wound filters

They are designed for use with standard filter cartridges Various cartridge sizes and types are available such as diamond wound filter cartridges, pleated filter cartridges, activated filter cartridges, and ceramic and porous stainless steel cartridges Filter Housings can be designed and manufactured as per customer specifications in Carbon Steel or SS316 Filters can be provided in a twin assembly with changeover valves to ensure continuous filtration from one filter while the other is being cleaned or maintained Standard Cartridges are easily available and inter-replaceable Specialized Cartridges can also be manufactured on demand Cartridge filters are simple to clean and maintain locally Same filter housings can be used for different purposes by replacing the Cartridges

...more

Wedge wire basket

Wedge wire baskets manufactured with a 80 micron slot size are used as the primary filtering element Machine welding of the wedge wire basket ensures complete sealing and zero contamination of filtrate Filter elements are cleaned using Teflon brushes spring mounted on a central rotating shaft An adjustable timing arrangement can be used to automatically clean the filter elements Suspended solids can also be discharged periodically using an adjustable timer The filters can be manufactured in flow rates of 5 m³ hr to 50 m³ hr Miscella Filters reduce choking of downstream equipment e.g. heaters, by removing any solid particles and flakes from the Hexane-oil miscella They reduce the need for frequent cleaning of downstream equipment and the necessity of expensive plant shutdowns They also reduce loss of Hexane and can repay their costs in less than one operating season

...more

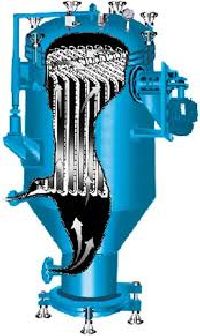

vertical pressure leaf filters

A Vertical Pressure Leaf Filter consists of a hermetically sealed tank with vertical filter leaves mounted on a central manifold at the bottom Each filter leaf is made from 5 layers of wire mesh – 2 outer filtering layers and 3 inner support layers Vertical Pressure Leaf Filters are used for filtration of liquids with ~7% suspended solids: A Vertical Pressure Leaf Filter consists of a hermetically sealed tank with vertical filter leaves mounted on a central manifold at the bottom Each filter leaf is made from 5 layers of wire mesh – 2 outer filtering layers and 3 inner support layers Outer layers of fine wire mesh are selected depending on the application - these act as the primary filtering elements and eliminate the need for filter cloth Inner layers of coarser mesh support the outer layers and serve to collect and discharge the filtrate Filter cake is discharged from the bottom of the filter using a pneumatic vibrator to shake the leaves Cake discharge outlet is provided with a Butterfly valve that can be pneumatically controlled from a remote location, or with a wedge lock full opening valve with heel leaf Vertical Pressure Leaf Filters are self cleaning and simple to operate without need for repeated opening of the filter body The entire filtration cycle can be easily automated by using a PLC to switch between the priming, filtration, and cleaning steps at regularly timed intervals or based on pressure readings inside the filter Applications Major application of Pressure Leaf Filters is in the filtration of Catalysts, Carbon black, and Bleaching earth in Edible oil processing, Crude oil Bleaching and Post-bleaching, Hydrogenation, Winterisation, and Fractionation Applications in the chemical and process industry include Aluminates, Fatty Acids, Sulphur, Mining, Brine, Resins, Ni Catalyst, and Electrolytes MOC Filtering Mesh is manufactured from SS316L, while the inner meshes and collecting channels of the leaves are manufactured from SS304 The housing and support elements can be manufactured from Carbon Steel, SS304, Monel, Inconel, Carbon Steel, etc. based on customer specifications Filters can be provided special linings such as SS304/ SS316L for food grade processes, e.g. in Vegetable Oil refining

...more

Solvent Oil Extraction

We provide customized filtration solutions for Solvent Oil Extraction plants including solutions for Miscella filtration, and subsequent filtration of Crude Oil, Lecithin etc. We are the preferred suppliers for leading Solvent Oil Extraction companies all over the country and our filters are being used in various solvent extraction processes including oil extraction from soya bean, sunflower and other oil seeds.

