Dry Type AC & DC Low Tension Current Transformer

Get Price Quote

1 Piece (MOQ)

Cast Resin Dry Type Transformer

Get Price Quote

In cast resin dry type transformers, the complete encapsulation of primary and secondary winding in epoxy resin prevents penetration of moisture into windings. The cast resin offers very good protection against adverse ambient conditions. These transformers can work without disruption of service at 100% humidity. Due to the high grade insulation material, coils are non hygroscopic & the transformer can be switched on directly without pre-drying even after a long period of service interruption. Contrary to the conventional dry type transformers the cast coil transformers are better in respect of impulse voltage withstand strength. Higher dynamic short circuit withstands strength as compared to oil immersed and conventional dry type transformers because of fibre glass reinforced epoxy encapsulation. No partial discharges can occur during operation. The insulation material used is glass fibre reinforced with epoxy resin of class 'F' which can withstand wide temperature variation. Due to high quality insulation material the transformer is practically non-inflammable by an electrical arc, special fire protection measures are not required.

Best Deals from Transformers

Dry Transformers

Get Price Quote

Industrial, Substation & Distribution purpose Manufacturing range Upto 2MVA 22 KV naturally air cooled.A dry type transformer has an iron core, vacuum pressure resin impregnated high voltage windings and low voltage windings . The low voltage winding is constructed with conductors. Dupond nomex insulating material includes an apparatus to secure the windings in place during a vacuum and pressure resin impregnation process. The result is a coil that exhibits high short circuit protection due to the tightly bond conductors comparable to completely resin encased molded transformers at a substantially reduced cost.

Power Transformers

Get Price Quote

Station & Multi-winding to suit specific needs & L.T. Transformers for generating Stations. Upto 10 MVA ,3 Phase , Upto 33Kv , ONAN / ONAF / OFAF /OFWF Cooling A power transformer characterized by inner and outer low voltage winding sections and a high voltage winding section disposed there between. The low voltage windings are comprised of a plurality of pancake coils, and the high voltage winding are comprised of a plurality of conductor strands spirally wound for a plurality of coil layers. The low and high voltage winding sections are laterally spaced with the low voltage windings disposed in side-by-side positions and adjacent to the high voltage windings. The high voltage windings having a smaller turn height than the low voltage windings and having conductor strands of smaller gauge than the pancake coils of the low voltage windings.A Power transformer is an electrical device that transfers energy between two or more circuits through electromagnetic induction.A varying current in the transformer's primary winding creates a varying magnetic flux in the core and a varying magnetic field impinging on the secondary winding. This varying magnetic field at the secondary induces a varying electromotive force (EMF) or voltage in the secondary winding. Making use of Faraday's Law in conjunction with high magnetic permeability core properties, transformers can thus be designed to efficiently change AC voltages from one voltage level to another within power networks. Transformers range in size from RF transformers less than a cubic centimeter in volume to units interconnecting the power grid weighing hundreds of tons. A wide range of transformer designs is encountered in electronic and electric power applications. Generation of electrical power in low voltage level is very much cost effective. Hence electrical power is generated in low voltage level. Theoretically, this low voltage level power can be transmitted to the receiving end. But if the voltage level of a power is increased, the electric current of the power is reduced which causes reduction in ohmic or I2R losses in the system, reduction in cross sectional area of the conductor i.e. reduction in capital cost of the system and it also improves the voltage regulation of the system. Because of these, low level power must be stepped up for efficient electrical power transmission. This is done by step up transformer at the sending side of the power system network. As this high voltage power may not be distributed to the consumers directly, this must be stepped down to the desired level at the receiving end with the help of step down transformer. These are the uses of electrical power transformer in the electrical power system.Two winding transformers are generally used where ratio between high voltage and low voltage is greater than 2. It is cost effective to use auto transformer where the ratio between high voltage and low voltage is less than 2. Again three phase single unit transformer is more cost effective than a bank of three single phase transformer unit in a three phase system. But still it is preferable to use than the later where power dealing is very large since such large size of three phase single unit power transformer may not be easily transported from manufacturer's place to work site.The high reliability of these transformers ensures maximum availability, lower maintenance costs and reduced life-cycle costs. Our ultimate goal is to exceed our customers' expectations continually by delivering the highest quality services. Power transformers comply with our quality policy by:Consistent management focus on quality;Continually improving the effectiveness of our Quality Management System;Understanding our customers goals and embracing them.

Transformer Oil

Get Price Quote

This oil is produced through a multi stage continous refining process, clay contracting and vaccum filtration process.

