Welding Oscillator

We are offering welding oscillator.

welded h beam

H-beam welding system is an automatic system for welding H-beam. There are two different systems offered for this application. In one system job is moved. Welding is carried out by SAW or GMAW process. Sometimes twin wire or tandem welding process is used. In another system welding head is moved. H-beam is produced for structured requirements.

...more

Tig Welder

The reliable power saving Inverterised Welding Rectifiers. A quality product from the house of high technology. Specially designed to meet your welding requirements. The machines are built to work under the extreme industrial field conditions. All products are designed, manufactured & tested under one roof to ensure the quality.

...more

Submerged Arc Welding Machine-inverter Based

We are offering submerged arc welding machine-inverter based. Introduction submerged arc welding (saw) is so named because the weld and arc zone are submerged beneath a blanket of flux. The flux material becomes conductive when it is molten, creating a path for the current to pass between the electrode and the workpiece. The flux blanket prevents spatter and sparks, while shielding ultraviolet light and fumes that are normally a part of shielded metal arc welding. The flux usually is supplied to the welding head via a small hopper. A collection system gathers the excess flux for reuse. The process uses one or more continuously fed electrodes (wires) to maintain an arc. Saw is known for its ability to deposit large amounts of metal quickly, consistently, and safely. The basic saw equipment is a power source, control unit, wire unit, and nozzle.

...more

Submerged Arc Welding Machine

Submerged Arc Welding (SAW) is a common arc Welding process. It requires a continuously fed consumable solid or tubular (flux cored) electrode. Molten weld and the arc zone are protected from atmospheric contamination by being “submerged” under a blanket of granular fusible flux consisting of lime, silica, manganese oxide, calcium fluoride and other compounds. When molten, the flux becomes conductive and provides a current path between electrode and the job. The thick layer of flux completely covers the molten metal thus preventing spatter and sparks as well as suppressing the intense ultraviolet radiation and fumes that are a part of the SMAW process.

...more

Semi Automatic Pipe Cutting Machine

Oxy fuel cutting or oxy fuel welding are processes that use fuel gases and oxygen to weld and cut metals respectively. Pure oxygen is used to increase the flame temperature to allow localized melting of the work piece material in a room environment. A common propaneair flame burns at about 2000 degree Celsius, a propaneoxygen flame burns at about 2500 degree Celsius and acetyleneoxygen burns at about 3500 degree Celsius. In oxy-fuel cutting, a cutting torch is used to heat metal to kindling temperature. A stream of oxygen is then trained on the metal and metal burns in that oxygen and then flows out of the cut (kerf) as an oxide slag. Process requires Gas cylinders for oxygen and acetylene, gas regulators, gas hoses, non-return valve, torch. This can cut only mild steel.

...more

Submerged ARC Welding Machines

• Useful for applications requiring large amounts of strips to be cut. • Useful for applications requiring large amounts of strips to be cut. • Single torch can cut strips from 50 mm to 300 mm width and thickness up to 80 mm.

...more

Cnc Pipe Cutting Machine

• Highly productive and cost effective mode of cutting metal sheets and plates. • Cuts mild steel, stainless steel plates and aluminium sheets with high precision. • Integrate standard plasma, high speed and high performance plasma power sources based on customer’s business requirement. • High productivity and low operating costs

...more

Product CNC Gas Profile Cutting Machine

• Combines advantages of both gas cutting and plasma cutting. • Plasma cutting station can be used for high speed profile cutting of all metals and oxy fuel gas cutting station completes range of mild steel cutting.

