Current Transformers

15,000 Per Piece

Dry Type Ac & Dc Low Tension Power Transformer

Get Price Quote

1 Piece (MOQ)

Best Deals from Transformers

Medium Voltage Current Transformer

Get Price Quote

Power Transformers

Get Price Quote

Station & Multi-winding to suit specific needs & L.T. Transformers for generating Stations. Upto 10 MVA ,3 Phase , Upto 33Kv, ONAN / ONAF / OFAF /OFWF Cooling A power transformer characterized by inner and outer low voltage winding sections and a high voltage winding section disposed there between. The low voltage windings are comprised of a plurality of pancake coils, and the high voltage winding are comprised of a plurality of conductor strands spirally wound for a plurality of coil layers. The low and high voltage winding sections are laterally spaced with the low voltage windings disposed in side-by-side positions and adjacent to the high voltage windings. The high voltage windings having a smaller turn height than the low voltage windings and having conductor strands of smaller gauge than the pancake coils of the low voltage windings. A Power transformer is an electrical device that transfers energy between two or more circuits through electromagnetic induction.A varying current in the transformer's primary winding creates a varying magnetic flux in the core and a varying magnetic field impinging on the secondary winding. This varying magnetic field at the secondary induces a varying electromotive force (EMF) or voltage in the secondary winding. Making use of Faraday's Law in conjunction with high magnetic permeability core properties, transformers can thus be designed to efficiently change AC voltages from one voltage level to another within power networks. Transformers range in size from RF transformers less than a cubic centimeter in volume to units interconnecting the power grid weighing hundreds of tons. A wide range of transformer designs is encountered in electronic and electric power applications. Generation of electrical power in low voltage level is very much cost effective. Hence electrical power is generated in low voltage level.Theoretically, this low voltage level power can be transmitted to the receiving end. But if the voltage level of a power is increased, the electric current of the power is reduced which causes reduction in ohmic or I2R losses in the system, reduction in cross sectional area of the conductor i.e. reduction in capital cost of the system and it also improves the voltage regulation of the system. Because of these, low level power must be stepped up for efficient electrical power transmission. This is done by step up transformer at the sending side of the power system network. As this high voltage power may not be distributed to the consumers directly, this must be stepped down to the desired level at the receiving end with the help of step down transformer. These are the uses of electrical power transformer in the electrical power system.Two winding transformers are generally used where ratio between high voltage and low voltage is greater than 2. It is cost effective to use auto transformer where the ratio between high voltage and low voltage is less than 2. Again three phase single unit transformer is more cost effective than a bank of three single phase transformer unit in a three phase system. But still it is preferable to use than the later where power dealing is very large since such large size of three phase single unit power transformer may not be easily transported from manufacturer's place to work site.The high reliability of these transformers ensures maximum availability, lower maintenance costs and reduced life-cycle costs. Our ultimate goal is to exceed our customers' expectations continually by delivering the highest quality services. Power transformers comply with our quality policy by:Consistent management focus on quality;Continually improving the effectiveness of our Quality Management System;Understanding our customers goals and embracing them.