...more

Pressure Leaf Filters

Horizontal Pressure Leaf Filters can be designed with higher filtration areas as compared to Vertical Pressure Leaf Filters Horizontal Pressure Leaf Filters are especially used for de-waxing of vegetable oils, and similar processes

...more

Polypropylene Needle Felt

Polish Filters provide simple surface filtration for filtering suspended fine solids from liquids, and economically removing trace contaminants: Filter Bags are the primary filtering elements, supported by a Perforated Basket in a sealed Filter Housing Filter Housing and Support Baskets are constructed to provide a positive seal between the suspension and the filtrate, while enabling tool-less access and removal of the Bags for regular cleaning replacement Filters Bags can be provided in various pore sizes from 5 to 50 microns, based on the filtration requirement Filter Housings can be manufactured in various sizes, with single or multiple bags, as per customer requirements Filters can be provided in a twin assembly with changeover valves to ensure continuous filtration from one filter while the other is being cleaned or maintained

...more

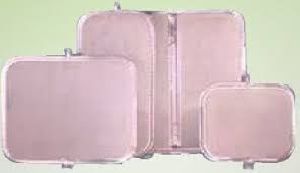

Polishing Filter

Polish Filters provide simple surface filtration for filtering suspended fine solids from liquids, and economically removing trace contaminants: Filter Bags are the primary filtering elements, supported by a Perforated Basket in a sealed Filter Housing Filter Housing and Support Baskets are constructed to provide a positive seal between the suspension and the filtrate, while enabling tool-less access and removal of the Bags for regular cleaning replacement Filters Bags can be provided in various pore sizes from 5 to 50 microns, based on the filtration requirement Filter Housings can be manufactured in various sizes, with single or multiple bags, as per customer requirements

...more

polish filters

Filter Bags are the primary filtering elements, supported by a Perforated Basket in a sealed Filter Housing Filter Housing and Support Baskets are constructed to provide a positive seal between the suspension and the filtrate, while enabling tool-less access and removal of the Bags for regular cleaning replacement Polish Filters provide simple surface filtration for filtering suspended fine solids from liquids, and economically removing trace contaminants: Filter Bags are the primary filtering elements, supported by a Perforated Basket in a sealed Filter Housing Filter Housing and Support Baskets are constructed to provide a positive seal between the suspension and the filtrate, while enabling tool-less access and removal of the Bags for regular cleaning / replacement Filters Bags can be provided in various pore sizes from 5 to 50 microns, based on the filtration requirement Filter Housings can be manufactured in various sizes, with single or multiple bags, as per customer requirements Filters can be provided in a twin assembly with changeover valves to ensure continuous filtration from one filter while the other is being cleaned or maintained Small pore sizes ensure complete removal of all solids and a clean final filtrate Polish Filters have a simple filtration process and are easy to operate and maintain Filter Bags can be easily and inexpensively exchanged Same filter housings can be used for different purposes by replacing the Filter Bags MOC Needle Felt or Woven Filter Bags can be manufactured in Polyester, Polyprolypene, Viscose, Nylon, or other special materials depending on the process conditions Support Baskets are manufactured in SS316/ SS304 as per customer specification, and can be provided in a fine mesh construction to act as a secondary strainer Filter Housings can be manufactured from Carbon Steel, SS304, or Carbon Steel with SS304 lining Applications Polish Filters can be used in Vegetable Oil refineries, Pharmaceuticals manufacturing, and in Chemical industries Primary use in Vegetable Oil refineries is for the final polishing of refined oil after de-odorization and before packaging Polish filters can also be used to filter bleached oil after the Pressure Leaf Filter, in order to remove trace contaminants before de-odorization

