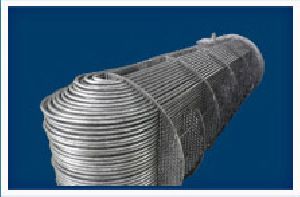

U Tube Bundle Heat Exchanger

Get Price Quote

U Tube Bundle Heat Exchanger that have hold the advantage of efficient usage of space. These U tube bundle heat exchangers have less pressure drop and lower energy costs. This exchanger is very versatile and is used in various processes. These U bundle heat exchangers can be availed from us in reasonable rates.

Finned Tube Heat Exchanger

4,000 Per Piece

1 Piece (MOQ)

Best Deals from Tube Heat Exchangers

Shell & Tube Heat Exchanger

Get Price Quote

Shell and tube heat exchanger in their various construction are probably the most widespread and commonly used basic heat exchanger configuration in the process industries. The reasons for this general acceptance are several. The shell and tube heat exchanger provides a comparatively large ratio of heat transfer area to volume and weight. It provides this surface in a form which is relatively easy to construct in a wide range of sizes and which is mechanically rugged enough to withstand normal shop fabrication stresses, shipping and field erection stresses, and normal operation conditions.There are many modifications of the basic configuration, which can be used to solve special problems. The shell and tube heat exchanger can reasonably easily clean, and those components most subjects to failure – gasket and tubes – can be easily replaced. Finally, good design method exists, and the expertise and shop facilities for the successful design and construction of shell and tube heat exchanger are available. Different no. of passes can also be given depending on the size and requirement of the Heat exchanger.

Shell & Tube Heat Exchanger

Get Price Quote

Tube Heat Exchanger

Get Price Quote

Shell & Tube Type Condenser is used to condense the vapor emerges out during the operation. It mainly works through condensing the vapors flow through tubes where they are treated with cooling water over external surface.A condenser is a device that converts vapor into the liquid state whereas a heat exchanger is a device that is used for heat recovery also to transfer heat from two fluids. Heat exchanger only heat is transferred without phase change and heat is transferred along with the phase change in the condenser.There are three types of condensers: air-cooled, water-cooled and evaporative. Air-cooled Water-cooled Evaporative Heat is transferred via solid material (conduction), liquids and gases (convection), and electromagnetic waves (radiation). Heat is usually transferred in a combination of these three types and seldomly occurs on its own.

Shell and Tube Heat Exchanger

5,000 - 100,000 Per Piece

1 Set (MOQ)

Shell & Tube heat exchangers offer large surface area in combination with efficient heat transfer and compactness. These are widely used in industries for various duties like cooling, heating, condensation, evaporation etc. Garg are the pioneers in the field of glass shell and tube heat exchangers in India and their product has wide market acceptability. Salient Features : 1.Universal corrosion resistance an excellent alternative to expensive MOCs like graphite, hastelloy, copper titanium, tantalum and other exotic metals. 2. Excellent heat transfer as fouling does not occur on smooth glass surfaces. 3. Flexibility of installation vertical/horizontal. 4. Easy replacement of tubes for repair and cleaning. 5. Available in wide range of HTAs. 6. Ease of installation due to light weight. 7. Economical. 8. Suitable for applications where large HTAs are required in limited space. Advantages Over Conventional Coil Type Heat Exchangers : 1. The overall heat transfer coefficient in shell and tube heat exchanger is about 3 times higher than in coil type heat exchanger. 2. The pressure drop in shell and tube heat exchanger is minimal compared to 2-3 kg/cm2 in coil side of coil type heat exchanger. 3. For requirement of higher heat transfer areas shell and tube heat exchanger is the only alternative.

Tube & Shell Heat Exchangers

80,000 Per Piece

1 Piece(s) (MOQ)

A Shell and Tube Exchanger consists of a number of tubes mounted inside a cylindrical shell. Two fluids can exchange heat, one fluid flows over the outside of the tubes while the second fluid flows through the tubes. The fluids can be single or two phase and can flow in a parallel or a cross/counter flow arrangement. The popularity of shell and tube exchangers has resulted in a standard being developed for their designation and use. This is the Tubular Exchanger Manufactures Association (TEMA) Standard. Our on-going research and superior engineering makes our shell & tube heat exchangers the best.

