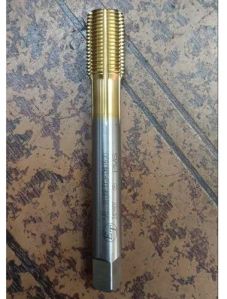

Machine Taps

Get Price Quote

We are a well-known Manufacturer and Supplier of qualitative range of Machine Taps. The Machine Taps, available with us, are best suited for high productivity runs. The Machine Taps are known for their accurate dimensions and rust resistance. The Machine Taps are widely demanded owing to their extensive industrial applications. Hss High Performance Taps Best suited for high productivity runs

HSS Threading Tap

300 Per Piece

1 Piece (MOQ)

Best Deals from Threading Tap

fluteless taps

Get Price Quote

MULTITAP ROLL FORM Universal The industry’s first general purpose high performance tap is also available in a full line of form taps featuring a new innovative geometric design, special base material and TiN coating. This allows one Multi TAP Form to handle numerous materials and applications at unsurpassed performance levels. Constructed of a proprietary grade of cobalt and TiN coated for exceptionally long life and versatility.

hss machine taps

Get Price Quote

We maintain a steady supply of our products courtesy an ultramodern inventory management system and a high-tech storage facility. Our resources enable us to maintain year round products' availability. The company has segregated its infrastructure into several units and one of them is packaging unit wherein we meticulously pack our products for ensuring safe and secure deliveries.

Threading Taps

Get Price Quote

We Are The Indian Manufacturer And Supplier Of Threading Taps As Per Below Specification Roughing Tap The Straps eight fluted made undersize to reduce the load on the finishing tap and particularly for difficult tapping operations. Recommended for use when tapping steels o close tolerance fits as required, reducing wear on the finishing tap. Finishing Tap Hand or machine tapping for through holes and blind holes where ample chip clearance is available. The lead chamfer permits easier starting and requires less tapping torque than bottoming taps. Bottoming Tap Used for tapping blind holes when maximum full form threads are required in minimum depth holes. Spiral Flute Tap Tap designed with spiral flutes in the same “hand” as the thread. This directs the swarf backwards out of the hole. Recommended for blind or deep hole applications in soft (eg. Aluminium) materials. Due to the suitability blind hole tapping the lead chamfer is normally that of a bottoming tap. Spiral Point Tap Designed primarily as a machine tap for tapping through holes. The Spiral Point is formed in the lead teeth at an angle to the tap axis. The swarf, due to the cutting action, is pushed forwards ahead of the tap. The flutes of the spiral point tap serve only to deliver coolant to the cutting edges, therefore much shallower flutes are used. Subsequently the tap has greater strength and makes precise tapping possible.

forming taps

500 Per Piece

Quarter Turn Elegant Washing Machine Tap

Get Price Quote

Roll Forming Tap

500 Per Piece

Roll Forming Tap

700 Per

2 Piece (MOQ)

Machine Taps MFP

Get Price Quote

High Performance HSS Threading Taps

Get Price Quote

Threading Taps

850 Per Piece

machine tap

Get Price Quote

OSG means accuracy and high precision rotating tools - Drills, End Mills and Taps in HSS and carbide materials ensuring optimal performance. Known for strong geometries and specially innovated racks and clearances with multi-layer coatings available in solid and through coolant types ensuring excellent performance. OSG have a special place in Aerospace and Auto Component where repeatability and productivity matters.

Threading Taps - 03

Get Price Quote

BA Thread Angle 47 1/2 0 Material : Special Tool SteelHardness : 58 to 620 HRC

forming taps

Get Price Quote

Forming Taps otherwise known as ‘Roll’, ‘Fluteless’ or Polygon taps. Used for the chipless production of threads in ductile materials such as copper, aluminium, soft brass or steel. Threads produced by fluteless taps are formed by plastic deformation, they are not cut. These taps do not have flute or cutting edges but have special roll forming lobes with circular land. They are operated at high speeds and are better at maintaining gauge qualification. Because they produce no chips they are very suitable for blind hole application as well as through hole application. Advantages Can be used in both blind holes & also in through holes Chips are pushed upwards due to spiral flute – Chip clogging avoided Full thread depth can be achieved and this design prevents tap breakage

Hand Taps and Short Machine Taps

Get Price Quote

Hand Taps and Short Machine Taps (Metric Coarse Pitch) Hand Taps and Short Machine Taps (Metric Fine Pitch) Hand Taps-B.S.W Form Hand Taps-B.S.F Form Hand Taps-U.N.C Form Hand Taps-U.N.F Form Hand Taps-BSCY Form Hand Taps-BS Conduit Form Hand Taps-BSP (Taper) Form RC Series Long Shank Machine Taps (Metric Coarse Pitch Threads) Long Shank Machine Taps (Metric Fine Pitch Threads) Nut Taps- Metric Coarse Pitch Threads Nut Taps-BSW Form Nut Taps-BSF Form Nut Taps-UNC Form Nut Taps-UNF Form

Threading Taps

Get Price Quote

Threading Taps, carbide cutting tool, cnc machine tool, Lathe Machine Tools

Threading Taps & Dies

Get Price Quote

Threading Taps & Dies, taper shank drill, carbide tipped drills

HSS Threading Tap

Get Price Quote

HSS Threading Tap, Adjustable Wrench, Ball Bearings, Blade

metric taps

Get Price Quote

metric taps, Tap Bolts, furniture bolt, flat bolt, C Channel / Z Braket