...more

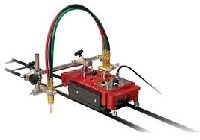

Portable Shape Cutting Machine - Mini-ostrich

We are offering portable shape cutting machine - mini-ostrich. Shape cutting machine also known as flame cutting machine or manual profile cutting machine. They are very useful for repetitive jobs, where they cut same profiles on a recurring basis. Template is cut on a thin sheet of mild steel or stainless steel. Then the template is mounted on the shapeflamemanual profile cutting machine. Tracer on the machine traces and guides the flame cutting torch to cut the mild steel plate put under the torch. Shapeflamemanual profile cutting machine has flexible arms, which can adjust the reach of the torch. It also contains beveling attachment. Mini - ostrich is a small portable radial arm oxygen cutting machine. Being small in size and light in weight, the machine can be easily carried to the worksite and placed directly on the plate to be cut. As the machine is mounted on four ball castors, it can be moved about on the plate as required.

...more

Portable Flame Cutting Machine - Oxy-1

We are offering portable flame cutting machine -> oxy-1. Special features: • straight line or circular cuts up to 300 mm thickness, depending on nozzle capacity. • bevel cuts up to 90 degrees. • internally asbestos lined body with fiber glass insulated circuit. • dynamically balanced armature for ultra smooth drive. • strong and solid construction for longer life. • precise control and proven performance. • straight line or circular cuts upto 180mm thickness.

...more

Plasma Welding Machine

Plasma Arc Welding (PAW) is a modification of TIG(GTAW) Welding Process. As Plasma is an intense source of heat, it is used to fuse metals in this process and increase productivity. In PAW, as the electrode is placed within the body of the torch, plasma arc can be separated from the shielding gas. The plasma is then forced through a fine-bore copper nozzle, that compresses the arc and the plasma exits at very high velocity (approximately at the speed of sound) and a temperature approaching 28,000 °C (50,000 °F) or higher. Plasma is the temporary state of a gas. The gas gets ionized after passage of electric current through it and it becomes a conductor of electricity. In ionized state atoms break into electrons(-) and ions(+) and the system contains a mixture of ions, electrons and highly excited atoms. This high velocity of atoms and heat melts the metal and helps to fuse two metals.

...more

Plasma Cutting Equipment

Plasma Cutting is process by which all types of conducting materials can be cut. This is an economic commonly used process for steel cutting in the industry today. Plasma arc is generated in a device called Plasma Torch. Compressed air, Argon, Nitrogen , Argon + Hydrogen ( 65%+35%) gas is used as plasma gas based on metals and quality requirements. Pilot arc is generated in the torch which oozes out of the nozzle and is thrown on to the job to be cut. Plasma arc is established between the cathode in the torch and the job which is anode through constricted hole in the nozzle. Plasma arc temperature is quite high ( in the range of 11000 degree C to 300000 degree C). The metal under cutting melts instantaneously and is thrown down by the kinetic energy of the Plasma arc. Electrical capacity of the power source decides the max. cutting capacity.

...more

MMA/TIG Welding Machine - TD Series

We are providing mma/tig welding machine - td series. Diode based power sources are the basic type arc welding power source used for mmatig applications. Current control is achieved through saturable core reactor. Very reliable power source but not recommended for radiographic welding application as there is no dependable feedback for maintaining the output current constant due to fluctuation of input supply or change in load. Power factor is poor for these power sources.

...more

Mig Mag Welding Machines

Gas Metal Arc Welding (GMAW), sometimes referred to by its subtypes Metal Inert Gas (MIG) Welding or Metal Active Gas(MAG) Welding, is a Welding process in which an electric arc is formed between a consumable wire electrode and the work piece metal, which heats the work piece metal, causing them to melt and join. Along with the wire electrode, a shielding gas is fed through the welding gun, which shields the process from the contaminants in the air. The process can be semi-automatic or automatic. A constant voltage, direct current, power source is most commonly used with GMAW, but constant current systems as well as alternating current can be used. There are four primary methods of metal transfer in GMAW, called globular, short circuiting, spray and pulsed spray each of which has distinct properties and corresponding advantages and limitations.

...more

Mig/mag Co2 Welding Machine-diode Based

Mig/mag co2 welding machine diode based continuously feed wire in the form of spool is used as electrode & the arc is shield under the cloud of insert gases such as argon, helium (mag) or mixture of active gases or most commonly used gas co2. features • 100% indian product. • most robust construction. • best suited for solid & flux coated wires, steel or aluminum. • solid state tropicalised pcb for increased reliability. • power transformer with delta to star connection for optimum ocv.