Tube Heat Exchanger

Get Price Quote

Shell and Tube Heat Exchanger

Get Price Quote

Shell and tube is the most advanced technology available and is specifically engineered for particular applications. Heat exchangers are commonly used for the transfer of heat in industrial process applications. They are available in a variety of diameters and lengths. The U-tube heat exchangers are designed for a wide range of liquid to liquid and steam to liquid applications. The shell and tube heat exchanger is constructed using copper tubes and a carbon steel shell. It is manufactured using tide range of applications. Features U-tube construction Units designed for liquid to liquid and steam to liquid applications Available in 2 or 4 pass construction Removable tube bundles for convenience in cleaning and inspection. Strong, durable construction with copper steel tubes and rugged cast-iron or steel head in standard units. (Optional materials are available) Coil and baffle arrangements designed to maximize heat transfer performance. Tubes expanded into stationary tube sheet allow for tube expansions and contractions, due to thermal fluctuations, without causing stresses on the joints. Welding tubes to the tube sheet is optional. Advantages The advantage of the shell and tube design cannot be ignored. Each unit comes with Connections that come in standardized sizes for easy assembly and feature additional thread and surface protection for clean installation U-bend tubes expanded into a tube sheet which allow for tube expansions and contractions due to thermal fluctuations Gaskets that are made of high quality compressed fibres which lends to reusability A standard cast-iron or steel head for heavy duty services (also available as a spare part) Saddle attaches which make for quick and easy mounting Punched baffles with minimal clearances between tubes guaranteeing correct fluid flow and minimized bypass A welded shell protected with high quality paint for corrosion resistance Copper steel tubes which allow for strong, durable performance over a wide range of applications. Unique tube bundle layout (chevron corrugated pattern) minimizes deposit buildup at the edges and optimises media flow for high velocity flow turbulence. Applications Shell and tube heat exchangers are frequently selected for such applications as: * Process liquid or gas cooling * Process or refrigerant vapor or steam condensing Process liquid, steam or refrigerant evaporation Process heat removal and preheating of feed water Thermal energy conservation efforts, heat recovery Compressor, turbine and engine cooling, oil and jacket water Hydraulic and lube oil cooling. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed by several types of tubes: plain, longitudinally finned, and other types.

Tube Heat Exchangers

Get Price Quote

Shell & Tube Heat Exchangers

Get Price Quote

The Shell & Tube Heat Exchangers that we deal in are designed using top-notch quality stainless steel and carbon steel under the supervision of experts. We are a reckoned Manufacturer, Exporter and Supplier of Shell & Tube Heat Exchangers from Maharashtra, India. Our Heat Exchangers are suitable for elevated pressure and temperature applications so as to exchange the heat impeccably from a medium to the other. Order retail or bulk, timely delivery is guaranteed!

Tube Heat Exchanger

150 Per Kilogram

Shell Tube Heat Exchanger

Get Price Quote

Shell & Tube Heat Exchangers are popular in chemical industries because they occupy less space and offer reasonable pressure drop. The apparatus consists of fabricated M.S. shell, inside which copper tubes with baffles are fitted. Hot water is obtained from a set of gysers provided with setup. This is two pass type exchanger so that hot water passes to one end of shell through tubes and returns to another end through remaining water. The cold water is admitted at the bottom of shell, which passes over hot water tubes. Control valves are provided to control the flow rates of hot water and cold water. Measuring tank is provided to measure flow rates. The unit is mounted on a sturdy stand. Specifications Shell - Material - M.S. Inner Dia. - 208mm Thickness - 6mm Length - 500mm 25% baffles at 100m distance - 4No. Tubes - Material - Copper I.D. - 13mm, O.D. - 16mm approx. Length - 500mm No. of Tubes - 24 Thermometers - 4 No. , 0 to 1000c Gysers - 3KW cap. - 2No. Measuring Tank Experimentation Determination of heat transfer coefficient for inner and outer surface of tubes. Study of variation of heat transfer coefficient with type of flow. Service Required Continuous water supply at rate of 50 lpm at constant head. Floor Space - 2m X 1m 15 Amp. , 230 V.A.C. power supply

