Hollow Spinning Machine

Get Price Quote

Cooling fans fitted for ambient air cooling. The machine is fitted with a vibratory arm motion and timers for the control of vibration, cooling, cycle time and speed, so a perfect distribution can be achieved throughout the moulding.

cotton carding machine

Get Price Quote

Best Deals from Textile Machine

Single Head Iron Wire Bind Machine

Get Price Quote

We are a chief Importer, Exporter & Supplier of Single Head Iron Wire Bind Machine. The Single Head Iron Wire Bind Machine offered by us is fabricated by experts using advanced technology and premium grade material. We procure Single Head Iron Wire Bind Machine from some of the most reputed vendors of the industry. Highly efficient, robust, sturdy and multifunctional Single Head Iron Wire Bind Machine can be availed from us in various specifications.

Toyota 810 E Shedding Loom

1,800,000 - 2,400,000 Per Piece

6 P (MOQ)

Hot Air Stenter Machine

265,000 Per Piece

1 Piece(s) (MOQ)

ropp cap printing machine

110,000 Per Piece

This four colour Offset Printing Machine is designed for high quality printing at a high speed, wet on wet. the machine is provided with two bearing brackets, between whch the printing cylinder and the machine is getting device are mounted. Though this the machine getting a stability which ensures, smooth and reliable operation. The inking devices can work together or separately. The machine can be adjusted for three, two or single colour printing. All the machine adjustment points are easily accessible and each printing unit can be set independently of the other. For fine register adjustment is provided with the plate rolls both exisly and radically. the individual rubber inking rolls are easily accessible detachable. The zinc plates are fixed firmly on both ends by means of retaining bars or rolls. The printing blanket is fixed securely at both ends to the printing cylinder and can be easily inserted. The turret hed spindle is indexed be Geneva mechanism which runs in oil bath the shafts of turret head run on antifriction bearings. All the shafts are grinding finish and run on Phosporous bronze bushes. The feeding and take out of caps are done manually.

Marzoli Rings

Get Price Quote

Maximum yarn quality in all working conditions High drafts up to 80 fold. Optimum spindle speed at every phase of bobbin build up thanks to an inverter drive. Independent spindles, ring rail and drafting system drives. Extremely reliable and fast doffing system with no trailing ends. Simple and reliable transport peg system for either bobbins or tubes. Ring frame stops to prevent production of defective yarn. Flexible linking alternatives.

Portable Lint Remover

50 Per Piece

100 Piece (MOQ)

air jet mill

9 - 40 Per 1

1 1 (MOQ)

AIR JET MILL - EMCO PSI 8 The Pharmaceutical jet mill utilizes compressed air to grinding system which rapidly expands to generate a high speed rotation of material which runs below sonic speed. This creates near sonic particle-on-particle collision, generating increasingly smaller particles. Centrifugal force holds larger particles in the grinding rotation area until they have achieved the desired fine particle size. Centripetal force drags the desired particles towards the static classifier where they are allowed to exit upon achieving the correct particle size.

Shinwoo Cocoon Bobbin Winding Machine

Get Price Quote

10 Set(s) (MOQ)

We are offering shinwoo cocoon bobbin winding machine. 1) model ss-7: in this machine both spindle have individual gear assembly. No need to stop the complete machine in case you need to do repairs of a single spindle. This machine is with new type of electrical scissor system.( old mechanical scissor option is also available at the same rate ) production per day for spun poly 602 is 8 kgs (depending on yarn quality & worker"s skill) production per day for 100d polyester is 4 kgs. (depending on yarn quality & worker"s skill) 2) new model 303a : in this machine single main gear drive both the spindles. Just like old casati models. Production is same as model ss-7.this machine is with new type of electrical scissor system. ( old mechanical scissor option is also available ) production per day for spun poly 602 is 8 kgs ( depending on yarn quality & worker"s skill ) production per day for 100d polyester is 4 kgs. ( depending on yarn quality & worker"s skill ) 3) model 202a : in this machine single main gear drive both the spindles. Just like old casati models. Production is same as model ss-7. This machine is with the old mechanical scissor option. Production per day for spun poly 602 is 8 kgs ( depending on yarn quality & worker"s skill ) production per day for 100d polyester is 4 kgs. ( depending on yarn quality & worker"s skill ) 3) optional wax device 4) optional oil device we have sold more than 3 50 such machines in india to various cocoon bobbin manufacturing companies in india. please feel free to contact us for more information.