Furnace Transformers

Get Price Quote

A high current furnace transformer is provided by having the low-voltage windings arranged in a closed delta configuration within the transformer enclosure. Bus bar terminals are mounted exterior to the enclosure for providing electrical connection with the low-voltage windings. Furnace transformers are used to step down from voltages between 11 and 33 kV to levels of several hundred volts only. This results in massive secondary currents. As an example a 30 MVA unit at 150 V would result in a secondary current of 115 kilo Ampere. For these high secondary currents special bushings are required to connect to the bus-bars. These bushings are specified with very specific arrangements to suit the bus-bar arrangement and cooling system. Furnace bus-bars are mostly water cooled. Due to the high secondary currents and resistive losses the furnace layout is such as to limit the bus-bar length. The furnace transformers are then located close to the furnace itself and if they are single phase units, arranged in a triangle around the furnace. This means that there is a high risk of fire, a high ambient temperature and this whole set up is located at a level associated with the third story of the building. The location above ground level encourages single phase units due to the structural limitations of the buildings. To reduce the fire risk the transformers are contained in rooms, which adds to the high ambient temperature. Furnace transformers are very much in a production environment. Loading of these transformers is then very close to rated values and even beyond. This demands very reliable transformers. Shutdowns due to transformer problems are frowned upon. When shutdowns occur, the problem needs to be solved quickly. This in turn calls for good accessibility of the tap changer and other parts of the transformer. Large inspection covers in close proximity to the tap changer are often specified. Due to the nature of the process furnace transformers are specified with large tapping ranges. Thirty tap positions is not uncommon. Adding to the wide tapping range is the utilisation of the tap changer. Some users require up to 800 operations of the tap changer per day. This demands high maintainability and efforts to increase the maintenance intervals. On line tap changer oil filters are thus essential. To reduce downtime further, plug-in type diverters are specified. This allows a quick changeover of the diverter switch and an overhaul in a workshop environment with more time at hand. Another aspect of the process is the large number of short circuits that these transformers are subjected to every day. Transformers associated with open arc furnaces can be subjected to a number of short circuits per melt as the material being melted collapses across the electrodes. Bus-bar flash overs are also a fact of life on most furnace installations. To add to this peril, furnace transformers are required to have a lower than normal impedance. This gives rise to higher over-current factors. very robust design in terms of the transformers’ ability to withstand the dynamic effects of repeated short circuits is required. Minimum impedance values for furnace transformers of the core type are in the order of 4 – 5 %. To achieve lower values, one would need a shell type transformer. Upper levels for impedance could be any value from 10 to 24 % depending on the configuration and tapping range. Application in following industries : Chemical, Pharmaceuticals, Steel, Textile, Engineering, Plastic, Cement, Refineries, Mining, Captive Power Projects, Hydro Power Projects, Wind Mill Farms, Construction Houses, Pharma, Electrical, Electronics, Renewable Energy, Automobile.

Oil Filled Transformer

Get Price Quote

Oil filled transformer in harsh environments such as extreme temperatures, atmospheric pollution, and ultraviolet light has proved the reliability of Raychem terminations. The company is capable of manufacturing transformers to any other standards as per customers consultants requirement.

Porcelain Bushing Metal Parts

Get Price Quote

We are offering porcelain bushing metal parts.

Honeywell Ignition Transformer

2,000 Per Piece

01 Piece (MOQ)

Transformer Oil

Get Price Quote

This oil is produced through a multi stage continous refining process, clay contracting and vaccum filtration process.

reactor transformers

Get Price Quote

Air cored series & Shunt Reactor, Upto 2 MVA , Upto 33Kv, ONAN / AN A variable transformer, reactor having a core combining at least two complete core elements with a common yoke; primary winding divided into two independently fed sets of phase coils wound in opposite direction, arranged on symmetrical legs of core elements and separated by the common yoke; secondary winding with each phase coil divided into two wound in opposite direction portions carried by symmetrical core legs, adjacent to the primary coils and separated by common yoke. The secondary short-circuited reactor winding is reduced to at least one close loop member with loop portions separated by the common yoke. The single, poly phase apparatus has at least one primary coil per set that includes a controllable device in circuit relation therewith to enable control of one primary coil relative to the other, either in current magnitude or in current phase shift. The controllable device being either a silicon control rectifier or transistor.

Converter Duty Transformer

Get Price Quote

Drive Duty or Converter Duty Transformers are multi pulse & multi winding rectifier transformers. The number of Secondary windings can be 6, 9, 12, 15, 18 pulse or more for better harmonic cancellation. PRODUCT FEATURES Transformer with Multiple Secondaries Each Secondary has extended Delta that controls terminal voltage phase angle

Transformer Wire

Get Price Quote

TIW, a unique product for small transformers. Three layer extruded coatings of high performance polymer resins gives excellent dielectric properties to this type of winding wires. Unlike enamelled wires, three layers of insulation are extruded over the copper conductor with automated manufacturing process ensure perfect central position of conductor. The conventional enamelled wire winding coils requires insulation between the primary and secondary coils by means of barrier tape or interlayer tape to isolate primary and secondary windings. Since three layers coating is having very high dielectric strength, it has very less creepage factor. This positive feature of TIW serves to downsize switching transformers and promises high production efficiency and cost reduction. Depending on the design, the transformer size can be reduced up to 40% and weight up to 60% as compared to transformers made up of enamelled wires.