Titanium Tubes Heat Exchangers

Get Price Quote

We are offering item: titanium tubes heat exchangers total qty: 3 nos shell ft dish: sa 516 gf 70 channel & floating head dish: sa 516 gr. 70 + sb 127 clad tube: sb 338 gr. 2 tube sheet: sa 266 cl. 4 + 265 gr. R. Clad & sb 171 uns c63000 flange: sa 266 gr. 2 sa 336 f11 cl 2 sa 336 f11 cl 2 + ss321 clad baffles: sa 171 uns c46400 flange: sa 266 cl. 4, sa 266 cl. 4 + monel weld deposit, sa 105 & sa 105 + monel weld diposit third party inspection: lloyd's register asia

Glass Shell and Tube Heat Exchanger

50,000 Per Set

1 Set (MOQ)

Finned Tube Heat Exchanger

950 Per Piece

Stainless Steel Seamless Heat Exchanger U-Tubes

Get Price Quote

Stainless Steel Seamless Heat Exchanger ‘U’-Tubes the straight tubes are bent on a pulley of known radius. Thereafter, the bend portion plus 6 inch leg length is stress relieved by resistance heating, The temperature is controlled and maintained with the help of suitable Pyrometer at required temperature and time. Inert gas is passed through it at the required flow rate to avoid inside oxidation.

INDUSTRIAL TUBE HEAT EXCHANGER

100,000 Per Pieces

Shell & Tube Heat Exchangers

Get Price Quote

From simple Oil Coolers to complex Shell and Tube Heat Exchangers. Heft can design and manufacture heat exchangers related to almost all industrial application. DesignHeft, specially developed software carries out calculations related to minor aspects of mechanical and thermal designs of heat exchangers. The software works according to ASME & TEMA STANDARDS. Size and Types The sizes range from 2" OD to a few meters, in a single or multiple pass. Tubes can be straight or 'U' bundle. Fixed-Tube Sheet Design. Full-Through Floating-Head Design. Split-Ring Floating-Head Design. Bayonet Tube Design. MaterialHeat Exchangers are fabricated in Hastealloy, Inconel, all grade of Stainless Steel & Carbon Steel & any other weldable material operating in moderately high pressure and temperature range.

Steel Tube Heat Exchanger

Get Price Quote

SILICON CARBIDE TUBE HEAT EXCHANGER

Get Price Quote

Silicon Carbide Shell and Tube Heat Exchanger (Di-Sic)For highly corrosive environments like Acids including H2SO41 HNO31 HF1 HCL, etc. Bases including KOH, NaOH, Metallic Salts and also in Solvent Atmosphere.Advantages of Di-Sic Heat Exchanger Over Other Heat Exchangers•Highest Thermal Conductivity•Equal to that of commonly used graphite tube but far better than other materials available•2 times that of Tantalum•5 times that of Stainless Steel•5 times that of Hastelloy•15 times that of Glass•Unsurpassed advantages over Metals, Glass and other Tube Materials for enhanced efficiency and reliability•Tubes are proof tested to over 150 bar to assure reliability and added safety -High Overall Heat Transfer Co-efficient5m² Di-Sic Heat Exchanger successfully working over past 3 yearsHighly Resistant to Thermal Shock• It has high thermal Conductivity and low Co – efficient of Thermal Expansion. It has go high resistant to thermal shocks and can survive rapid thermal cycles as compared to other materials• No impregnation and hence does not contaminate process ingredients. Suitable for API Manufacturing• Available in standard models to withstand pressure ranging from 6Kg/cm²g to Full Vacuum Erosion ResistanceSilicon Carbide Tube is 50% harder than Tungsten Carbide and 10 times harder than Conventional Stainless Steel.This extreme hardness combined with high purity and fine micro-structure makes for resistance to wear and erosion under mechanically abrasive conditions.Chemical ResistanceA Single – Phase, Alpha – Sintered Silicon carbide offering high purity, fine grain and extremely low porosity to enhance the chemical resistance. Test shows that even in highly corrosive chemicals, the corrosion loss does not exceed 2.5mg/cm per year which can give Long Term Service.If you'd like to know more......For more information about Silicon Carbide Heat Exchanger, or to discuss your specific application, contact us. Our Engineers will work with you to analyze your particular requirements and determine the most cost effective solution.