...more

miscella filters

Wedge wire baskets manufactured with a 80 micron slot size are used as the primary filtering element Machine welding of the wedge wire basket ensures complete sealing and zero contamination of filtrate Filter elements are cleaned using Teflon brushes spring mounted on a central rotating shaft Miscella Filters are used for filtering solid contaminants from Vegetable oil and Solvent mixtures: Wedge wire baskets manufactured with a 80 micron slot size are used as the primary filtering element Machine welding of the wedge wire basket ensures complete sealing and zero contamination of filtrate Filter elements are cleaned using Teflon brushes spring mounted on a central rotating shaft An adjustable timing arrangement can be used to automatically clean the filter elements Suspended solids can also be discharged periodically using an adjustable timer The filters can be manufactured in flow rates of 5 m³/ hr to 50 m³/ hr Miscella Filters reduce choking of downstream equipment e.g. heaters, by removing any solid particles and flakes from the Hexane-oil miscella They reduce the need for frequent cleaning of downstream equipment and the necessity of expensive plant shutdowns They also reduce loss of Hexane and can repay their costs in less than one operating season MOC Filter housing is fabricated from Carbon Steel or SS304, as per customer requirements Wedge wire baskets are manufactured from SS304 or SS316 wedge wires, which are especially imported from Europe

...more

lecithin filters

Filtering mesh manufactured from 60 80 wire mesh is used as the primary filtering element Filters can be provided with a steam injection system to clean the filtering element periodically Lecithin Filters are used to remove suspended solids and other impurities from crude Lecithin: Filtering mesh manufactured from 60 / 80 wire mesh is used as the primary filtering element Filters can be provided with a steam injection system to clean the filtering element periodically Filters can be provided in a twin assembly with changeover valves to ensure continuous filtration from one filter while the other is being cleaned or maintained Lecithin filters are easy to operate with a simple filtration process The filtering mesh can be easily replaced and refurbished locally Final quality of Lecithin is significantly improved after filtration, as compared to crude Lecithin The Filters are useful in both Vegetable Oil Refineries and also Solvent Extraction Plants that currently sell crude Lecithin MOC Filter housing is manufactured from SS304 or as per customer specifications Filtering mesh is manufactured from SS304/ SS316 The mesh is supported by a perforated sheet of SS304/ SS316

...more

leaf filters

A Horizontal Pressure Leaf Filter consists of a horizontal pressure tank with filter leaves mounted on a central outlet manifold A hydraulic jack is provided to open and retract the horizontal shell cover and or pull out the leaf assembly, thereby enabling easy access and manual cleaning of the filter leaves Fastening of the horizontal shell cover can be designed with a manual eye-bolt and nut arrangement or with an automatic quick acting Wedge Lock device

...more

Leaf Filter

A Vertical Pressure Leaf Filter consists of a hermetically sealed tank with vertical filter leaves mounted on a central manifold at the bottom Each filter leaf is made from 5 layers of wire mesh – 2 outer filtering layers and 3 inner support layers Outer layers of fine wire mesh are selected depending on the application - these act as the primary filtering elements and eliminate the need for filter cloth Inner layers of coarser mesh support the outer layers and serve to collect and discharge the filtrate Filter cake is discharged from the bottom of the filter using a pneumatic vibrator to shake the leaves Cake discharge outlet is provided with a Butterfly valve that can be pneumatically controlled from a remote location, or with a wedge lock full opening valve with heel leaf Vertical Pressure Leaf Filters are self cleaning and simple to operate without need for repeated opening of the filter body The entire filtration cycle can be easily automated by using a PLC to switch between the priming, filtration, and cleaning steps at regularly timed intervals or based on pressure readings inside the filter

