reactor. Very reliable power source but not recommended for radiographic welding application as there is no dependable feedback for maintaining the output current constant due to fluctuation of input supply or change in load. Power factor is poor for these power sources.

...more

Submerged Arc Welding Machine

Submerged Arc Welding (SAW) is a common arc Welding process. It requires a continuously fed consumable solid or tubular (flux cored) electrode. Molten weld and the arc zone are protected from atmospheric contamination by being “submerged” under a blanket of granular fusible flux consisting of lime, silica, manganese oxide, calcium fluoride and other compounds. When molten, the flux becomes conductive and provides a current path between electrode and the job. The thick layer of flux completely covers the molten metal thus preventing spatter and sparks as well as suppressing the intense ultraviolet radiation and fumes that are a part of the SMAW process.

...more

Semi Automatic Gas Cutting Machine

Oxy fuel cutting or oxy fuel welding are processes that use fuel gases and oxygen to weld and cut metals respectively. Pure oxygen is used to increase the flame temperature to allow localized melting of the work piece material in a room environment. A common propaneair flame burns at about 2000 degree celsius, a propaneoxygen flame burns at about 2500 degree celsius and acetyleneoxygen burns at about 3500 degree celsius. In oxy-fuel cutting, a cutting torch is used to heat metal to kindling temperature. A stream of oxygen is then trained on the metal and metal burns in that oxygen and then flows out of the cut (kerf) as an oxide slag. Process requires gas cylinders for oxygen and acetylene, gas regulators, gas hoses, non-return valve, torch. This can cut only mild steel.

...more

Plasma Welding Machine

Plasma Arc Welding (PAW) is a modification of TIG(GTAW) Welding Process. As Plasma is an intense source of heat, it is used to fuse metals in this process and increase productivity. In PAW, as the electrode is placed within the body of the torch, plasma arc can be separated from the shielding gas. The plasma is then forced through a fine-bore copper nozzle, that compresses the arc and the plasma exits at very high velocity (approximately at the speed of sound) and a temperature approaching 28,000 °C (50,000 °F) or higher. Plasma is the temporary state of a gas.

...more

Miniature Based Machine

Cub series of miniature cnc profile cutting machines is targeted at small and medium scale industries. Portable cnc machines have almost all the features of a big cnc machine. Autocad drawings are converted into codes using the nesting software and transferred to the machine through pen drive. The machine cuts all shapes and parts as designed. An accuracy of 0.5mm may be expected from this machine of basic size of 1500mmx3000mm. It is possible to mount two torches of plasma or oxy-fuel within the cutting width of 1500mm. The length of the machine can be up to 6000mm. Cutting capacity will depend upon the capacity of plasma cutting machine. Most commonly used range is 1-30mm. However there is no limit up to 100mm.

...more

mag co2 welding machine

Gas Metal Arc Welding (GMAW), sometimes referred to by its subtypes Metal Inert Gas (MIG) Welding or Metal Active Gas(MAG) Welding, is a Welding process in which an electric arc is formed between a consumable wire electrode and the work piece metal, which heats the work piece metal, causing them to melt and join. Along with the wire electrode, a shielding gas is fed through the welding gun, which shields the process from the contaminants in the air. The process can be semi-automatic or automatic. A constant voltage, direct current, power source is most commonly used with GMAW, but constant current systems as well as alternating current can be used.

...more

gas profile cutting machine

Technocrats offer wide range of state of the art most user friendly CNC Profile Cutting Machines which are considered one of best option in market today. We have made a space for ourselves in a very short span of time as the leading manufacturers of Plasma CNC Profile Cutting Machines and exporter based in Mumbai in India. The features of our machines are developed based on the feedback received from survey & our users.

...more

Gantry Based Machine

Dual driven gantry type versatile cnc system for all your plate profile cutting needs. Rugged construction of panther makes it extremely suitable for plasma oxyfuel cutting with multiple cutting heads.

...more

Cnc Plasma Cutting Machines

The CNC Controlled Pipe Profile Cutting Machine provides wide working range from diameters 30mm to 1500mm and pipe lengths from 100mm to 12000mm using oxy fuel or plasma.

...more

cnc air plasma cutting machine

Technocrats offer wide range of state of the art most user friendly cnc cutting systems which are considered one of best option in market today. We have made a space for ourselves in a very short span of time as the leading manufacturers of plasma cnc profile cutting machines and exporter based in mumbai in india

...more

Welding Machine

Automation is a must for all industries today. Increasing competition calls for more and more automation in fabrication industries where metal cutting and welding is involved. There is hardly any application which is not possible to automate technically. The quality, speed, consistency and economy is possible only with automation. The basic building block for automation in industrial application is motion control. Addition of vision technology has widened the area of application.

...more

Automatic Girth Tank Welder

Welding system which enhances the productivity several times for welding of oil storage tanks, liners for reactor building of nuclear power stations. Submerged arc welding (saw) or gas metal arc welding (gmaw) processes are used. The operator sits comfortably in the cage and supervises the weld quality in situ. Flux, flux recovery system, wire spool etc. Are kept in the moving cage. Welding power source is kept on the ground. Welding power is supplied through welding cable to the welding head. The cage moves on the top edge of the circular plate with the help of special designed roller.

...more

Arc Welding Machine

MMA process use drooping characteristic power source and consumable electrodes which produces arc by scratching the electrode with the job forming a short circuit. It is only when the short circuit is broken, arc is formed and the main welding current starts flowing. Welding takes place as the electrode gets fused with the job under the cover of the slag. In case of TIG, arc starts between tungsten electrode (non-consumable) and the job under the cover of inert gas. Arc is started by scratching the tungsten electrode with the job or using a high frequency unit which initiates the arc between the tungsten electrode and the job.

...more

Air Plasma Cutting Machine

We are engaged in manufacturing and supplying of various types of air plasma cutting machine that are available at very nominal prices in the market.

...more

plasma air cutting machine

We are deal in various types of plasma air cutting machine that are available at market leading prices.

...more

Plasma Cutting Machine

GTAW Welding Machines

Thyristorised power sources have current feedback control which maintains the set output current constant. There can be many welding features such as up slope, down slope, pulsing, etc. Which can be incorporated in this type of power source. Efficiency and power factor of these machines are better than diode based machines.

...more

Portable Shape Cutting Machine

This is a semi-automatic shape cutting machine which cuts any shape as per the template. The templates are of magnetic steel. The magnetized stylus moves on the vertical surface of the template and cuts the shape as per the contour of the template. Its portable hence convenient to use in the yard, field etc. It requires single phase power supply of 230 volts.

...more

portable flame cutting machine

This is motorized portable flame cutting machine which moves on aluminium track of length. This can be also used for circle cutting by connecting to an attachment. Majority of flame cutting is done with this type of machine.

...moreBe first to Rate

Rate ThisOpening Hours