Encapsulated Current Transformers

15,000 Per Piece

Welding Transformer

Get Price Quote

We are offering welding transformer. our range of welding transformers is manufactured by our reliable vendor base with the help of advanced technology controller. These transformers are quality tested on several parameters so as to deliver only superior range of products to our customers. We also offer customized solutions and best after sales service to cater to the requirements of our clients. Our comprehensive range of welding transformer has matchless features, including portable, pneumatically pirated, high precision, easy to operate, and need low maintenance cost. features low maintenanceeasy usageeasy access for inspectionperfect welding characteristicshigh efficiency welding machines range butt-welding machines: wire butt welders, band-saw blade welders, micro butt welders & heavy duty upset butt weldersmig/mag/co2 welding plantd. C. Rectifier welding machinesspot welding machines: portable hand operated, portable pneumatically pirated, high precision table mounted and pneumatically operated press type projection spot welding machineseam welding machinesarc welding transformers: air cooled welder, mini arc welder and oil cooled welder

Toroidal Transformer

500 - 2,000 Per Piece

500 Piece (MOQ)

Toroidal Transformer offer many advantages over a conventional laminated transformer.Toroidal has a round shape with no air gaps,and with the primary and secondary windings uniformly ditributed around the core,"locks in" the magnetic field and makes the toroidal transformer very quiet and efficient.Toroidal Transformer,by meeting today"s requirements for smaller,more efficient,quieter and safer products,are being accepted in an increasing range of electronic and electrical equipment.With toroidal transformer smaller dimensions, lighter weight and low stray magnetic fields, you can build more compact,lower cost quality products without sacrificing performance.Basics of Toroidal TransformerToroidal transformers are built around a ring-shaped core, which, depending on operating frequency, is made from a long strip of silicon steel or permalloy wound into a coil, powdered iron, or ferrite core. A strip construction ensures that the grain boundaries are optimally aligned, improving the transformer's efficiency by reducing the core's reluctance. The closed ring shape eliminates air gaps inherent in the construction of an E-I core. The cross-section of the ring is usually square or rectangular, but more expensive cores with circular cross-sections are also available. The primary and secondary coils are often wound concentrically to cover the entire surface of the core. This minimizes the length of wire needed, and also provides screening to minimize the core's magnetic field from generating electromagnetic interference.

Medium Voltage Current Transformer

Get Price Quote

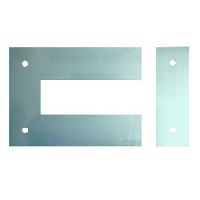

ei lamination core

Get Price Quote

We are the prominent manufacturers of UI Lamination core that is used in manufacturing transformers. The core is fabricated using superior quality raw material. The high grade electrical steel is used to maintain low watt losses and low off load current. Available in various grades and specifications, the core is fabricated using high grade CRNO coils. The superior construction standards, Fine cutting provides easy usage during the assembly stages and leaves no air gap. The lamination core is acknowledged for application specific design, dimensional accuracy, hassle free operation and easy installation. We also provide customization, to suit the specific requirements of clients. Precise dimensions and application specific design make the lamination appropriate for usage in transformer manufacturing industry, inverter UPS manufacturing industry and stabilizers manufacturing industry. EI lamination is made by the silicon steel strip. The gap sizes of transformer lamination core can be customized. Vedanta Electricals specializes in the production of transformer lamination, transformer core lamination core, such as EI lamination in standard sizes and non-standard sizes.

Hermetically Sealed Transformer

Get Price Quote

Hermetically Sealed Transformer, Distribution Transformers

Current Transformer

Get Price Quote

1 Piece (MOQ)

Auxiliary Transformer

Get Price Quote

The Unit Auxiliary Transformer is the Power Transformer that provides power to the auxiliary equipment of a power generating station during its normal operation. This transformer is connected directly to the generator out-put by a tap-off of the isolated phase bus duct and thus becomes cheapest source of power to the generating station. It is generally a three-winding transformer i.e. one primary and two separate secondary windings. Primary winding of UAT is equal to the main generator voltage rating. The secondary windings can have same or different voltages i.e. generally 11KV and or 6.9KV as per plant layout.

Low Tension Current Transformers

Get Price Quote

Low Tension Current Transformers, Transformers, Current Transformers

Current Transformers

15,000 Per Piece

Honeywell Ignition Transformer

2,000 Per Piece

01 Piece (MOQ)

Transformer Oil

Get Price Quote

Selec Current Transformer

Get Price Quote

1 Piece (MOQ)

Digital Tap Position Indicators

Get Price Quote

Digital Tap Position Indicators, moving coil panel meters

lighting transformers

Get Price Quote

lighting transformers, Oil Filled Transformers, Cast Resin Transformers

Aircooled Transformer

Get Price Quote

Aircooled Transformer, Auto Voltage Transformer, Testing Instrument

Transformer Oil

Get Price Quote

Transformer Oil, Industrial & Automotive Grease, bearing oils, Base Oil

tape insulated transformers

Get Price Quote

tape insulated transformers, abs minel transformers, cbct transformers

Dimmerstat

Get Price Quote

Dimmerstat, PT testing unit, transformers repairing services

substation equipment

Get Price Quote

substation equipment, flat busbar, Electrical Connector

Transformer Oil

Get Price Quote

Raj group - we are counted among the proficient manufacturers of transformer oil in india.

Hermetically Sealed Transformer

Get Price Quote

Hermetically Sealed Transformer

Transformer

Get Price Quote

Transformer, back light, cable glands connector

High Frequency - Low & High Power Transformers

Get Price Quote

High Frequency - Low & High Power Transformers, litz wires, Capacitors - Film

Transformers

Get Price Quote

Transformers, insulation products, Commutators, AC Motors