Shell Tube Heat Exchanger

450,000 Per unit

1 unit (MOQ)

Fin Tube Heat Exchangers

Get Price Quote

We are offering fin tube heat exchangers.aluminum fin, copper tube heat exchanger pipe size 3/8, 1/2, 5/8 fin material aluminum, copper, ss, haider or distributor as required.

Finned Tube Heat Exchanger

Get Price Quote

The Finned Tube Heat Exchangers of are used for both cooling and heating of air, water and gas. We offer these in different forms including continuous spiral wound fins, G type, L type and wire wound fins. The materials used for manufacturing the tubes are aluminum, copper, SS, admirably brass, carbon steel, cupro nickel etc.

U Tube Heat Exchanger

105,000 Per Piece

Shell and Tube Heat Exchangers

Get Price Quote

Sunraj Industries exports shell and tube heat exchangers in various requriments like “U” tube heat exchangers, straight tube “fixed” tubesheet exchangers and straight tube “floating” tubesheet exchangers. These units are manufacture to provide high thermal efficiency and we give rugged construction for tough day to day operations. Sunraj offer you total flexibility to meet your most demanding requirements…special connection sizes and locations, various tube connection sizes and locations, various tube diameters and spacing, tube lengths, and special materials.

Fin Tube Heat Exchangers

10,000 Per Piece

shell tube heat exchangers

Get Price Quote

shell tube heat exchangers, Chemical Reactors, Reactors, Process Pumps

Shell & Tube Heat Exchanger

Get Price Quote

Shell & Tube Heat Exchanger, Orifice Plates, Multi Column Distillation Plant

Shell and Tube Heat Exchanger

Get Price Quote

We are a renowned name as the Manufacturer, Supplier and Exporter of Shell and Tube Heat Exchanger based in Mumbai, Maharashtra. The Shell and Tube Heat Exchanger we provide is widely appreciated for their sturdy construction, robust designs and high precision. We can fulfil the bulk demands of exchanger by our clients easily. SHELL AND TUBE Heat Exchangers, they can be used for variety of applications, namely, Condensation, Cooling, Heating, Boiling and suitable combinations of the above. The selection of equipment depends upon the type of application, heat load, availability of heating/cooling media etc. In all types of glass Heat Exchangers the heat transfer is through the wall of the glass tube. The heat transfer co-efficient can be of a moderate order because of low wall thickness. With 1.5 mm thick walled tubes, the wall heat transfer co-efficient is about 725 Kcals/hr m2 oC and we can obtain an overall heat transfer co-efficient for steam condensation with water-cooling as about 550 Kcals/hr m2 oC. The allowable pressure inside the tubes can be vacuum to 3 kg/cm2 while that on the domes as well as on the shell depends upon the size of the shell corresponding to the values mentioned in Technical Specifications. The Heat Exchangers can safely be used up to 150o C with the limitations of Thermal Shock up to 120o C and temperature gradient across the wall less than 50o C. The shell side pressures on Metallic Shell & Tube heat exchangers can be as high as 2.5 kg/cm. For higher pressure requirement up to 4 kg/cm2, the PTFE tube sheets need redesigning and can be made on special request Range of the Models : Shell & Tube Heat Exchangers Type RGM Shell & Tube Heat Exchangers Type RGG Shell & Tube Heat Exchangers Type RMG