Voltage Auto Transformer

2,000 Per Piece

Current Transformer

Get Price Quote

1 Piece (MOQ)

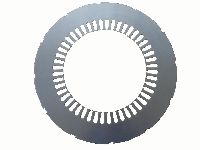

lamination core

Get Price Quote

Automotive as well as electrical steel with equipment sourced from Heinrich Georg GmbH Maschinenfabrik, Germany; Nittetsu Denji Corp., Japan and Esmech Pro eco, India. The Cold rolled steel (CR CRCA) and Hot rolled steel (HR) for automotive skin panels is sourced from leading steel mills domestically as well as from overseas. The CRGO steel (Cold rolled grain oriented steel) for transformers is sourced from Nippon Steel & Sumitomo Metal Corp. (NSSMC), Japan – the best in the world.

Used Transformer Oil

Get Price Quote

Transformer Oil or Dielectric Insulation Oil and other oils required for electrical machinery and installations can be manufactured using hydro finished base oils of group II +. The base stocks are selected based on viscosity requirements of the user. In colder countries pour point is also a critical property for base oil selection. Transformer Oil (TO) be used for filling the transformer with a primary objective of providing electrical insulation between the primary and secondary coils. Dissipation of heat generated during the process is also an important function. Electrical insulation is favored by high viscosity and heat dissipation is favored by low viscosity and circulation of fluid. Base oil viscosity at a compromise level is selected. Viscosity ranges for base oil slightly defer country to country, generally in the range of 10 to 40 cst. at 400 Degree C. During the service temperature of oil rises to about 60-800 Degree C. Viscosity of oil decreases due to temperature rise. Transformer has large extended surfaces exposed to atmosphere. The oil circulates through these tubes and dissipates heat into the atmosphere.

Welding Transformer

Get Price Quote

We are offering welding transformer. our range of welding transformers is manufactured by our reliable vendor base with the help of advanced technology controller. These transformers are quality tested on several parameters so as to deliver only superior range of products to our customers. We also offer customized solutions and best after sales service to cater to the requirements of our clients. Our comprehensive range of welding transformer has matchless features, including portable, pneumatically pirated, high precision, easy to operate, and need low maintenance cost. features low maintenanceeasy usageeasy access for inspectionperfect welding characteristicshigh efficiency welding machines range butt-welding machines: wire butt welders, band-saw blade welders, micro butt welders & heavy duty upset butt weldersmig/mag/co2 welding plantd. C. Rectifier welding machinesspot welding machines: portable hand operated, portable pneumatically pirated, high precision table mounted and pneumatically operated press type projection spot welding machineseam welding machinesarc welding transformers: air cooled welder, mini arc welder and oil cooled welder

Selec Current Transformer

Get Price Quote

1 Piece (MOQ)

Oil Filled Transformers

Get Price Quote

Oil Filled Transformers, Induction Furnace Transformers, lighting transformers

Current Transformers

Get Price Quote

Digital Clamp Meters, Digital Frequency Meter, Digital Multimeter

Low Tension Current Transformers

Get Price Quote

Low Tension Current Transformers, Transformers

Transformers

Get Price Quote

Transformers, Engineering Products, Engineering Equipments, Battery

Earthing Transformers

Get Price Quote

Earthing Transformers, Distribution Transformers, Power Transformers

Transformer

Get Price Quote

Transformer, Diesel Welding Generator, Rectifier, Diesel Generator

Transformer Oil

Get Price Quote

Raj group - we are counted among the proficient manufacturers of transformer oil in india.

Lt Current Transformers

Get Price Quote

Lt Current Transformers, switch board instruments

Transformer Oil

Get Price Quote

Cutting Oil, Greases, Hydraulic Oil, Industrial Lubricants

Color Coated Coil

Get Price Quote

Steel Wire Rods, Steel Slabs, Steel Product, Shredded Scrap

Crgo Lamination

Get Price Quote

Brass Transformer Parts

Get Price Quote

Brass Billet, Brass Extrusion Rod, Brass Ingot