Sulzer Weaving Machine Parts

485 Per Piece

Loom Textile Weaving Machine

Get Price Quote

Vacuum Ironing Table

23,650 Per Units

HYDROTESTERS

Get Price Quote

Hydrotesters for testing according to API, ASTM specifications. Single, double or triple head versions. Specific high productivity models for ERW products Specific high pressure testing models for API casing and tubing seamless products High productivity rotary version (max. 4” O.D.)

TEXTILE MACHINERY SPARE PARTS

Get Price Quote

We, being a quality centric company, offer product range that is strictly as per the globally accepted norms. Capitalizing on an efficient industrial network, our organization has made coalitions with numerous reputed logistics solution sources. Thus, we can ensure on time distribution of consignments. We can supply any kind of ‘Machined’ spares for textile as per sample. In case of Textile Industry.We can supply spares for following machines : Complete range of staple yarn spinning machines. Winding machines and twisting machines. Rapier and air jet looms. In the past we have exported abovementioned spares to USA, Argentina, Turkey, Thailand, Malaysia, Singapore, Nigeria and other countries.

ELECTRIC AUTOMATIC HAIRSTYLE TOOL HAIR BRAIDING MACHINE

490 Per Piece

Product DescriptionThe Gadget is a completely new hair styling tool that is very useful for twisting hair quickly and easily. In a few easy steps, create your own stylish curls, which can be held in place later on with jewelry or bands. With the Twist Secret, you are free to try out new ideas in styling: twist and curl all your hair or just a few locks and Let your imagination run wild!Features • You can compile the numerous pigtail, to participate in the activities you can save time, you can also put your dress more Beautiful.• You can also edit the ribbon on the inside of the machine with the hair,• The better prepared apron with a fixed object, you can make up your hair becomes beautiful.• Super adorable & Handy hair braider• Fancy Gift option for your GirlfriendHighlights: Brand: KawachiMaterial: ABS+PCBattery: 2 * AA Battery(not included)Including package weight: 450gHow to use the device1)Choose a lock of hair to curl and untangle it using a brush.2)Part the lock into two strands.3)Press the button to raise the tweezer(Fig.2). Place the end of one of the two locks under the tweezer and release the button so that the lock is held firmly by the tweezer. 4)Do exactly the same to fix the second lock under the other tweezer. 5)Line the device up with the length of the strands of hair(Fig.3). Hold the device slightly away from your head and stretch out the locks of hair. 6)Turn the device on to position 1. The tweezers rotate., twisting the locks(Fig.4). 7)Once the locks have been twisted and curled over their entire length, return the device to position 0. 8)Line up the device as described above. Turn the device on to position II. The device's head pivots, twisting the two strands of hair together(Fig.5).9)Once the twisting action is finished., return the device to position 0, and release the locks from the tweezers by pressing the push buttons. 10)Place an elastic band or else a attachment (sold separately)in the hair to hold the curl in place. 11)Repeat the operation for each new curl.

dyeing jigger machine

Get Price Quote

Dye Jiggers are your best buy, With latest technical improvements, ‘SHAKTI’ offers most sturdy, smooth and compact designed Jigger, which gives excellent performance under most economical conditions in the processing of light and heavy fabrics like cotton, rayon, silk or synthetics.