...more

micro plasma welding machines

In Micro Plasma Welding, a second nozzle is used in addition to shielding gas nozzle. Through this second nozzle, plasma flows, surrounding and constricting the arc, which leads to a high power density and stability. The surrounding gas protects the melt bath of oxidation. The advantages of plasma arc welding are: - higher welding speed and less distortion as well as a higher insensitivity regarding changes in distance. Due to the stabilizing effect of the plasma it is possible to work even with low currents. This makes micro plasma welding suitable for joining very thin metal sheets.

...more

gas profile cutting machine

CUMA machine of miniature CNC profile cutting machines is targeted at small and medium scale industries. Portable CNC machines have almost all the features of a big CNC machine. AutoCAD drawings are converted into codes using the nesting software and transferred to the machine through pen drive. The machine cuts all shapes and parts as designed. An accuracy of 0.5mm may be expected from this machine of basic size of 1500mmx3000mm. It is possible to mount two torches of Plasma or oxy-fuel within the cutting width of 1500mm. The length of the machine can be up to 6000mm. Cutting capacity will depend upon the capacity of Plasma cutting machine. Most commonly used range is 1-30mm. However there is no limit up to 100mm.

...more

gantry machine

Dual driven gantry type versatile CNC system for all your plate profile cutting needs. Rugged construction of Panther makes it extremely suitable for Plasma Oxyfuel cutting with multiple cutting heads. With precision and accuracy built into the design of the system, combined with excellent cut quality and productivity, Panther provides true value for money. Gantry based CNC profile cutting machines has all popular features generally found in the market. There is no limitation of width and length of the machine. It is possible to deliver machines with very high accuracy of cutting. Unique design of initial and auto height control makes the product more versatile and produces best quality of circles and other shapes. Beveling is possible even on circular cuts. Plasma cutting produces results which are so close to the ideal cuts produced by market leaders at much higher investment and operating cost.

...more

Flame Cutting Equipment

OXY-1 machine is popularly known as "Pug Cutting Machine". It is motorized portable flame cutting machine, which moves on aluminum track of 1.8 meters length. This can be also used for circle cutting by connecting to an attachment. Majority of Flame Cutting is done with this type of machine.

...more

electric welding machine

Metal Welding is a fabrication process to join two metal pieces of same or different type by causing coalescence. Welding is generally done by melting the work pieces with heat & sometimes pressure, and introducing a filler metal to create a weld pool. After cooling, this weld pool becomes a strong joint. Arc Welding is a type of welding that uses a welding power source to create an electric arc between the electrode and the base material to melt the metals at the welding point. They can use either Direct (DC) or Alternating current (AC) and consumable or non-consumable electrodes. The welding region is covered with some shielding gas or some slag.

...more

duplicating machine

Shape Cutting Machine also known as Flame Cutting Machine or Manual Profile Cutting Machine. They are very useful for repetitive jobs, where they cut same profiles on a recurring basis. Template is cut on a thin sheet of Mild Steel or Stainless Steel. Then the template is mounted on the shapeflamemanual profile cutting machine. Tracer on the machine traces and guides the flame cutting torch to cut the mild steel plate put under the torch. Shapeflamemanual profile cutting machine has flexible arms, which can adjust the reach of the torch. It also contains beveling attachment.

...more

dc welding machine

The machines are built to work under the extreme industrial field conditions. 100% Indian Product. Most advanced & tropicalised power source. Built-in High Frequency Electronic System without Spark Gap. Digital Ammeter & Voltmeter. ACDC selector. Remote control pendant. Protection against over heating, short circuiting and single phasing.

...more

dc tig welding machine

A quality product from the house of high technology. Specially designed to meet your welding requirements. The machines are built to work under the extreme industrial field conditions. Most advanced & tropicalised power source.

...moreBe first to Rate

Rate ThisOpening Hours