...more

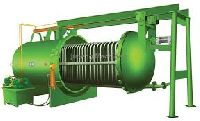

horizontal pressure leaf filters

Horizontal Pressure Leaf Filters are used in lieu of Vertical Filters, when the filter cake is sticky and difficult to clean automatically: A Horizontal Pressure Leaf Filter consists of a horizontal pressure tank with filter leaves mounted on a central outlet manifold A hydraulic jack is provided to open and retract the horizontal shell cover and / or pull out the leaf assembly, thereby enabling easy access and manual cleaning of the filter leaves Fastening of the horizontal shell cover can be designed with a manual eye-bolt and nut arrangement or with an automatic quick acting Wedge Lock device Horizontal Pressure Leaf Filters can be designed with higher filtration areas as compared to Vertical Pressure Leaf Filters Horizontal Pressure Leaf Filters are especially used for de-waxing of vegetable oils, and similar processes MOC Horizontal pressure leaf filters can be provided in the same design and material specifications as Vertical Pressure Leaf Filters, including Stainless Steel, Carbon Steel, and other materials Filters can be provided special linings such as SS304/ SS316L for food grade processes, e.g. in Vegetable Oil refining

...more

Horizontal Filter

Horizontal Pressure Leaf Filters are used in lieu of Vertical Filters, when the filter cake is sticky and difficult to clean automatically: A Horizontal Pressure Leaf Filter consists of a horizontal pressure tank with filter leaves mounted on a central outlet manifold A hydraulic jack is provided to open and retract the horizontal shell cover and or pull out the leaf assembly, thereby enabling easy access and manual cleaning of the filter leaves Fastening of the horizontal shell cover can be designed with a manual eye-bolt and nut arrangement or with an automatic quick acting Wedge Lock device Horizontal Pressure Leaf Filters can be designed with higher filtration areas as compared to Vertical Pressure Leaf Filters Horizontal Pressure Leaf Filters are especially used for de-waxing of vegetable oils, and similar processes

...more

Filter Accessories

We provide accessories, spares, maintenance, and refurbishing services for all Filters and Filter components including: Manufacturing and supply of new Filter Leaf sets for all sizes and models of Vertical and Horizontal Pressure Leaf Filters Stocking of spares for all Filters including Filter Bags, Pneumatic Vibrators, Valves, consumables, etc. for ready delivery Repair and refurbishing of Filter Housings, Filter Leafs, and other filter components

...more

Cartridge Filters

Cartridge Filters are used for filtering liquids with low to medium suspended solid content: They are designed for use with standard filter cartridges Various cartridge sizes and types are available such as diamond wound filter cartridges, pleated filter cartridges, activated filter cartridges, and ceramic and porous stainless steel cartridges Filter Housings can be designed and manufactured as per customer specifications in Carbon Steel or SS316 Filters can be provided in a twin assembly with changeover valves to ensure continuous filtration from one filter while the other is being cleaned or maintained Standard Cartridges are easily available and inter-replaceable Specialized Cartridges can also be manufactured on demand Cartridge filters are simple to clean and maintain locally Same filter housings can be used for different purposes by replacing the Cartridges

...more

Industrial Filters

We are well known for supplying of wide variety of Industrial Filters.

...more

Horizontal Pressure Leaf Filter

A Horizontal Pressure Leaf Filter consists of a horizontal pressure tank with filter leaves mounted on a central outlet manifold A hydraulic jack is provided to open and retract the horizontal shell cover and or pull out the leaf assembly, thereby enabling easy access and manual cleaning of the filter leaves

...more

Cartridge Filter

They are designed for use with standard filter cartridges Various cartridge sizes and types are available such as diamond wound filter cartridges, pleated filter cartridges, activated filter cartridges, and ceramic and porous stainless steel cartridges

...more

Filter Accessories Maintenance services

We provide accessories, spares, maintenance, and refurbishing services for all Filters and Filter components including: Manufacturing and supply of new Filter Leaf sets for all sizes and models of Vertical and Horizontal Pressure Leaf Filters Stocking of spares for all Filters including Filter Bags, Pneumatic Vibrators, Valves, consumables, etc. for ready delivery Repair and refurbishing of Filter Housings, Filter Leafs, and other filter components Benefits Regular maintenance increases the operational life of Filters Operational costs are reduced to lower breakdowns and wastage All our filters are specifically designed to be easy to maintain and repair, with easily replaceable components We stock all Filter components and accessories to enable quick turn-arounds and low plant downtimes

...moreBe first to Rate

Rate ThisOpening Hours