Tearing Strength Tester

Get Price Quote

Technical Specifications RISHIKESH tearing strength Tester Determines the Tearing Strength of fabrics, papers, plastic films or other similar materials is determined by measurement of the work done in tearing through a fixed length of the test specimen using of Elmendorf Tear Tester. The Elmendorf Tearing Strength Tester consist a brass sector pendulum pivoted on anti-friction ball bearings on a vertical bracket fixed on a rigid metallic base. The test specimen in shape of a rectangular piece held between two clamps, one of which is mounted on the pendulum and the other is mounted on the vertical bracket. The clamps are mounted in such a manner that their holding faces are aligned with each other when the pendulum is locked in its raised position. The pendulum is released by lifting a release lever. This action causes the test specimen to tear right through. The tearing strength is indicated on a scale fitted on the pendulum against a low friction pointer pivoted on the axis of the pendulum. An adjustable knife is also mounted on the bracket on which the pendulum and the fixed clamp is mounted. It is centered between the two clamps and is used for making the initial Cut in the test specimen. The apparatus is finished in metallic painting and bright chrome plating to give it corrosion resistant finish.Augmenting weights for increasing the range of the tester for testing high strength materials are available as optional accessories. Low strength materials can be tested by mounting multiple specimens at the same time.

Cocoon Bobbin Winder

Get Price Quote

2 Piece(s) (MOQ)

We are offering shinwoo make Cocoon Bobbin Winder. model 202a production 100d 4 kgs /24hrs model 303a production 100d 4 kgs / 24hrs model ss-7 production 100s 4 kgs / 24 hrs

Ultrasonic Fabric Cutting machine

Get Price Quote

Ultrasonic Fabric Cutting machine, fabric sealing machine

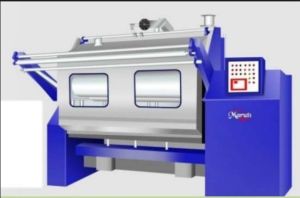

Side Loading Garment Textile Washing Machine

Get Price Quote

* Available in 5 to 90 kg. capacities.* Available in manual controlled, semi-automatic or programmable microprocessor controlled versions* Heating by steam or electric

Rotary Sheet Cutter

Get Price Quote

We offer Rotary Sheet Cutter. This machine is used for sharp and precise cutting of 2-ply corrugated liner as well as to cut Kraft or Duplex paper to the required length.

sewing thread winding machine

Get Price Quote

power jacquard machine

100,000 Per Piece

Yarn Dyeing Machine

Get Price Quote

HTHP Yarn Dyeing Machine is designed for dyeing of fibers yarns in production. Capacity of dyeing machine is calculated by the yarn to be dyed. The formula calculated i.e the receipe of the colour which is used to dye the different type of yarns, in Sample Dyeing Machine is used in this H. T. H. P. Yarn Dyeing Machines. H T H P Yarn Dyeing Machines are controlled by programmable controller The Dyeing Vessel available in market are in different forms like Vertical single vessel or Horizontal with no. of small tubes which vary according to the capacity of the yarn to be dyed.

High Speed Hank Reeling Machine

Get Price Quote

We offer high speed hank reeling machine. Construction of machine : solid angle frame construction collapsible type with aluminum section

yarn testing machines

Get Price Quote

yarn testing machines, Indenting Agents, Circular Knitting Machines

Foil fusing machine

Get Price Quote

A foil fuser can only apply flat foil and be used to "ThermoFuse" sheets with a toner image area. While a blind emboss effect can not be created, a foil embossed effect can be created with certain papers using a process called "ThermoEmbossing".

textile testing machine

Get Price Quote

textile testing machine, beam knotting machine, Embroidery machine

Needle Punching Machine

Get Price Quote

we have the following geotextile nonwoven line available; subject to prior sale. proposal no.1139113 1 hergeth card 2.5 meter width swift and breast each with 4 workers and 4 strippers, double doffer year 1992 2100 lbs per hour capacity fiber controls feeder model typ 99x96 1997 1 asselin profiling crosslapper series 658 2.5 meter input, 6.8 meter laydown 120 meters/ minute 1994 1 fehrer tacker needleloom nl 9, downstroke 60mm amplitude 2658 needles per linear meter 1325 strokes per minute 7.4 meter width 1994 1 fehrer 5 roll drafter 7.2 meter width 1994 1 fehrer needleloom nl 42, 7 meter width quad, 2 boards up & 2 boards down 70mm amplitude 9702 needles per linear meter 1100 strokes per minute year 1994 1 custom built accumulator counter weight type 7 meter width 80 foot capacity 1994 recorded line productio speed: 20 meters per minute running fabrics 3.8 to 18 oz per square yard location: usa price: ex mill floor usd 750,000.00